Riser wax mold and wax mold manufacturing device

A technology of wax molds and molds, which is applied in the field of mold forming, can solve the problems of disconnection and falling off of riser wax molds, and achieve the effect that it is not easy to break off and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

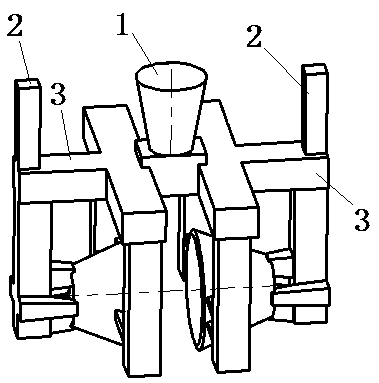

[0035] like figure 1 As shown, the group mold in the prior art includes a sprue cup wax mold 1, a riser wax mold 2 and a runner wax mold 3, the riser wax mold 2 and the sprue wax mold 3 are bonded and fixed, and the riser wax mold 2 It is a cuboid structure with a simple structure, and the long side of the cuboid structure extends in the up and down direction, so that the height of the inner cavity of the riser formed by the riser wax mold 2 is higher, thereby enhancing the feeding effect of the riser. The lower end surface area of the riser wax mold 2 of this structure is small, and the degree of firmness when it is fixed with the sprue wax mold 3 is relatively low. The situation that the whole pottery mold is scrapped due to disconnection and falling off from the runner wax mold 3 .

[0036]In order to solve the above-mentioned problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com