Bakelite cover adhesive for automatic generator

A technology for automotive generators and adhesives, applied in the types of adhesives, chitin adhesives, hyaluronic acid adhesives, etc., which can solve the problems of complex manufacturing process, high cost, and difficult repair of bonding places

Inactive Publication Date: 2011-04-13

张元元

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when it is applied to the car bakelite cover, there are the following defects: 1. The manufacturing process is complicated and the cost is high; 2. The use conditions of the car will lead to the gradual aging and failure of the bonded part; 3. It is not easy to repair when the bonded part breaks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

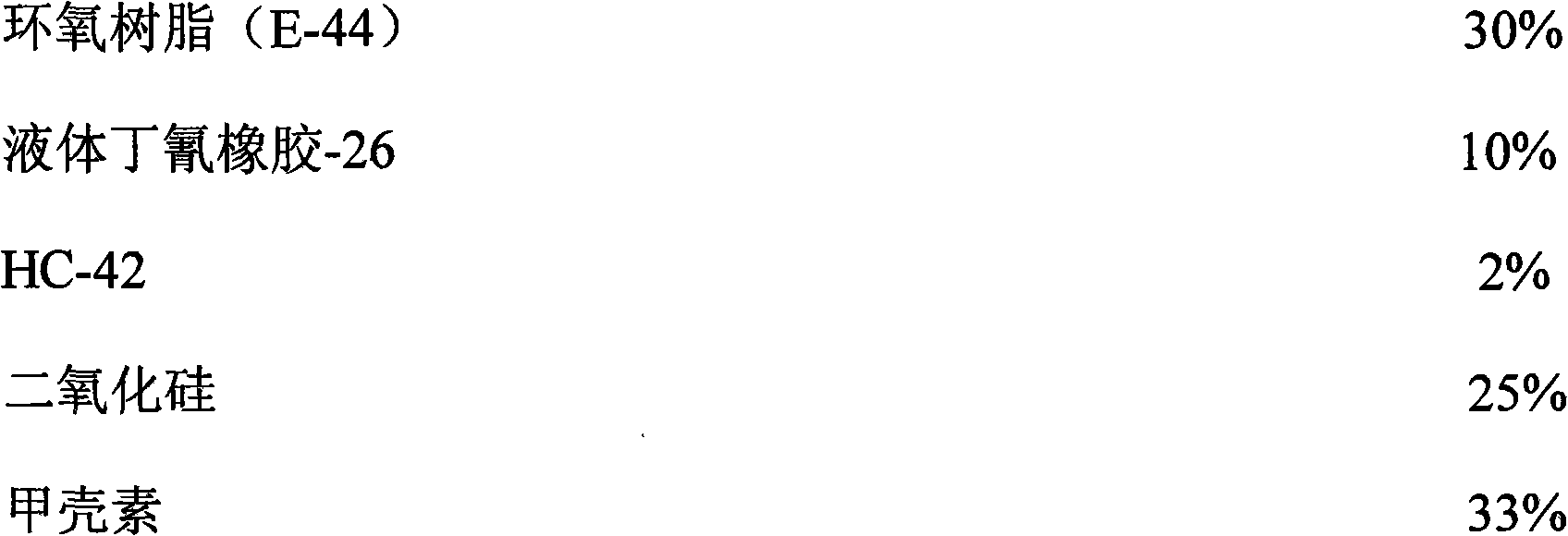

[0009] The following is an embodiment of it, and the parts by mass of each component are

[0010]

[0011] The production method is as follows: firstly mix epoxy resin (E-44) and liquid nitrile rubber-26 at 90°C, then mix the resultant with HC-42 and silica at 90°C, then add chitin and stir , cooled to room temperature.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a Bakelite cover adhesive for an automatic generator, which comprises the following components of epoxy resin (E-44), liquid acrylonitrile-butadiene rubber-26, HC-42, silica and chitin. The adhesive has the characteristics of firmness, difficult breaking and shedding, no release of materials harmful to a human body, environment protection and the like.

Description

technical field [0001] The invention belongs to the field of automobile manufacturing industry and provides a solid and environment-friendly adhesive for the bakelite cover of automobile generators. technical background [0002] With the rapid popularization of automobiles, people's requirements for auto parts are also getting higher and higher. The alternator of the automobile is the core part of the automobile, and the adhesive for the alternator bakelite cover plays a pivotal role. In view of this, many inventors have proposed various methods of making adhesives. [0003] For example, the Chinese patent "CN101230242 Polyvinyl Glyoxylic Acid Safety Adhesive Synthesis Method" provides a method of using non-toxic, odorless and non-volatile glyoxylic acid instead of formaldehyde to synthesize polyvinyl glyoxylic acid safety adhesives. For paper products, building materials and fiber bonding. Chinese patent "CN85105513 Phenolic Resin-Polyisocyanate Adhesive System" provides...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J163/00C09J109/02C09J105/08

Inventor 张元元

Owner 张元元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com