A blanking device for h-shaped steel

A cutting and steel technology, applied in the field of machinery, can solve the problems of defective products, increased production costs, inconvenient cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

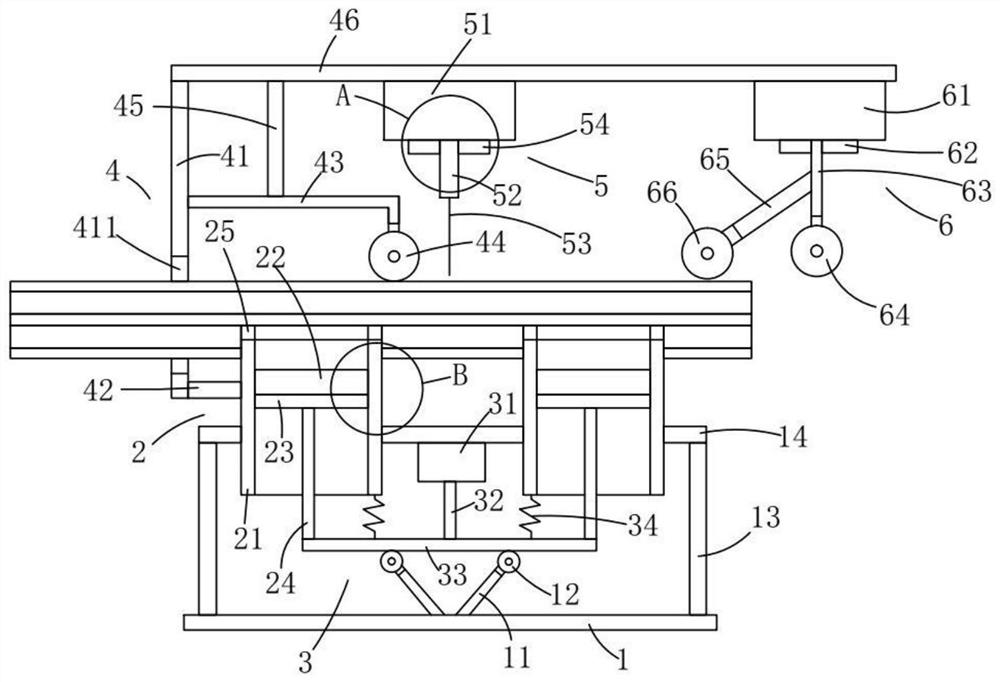

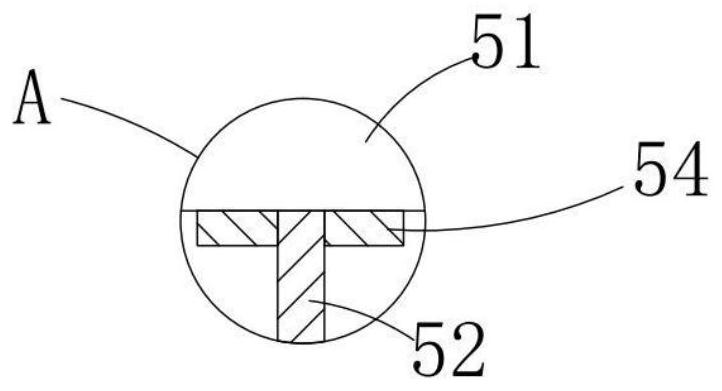

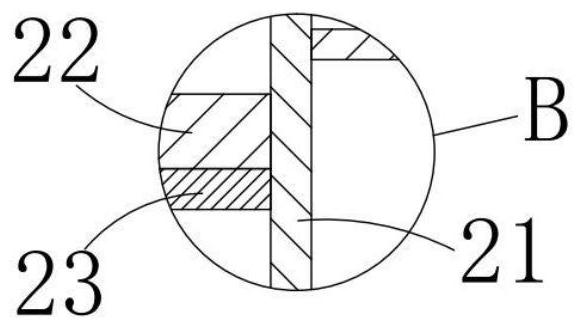

[0011] The blanking device for H-shaped steel materials of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0012] like Figure 1 to Figure 3 As shown, the blanking device for H-shaped steel in the present invention includes a bottom plate 1, a piston device 2 located on the left and right sides above the bottom plate 1, a drive device 3 arranged between the piston devices 2, and a drive device 3 arranged between the said bottom plate 1. The roller device 4 on the piston device 2 , the cutting device 5 and the pushing device 6 arranged on the roller device 4 .

[0013] like Figure 1 to Figure 3 As shown, the base plate 1 is a cuboid, and the base plate 1 is provided with first elastic rods 11 located on the left and right sides above it, a first roller 12 arranged on the upper end of the first elastic rod 11, and a first roller 12 located on the upper end of the first elastic rod 11. A supporting rod 13 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com