A precision metal tank shaping device

A technology for shaping devices and tanks, which is applied to household appliances, hollow objects, and other household appliances, etc. It can solve the problems of low product qualification rate, abrasive dust cleaning, poor quality of tank shaping, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

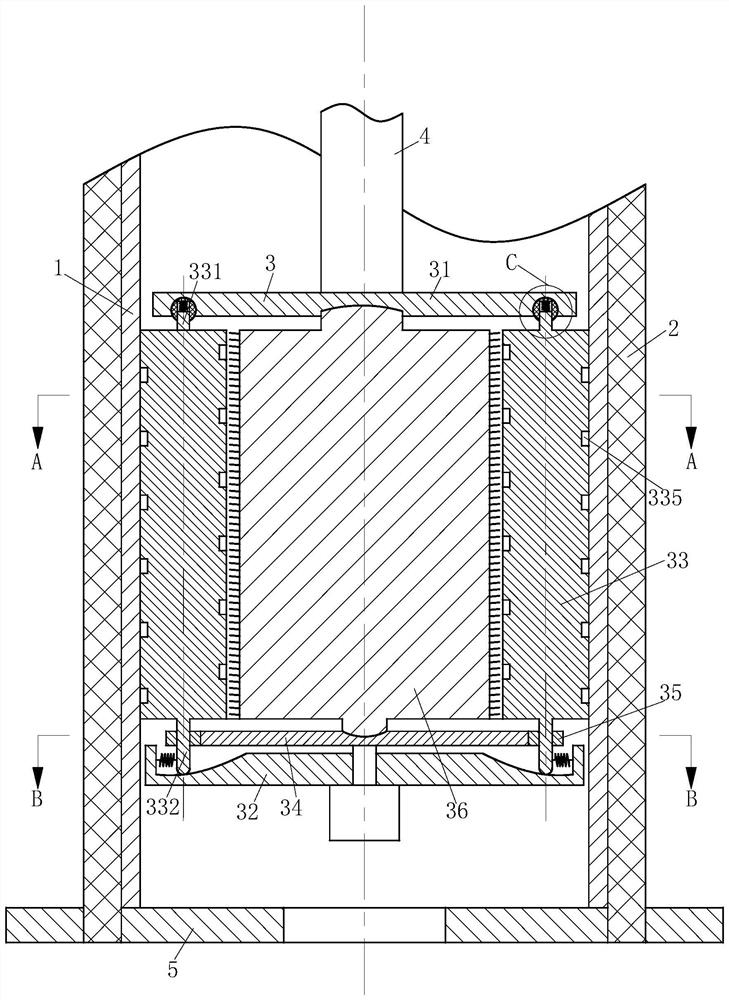

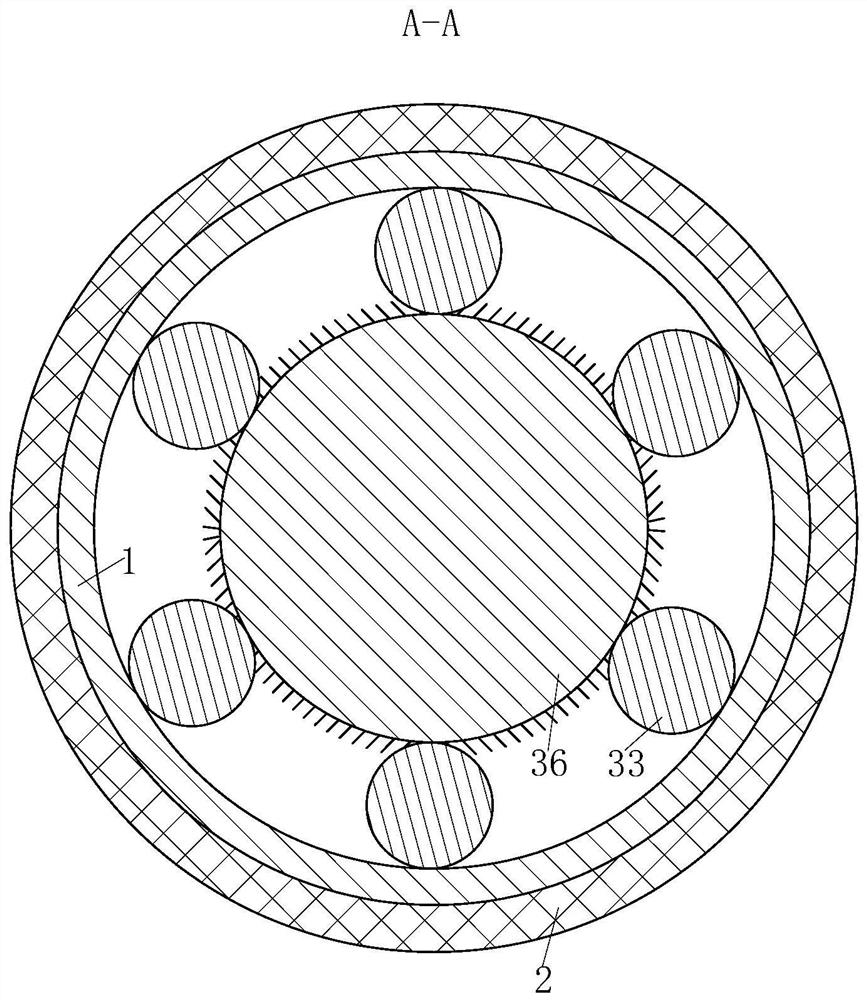

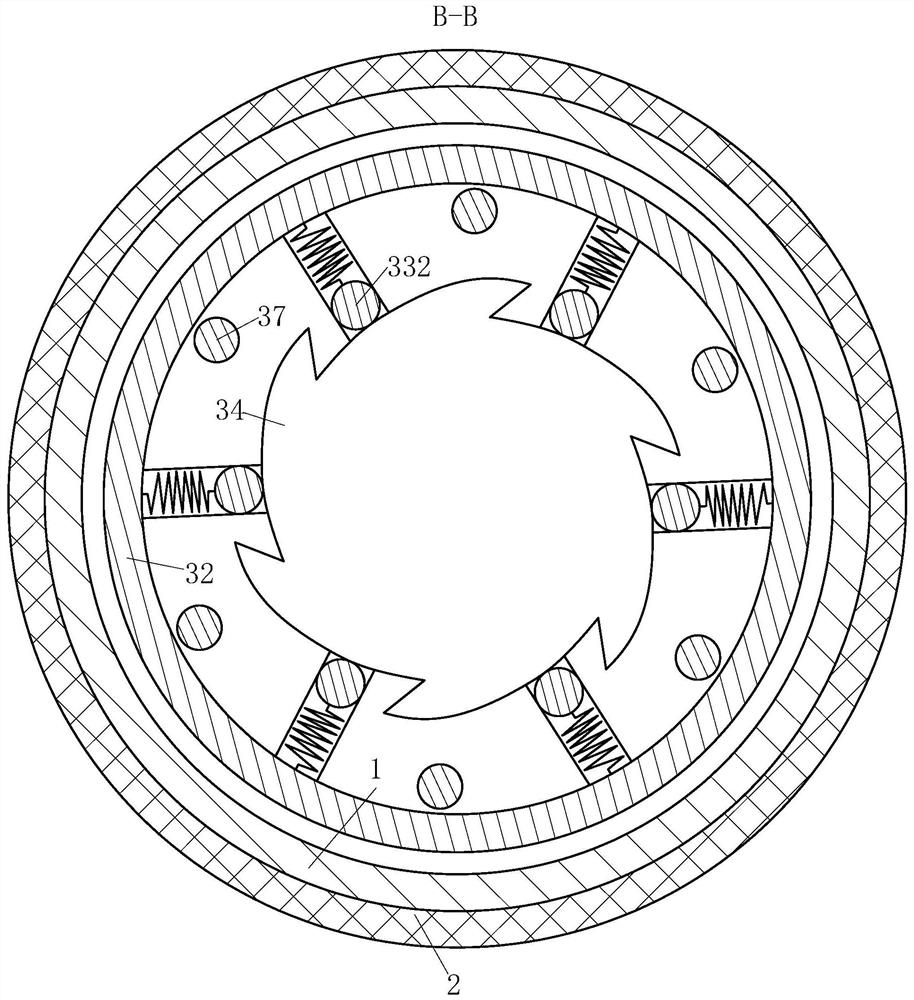

[0024] As an embodiment of the present invention, the end of the No. 1 protrusion 331 is provided with a spherical bearing 333, and the No. 1 protrusion 331 is connected to the spherical bearing 333; the No. 1 fixed plate 31 is evenly provided with six hemispherical grooves , the hemispherical groove and the spherical bearing bush 333 are hinged. The controller controls the motor to rotate, and the motor rotates to drive the toggle plate 34 to rotate. The second projection 332 slides along the arc surface on the second fixed plate 32 under the extrusion of the spring and the toggle of the toggle plate 34, and the roller 33 The No. 2 protrusion 332 at the lower end slides to drive the No. 1 protrusion 331 at the upper end of the roller 33 to rotate, and the No. 1 protrusion 331 rotates to drive the spherical bearing 333 to rotate in the hemispherical groove. The contact area between the spherical bearing 333 and the hemispherical groove increases, and the roller 33 is added The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com