Disc ridging and fertilizing machine

A technology of ridge fertilization and disk, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of low production efficiency, large soil contact area, and large power consumption, so as to improve work efficiency and production efficiency, reduce Small soil contact area, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

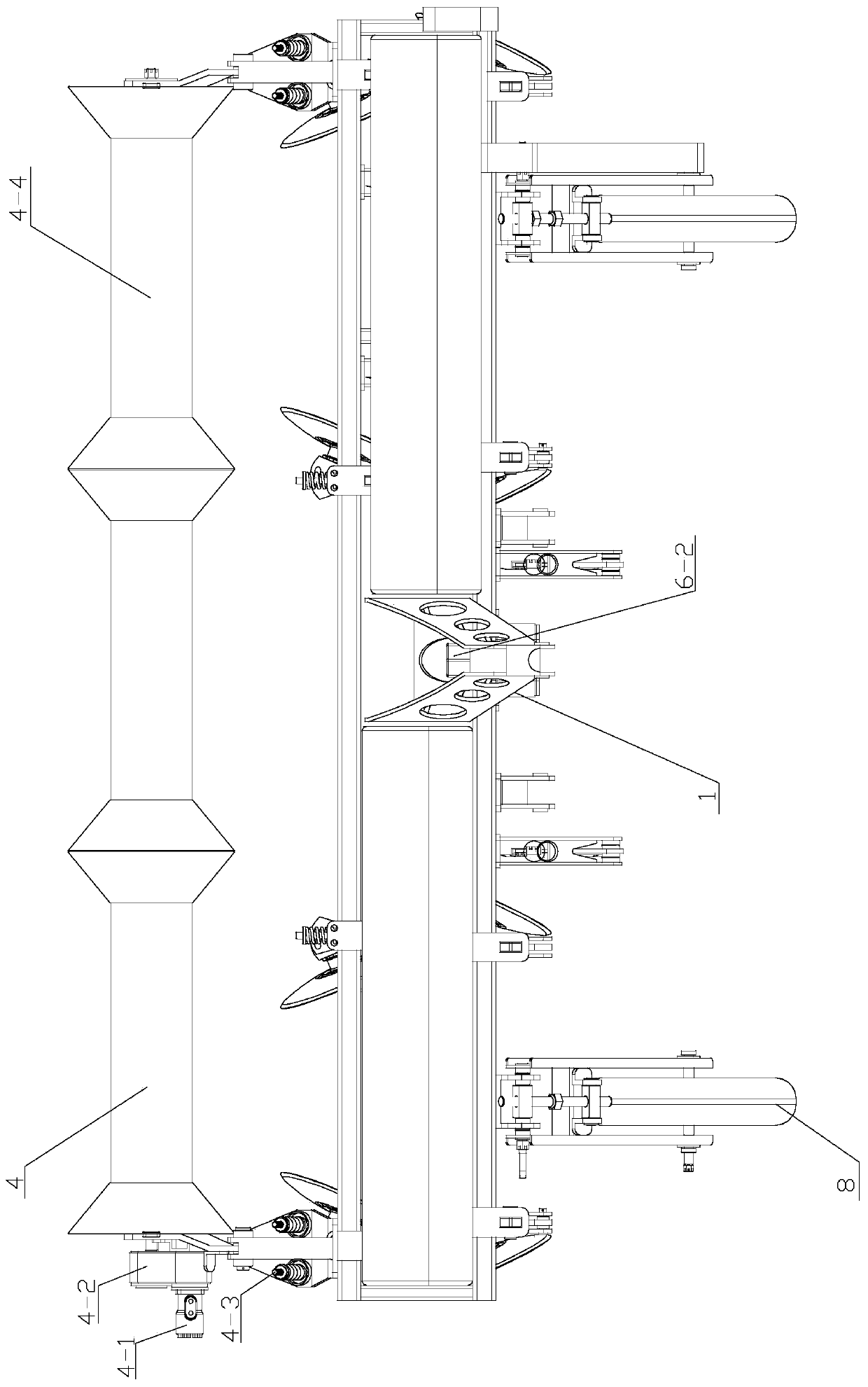

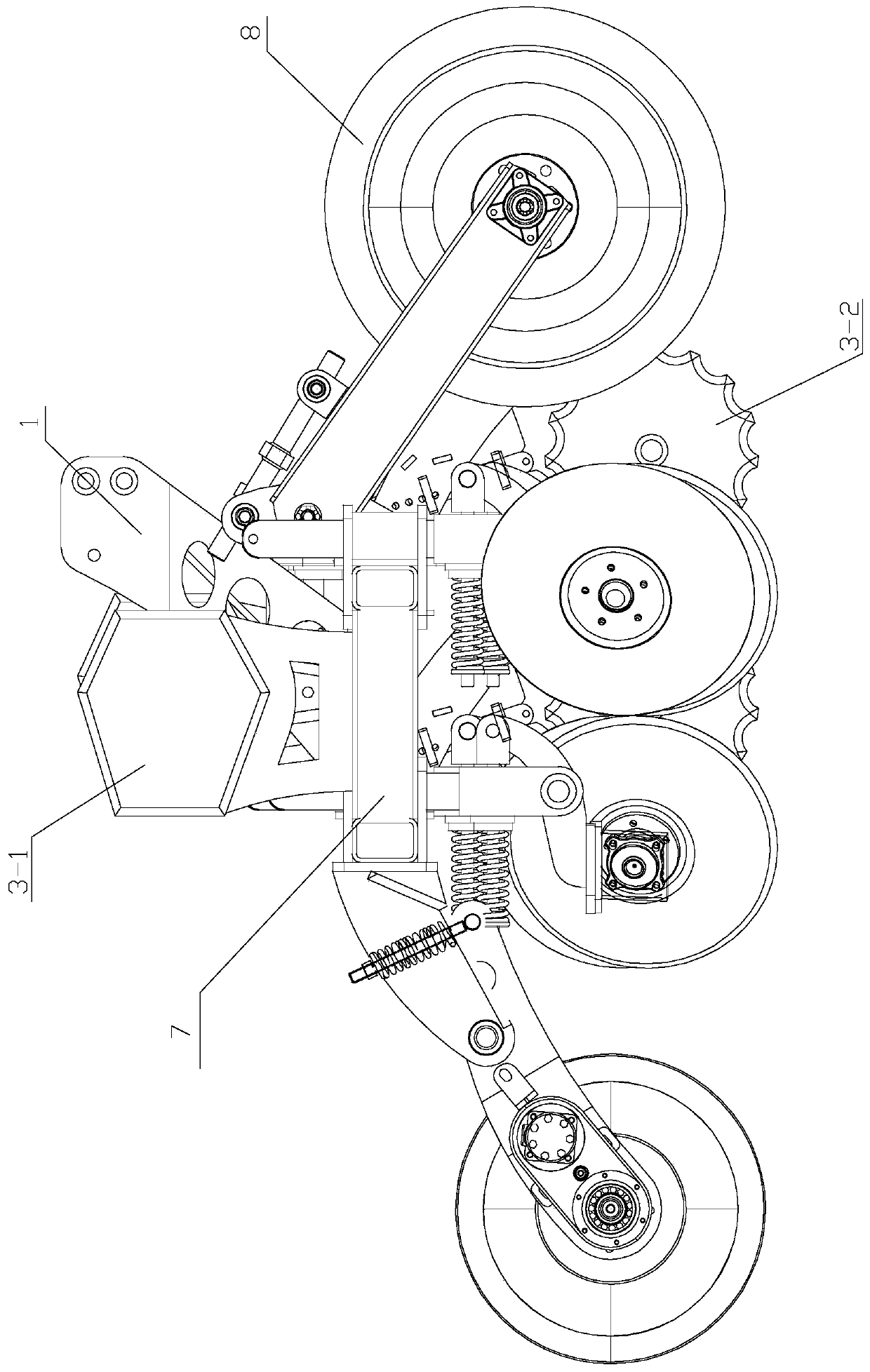

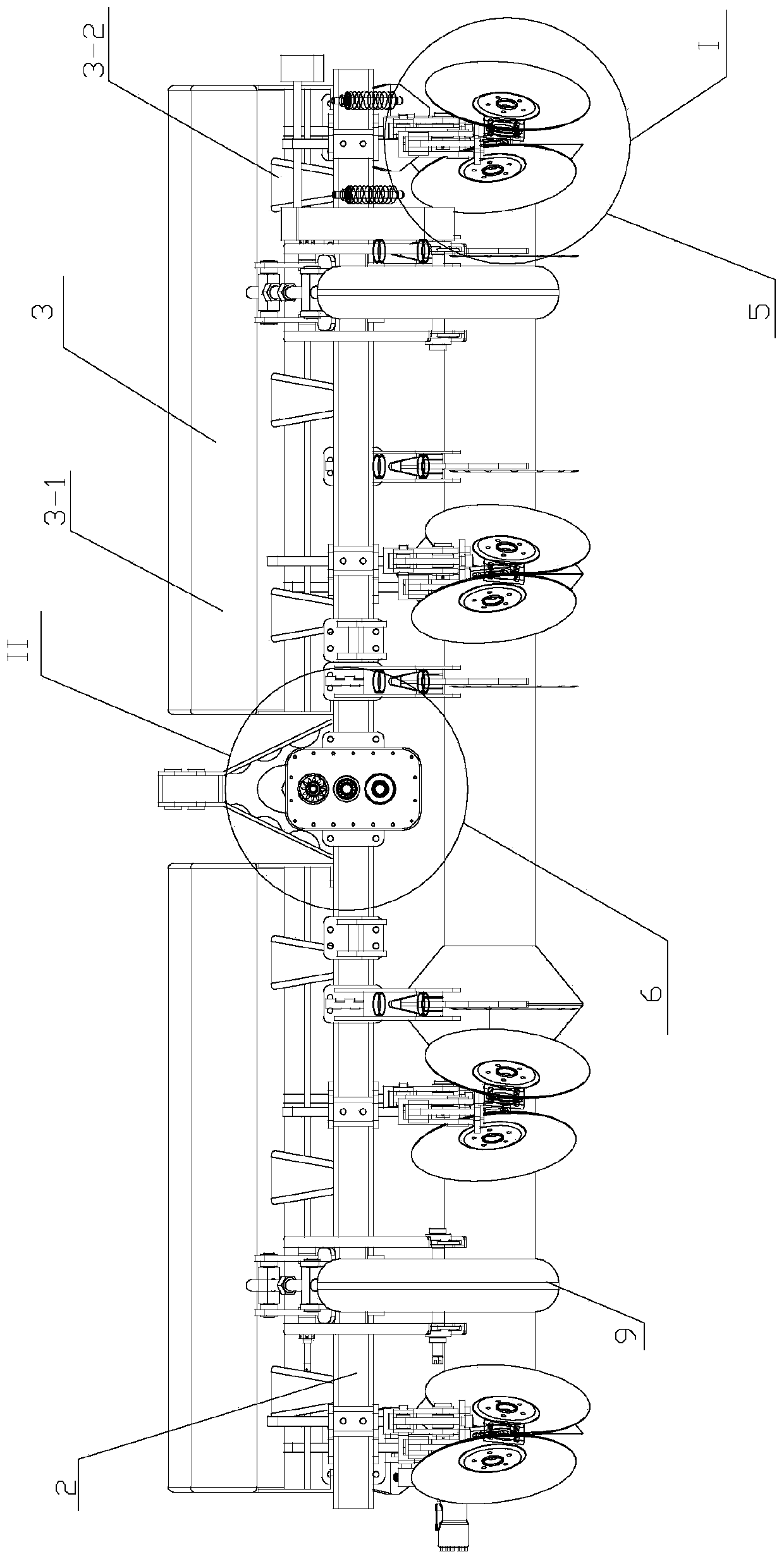

[0019] Specific implementation mode one: combine Figure 1 to Figure 3 Describe a disc ridge fertilization machine of this embodiment, which includes a hanger assembly 1, a main frame 2, a fertilization assembly 3, a shaping assembly 4, a power assembly 6, N soil-distributing disk assemblies 5 and two sub-frames 7. N is an integer greater than or equal to 1;

