Sphere material roundness sorting machine

A sorting machine and material technology, which is applied in solid separation, classification, chemical instruments and methods, etc., can solve the problems of mixing ellipsoids, easy accumulation and sorting work, difficult to continue to effectively carry out, etc., and achieves simple and compact structure and good finished products. High efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

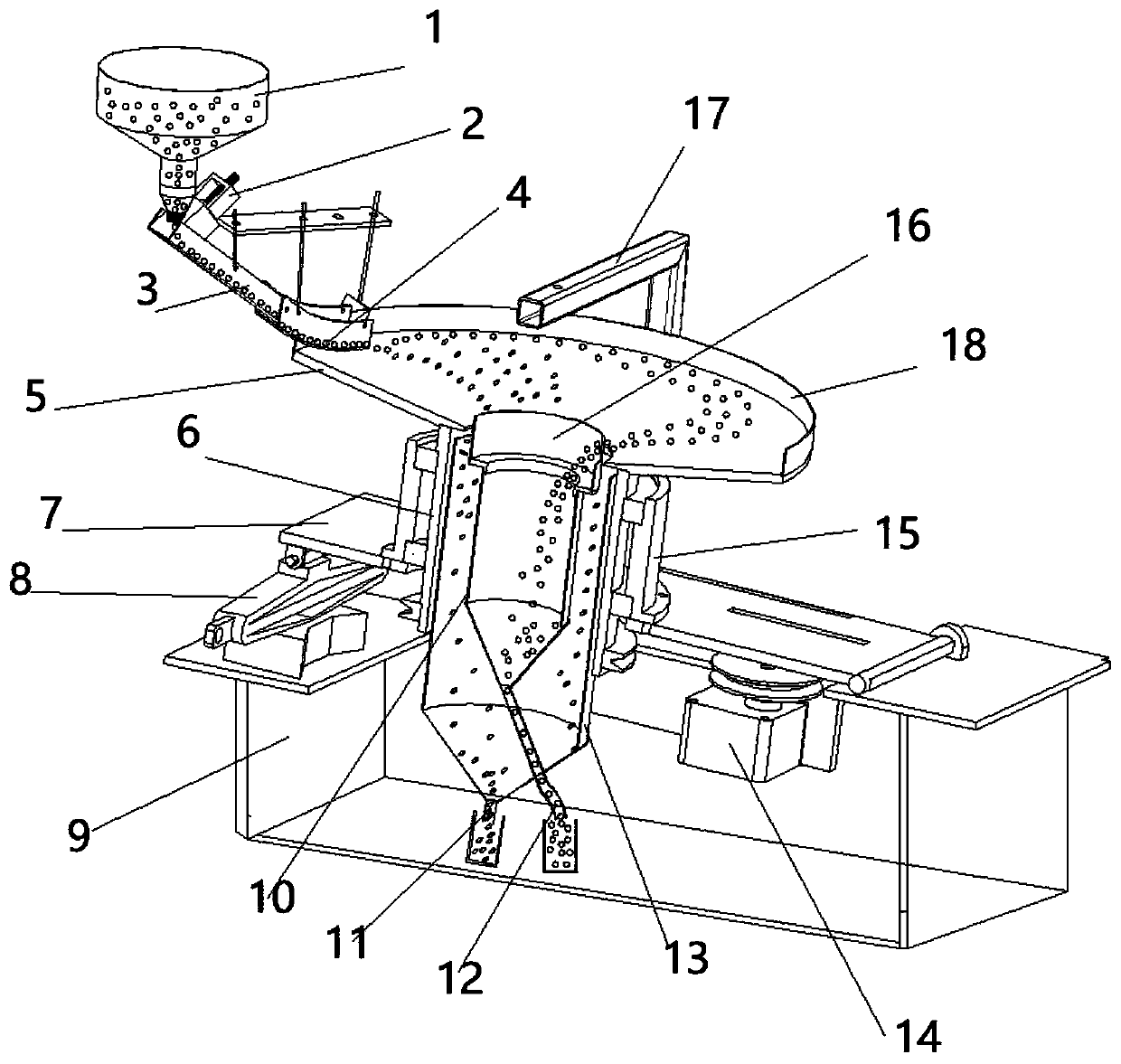

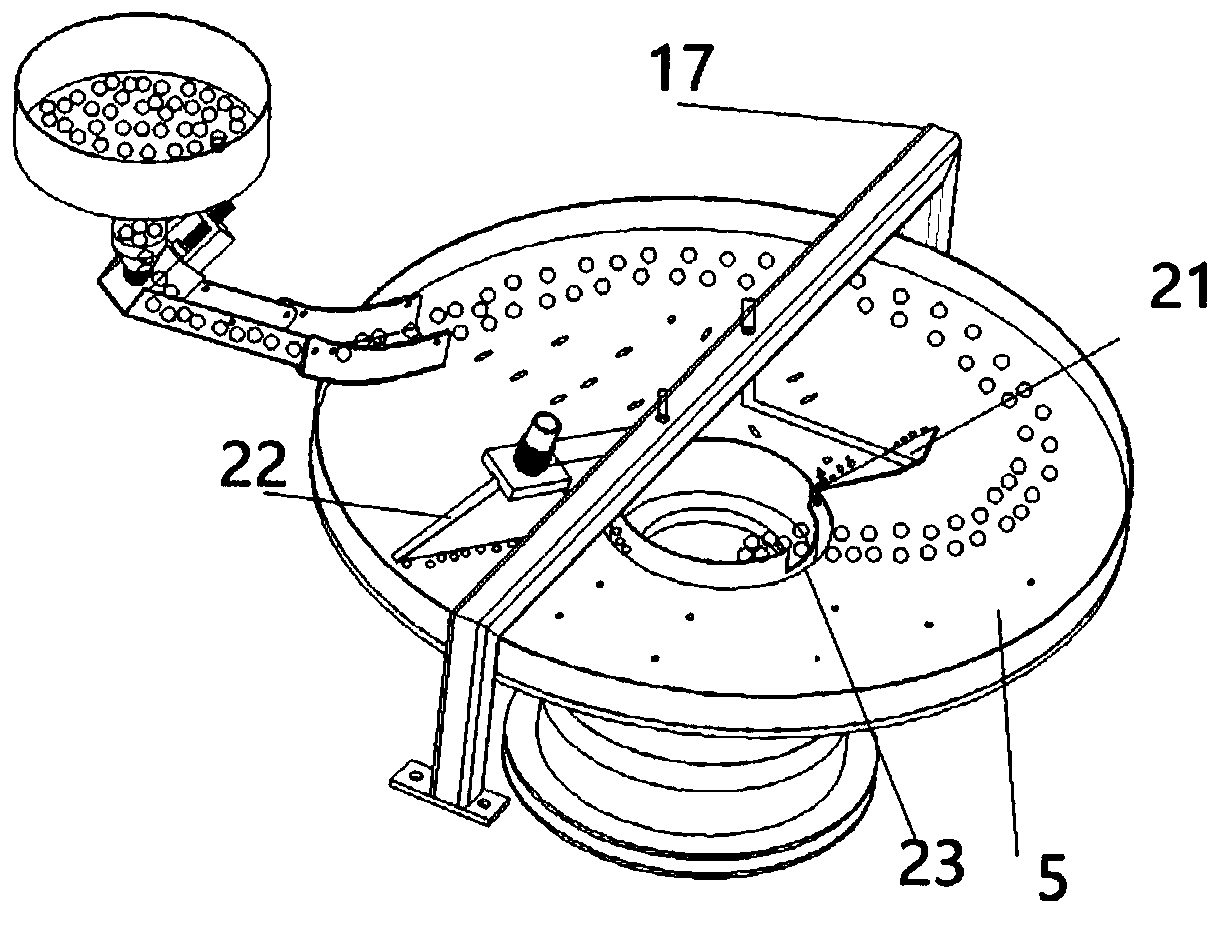

[0030] like figure 1 , 2 As shown, a spherical material roundness sorting machine includes a base frame 9, a storage hopper 1, a feeding trough, a conical sorting disc 5, a retaining ring, a driving motor 14, a rotating bearing 6, and a shaft sleeve 15 , axle sleeve mounting plate 7, waste bin 13, and finished product barrel 10; On the base frame 9, storage hopper 1, feeding trough, conical sorting disc 5 and waste bin 13 are installed successively from top to bottom. The storage hopper 1 is fixed by a mounting bracket 17 positioned on the top of the base frame body 9 .

[0031] The lower chute is located below the outlet of the storage hopper 1 and is also fixed by the mounting frame 17 on the top of the base frame body 9 . In order to adjust the initial velocity when the sphere raw material enters the conical sorting disc 5, the inclination of the lowering chute is set to be adjustable. Specifically, the lowering chute is composed of a first chute 3 and a second chute 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com