[0020] Suspension frame assembly 1 is installed on the middle upper part of main frame 2, and two sub-frames 7 are installed on the both sides of main frame 2, and two sub-frames 7 are hinged with main frame 2, and the upper surface of two ends of main frame 2 is set respectively There is a fertilization assembly 3, the center of the main frame 2 is provided with a power assembly 6, the soil distribution assembly 5 is evenly distributed on the front beams of the main frame 2 and the two sub-frames 4, and the shaping assembly 4 is arranged on the main frame in a straight line. Frame 2 and the rear beams of the two sub-fr...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 Describe this embodiment. The shaping assembly 4 in this embodiment includes a motor 4-1, a pressing roller drive box 4-2, a No. 1 pressing roller frame 4-3, a No. 2 pressing roller frame 4-5, and a pressing roller 4-4. ;

[0022] The two ends of the main frame 2 are respectively connected with a suppression roller frame 4-3, one end of the suppression roller 4-4 is connected to the inner side of the No. 1 suppression roller frame 4-3, and the other end of the suppression roller 4-4 is connected to the No. 2 suppression roller frame The inner side of 4-5, one side of the suppression roller drive box 4-2 is connected to the outside of the No. 1 suppression roller frame 4-3, and the other side of the suppression roller drive box 4-2 is connected to the motor 4-1.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, the soil distribution disc assembly 5 described in this embodiment includes a plow column 5-1, a soil distribution disc 5-2 and a soil distribution disc hub 5-3;

[0024] One end of the plow column 5-1 is fixedly connected with the main frame 2 and the sub-frame 7, and the two sides of the other end of the plow column 5-1 are respectively fixedly connected with a sub-soil pan hub 5-3, and the sub-soil pan 5-2 is set On the sub-soil disc wheel hub 5-3, a pair of sub-soil discs 5-2 become V-shaped and are installed on the plow column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com