Copper foil pressing and slitting device for aluminum substrates and copper foil slitting method thereof

An aluminum substrate and copper foil technology, which is applied to the field of copper foil pressing and slitting devices for aluminum substrates, can solve problems such as inconvenience in the production of aluminum substrates, and achieve the effects of avoiding cutting skew and dimensional deviation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

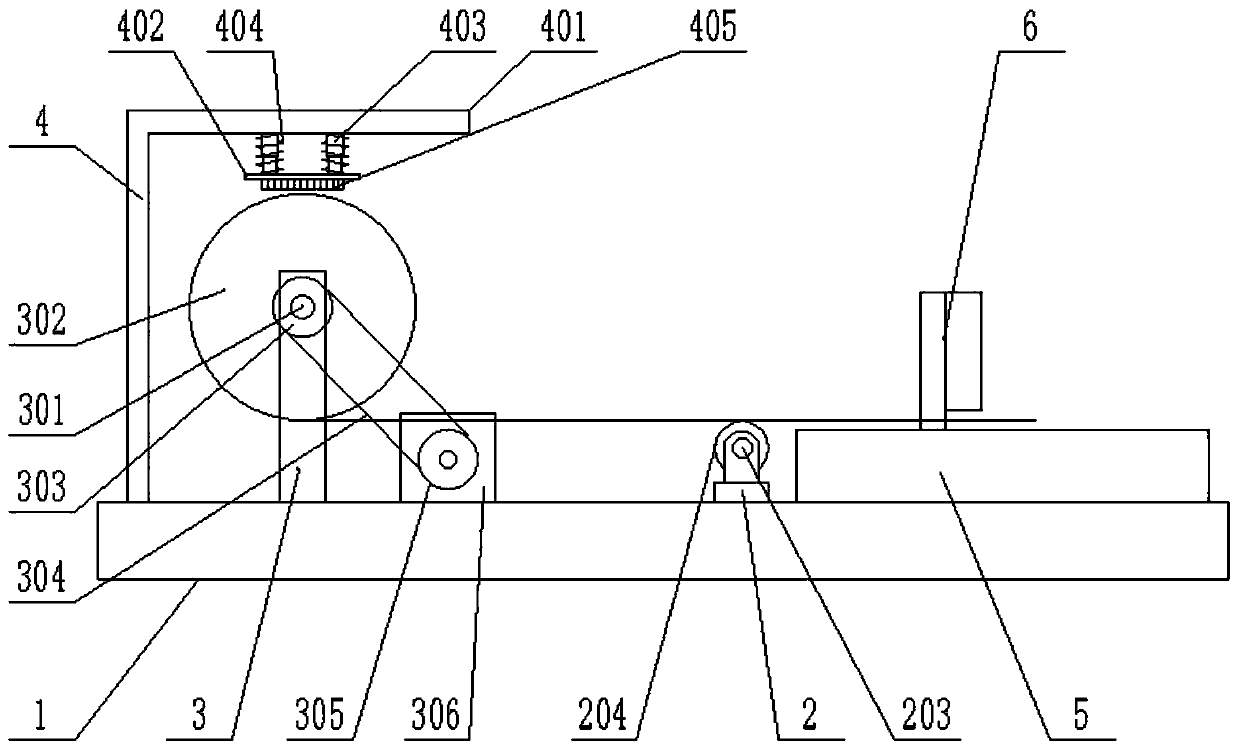

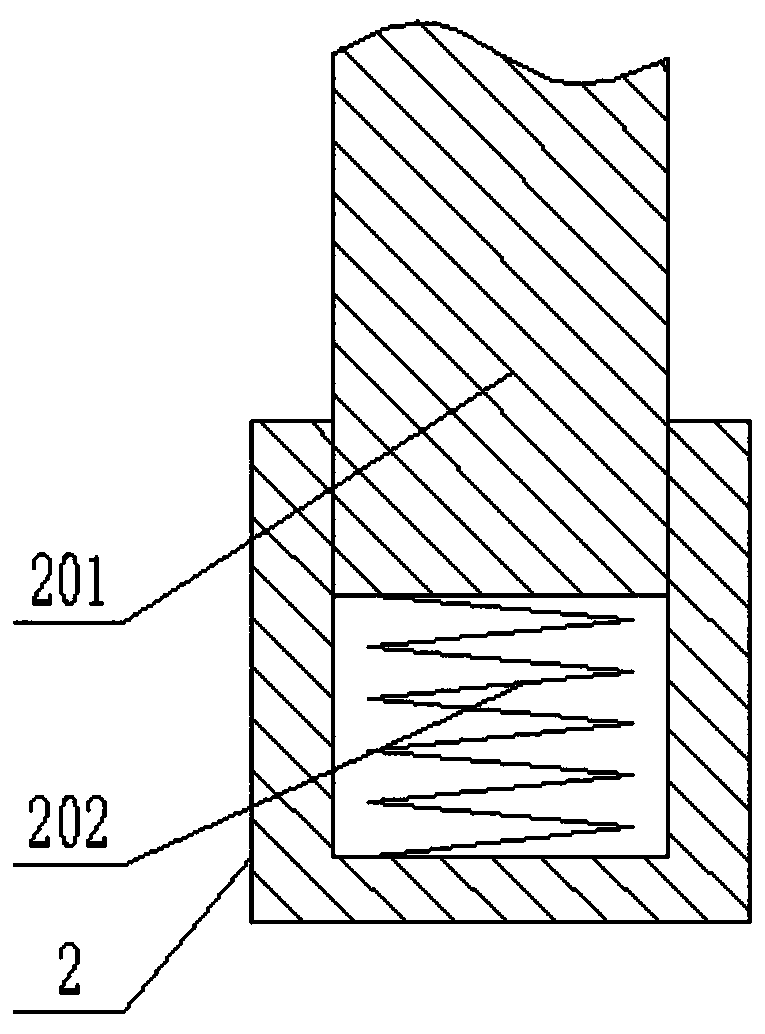

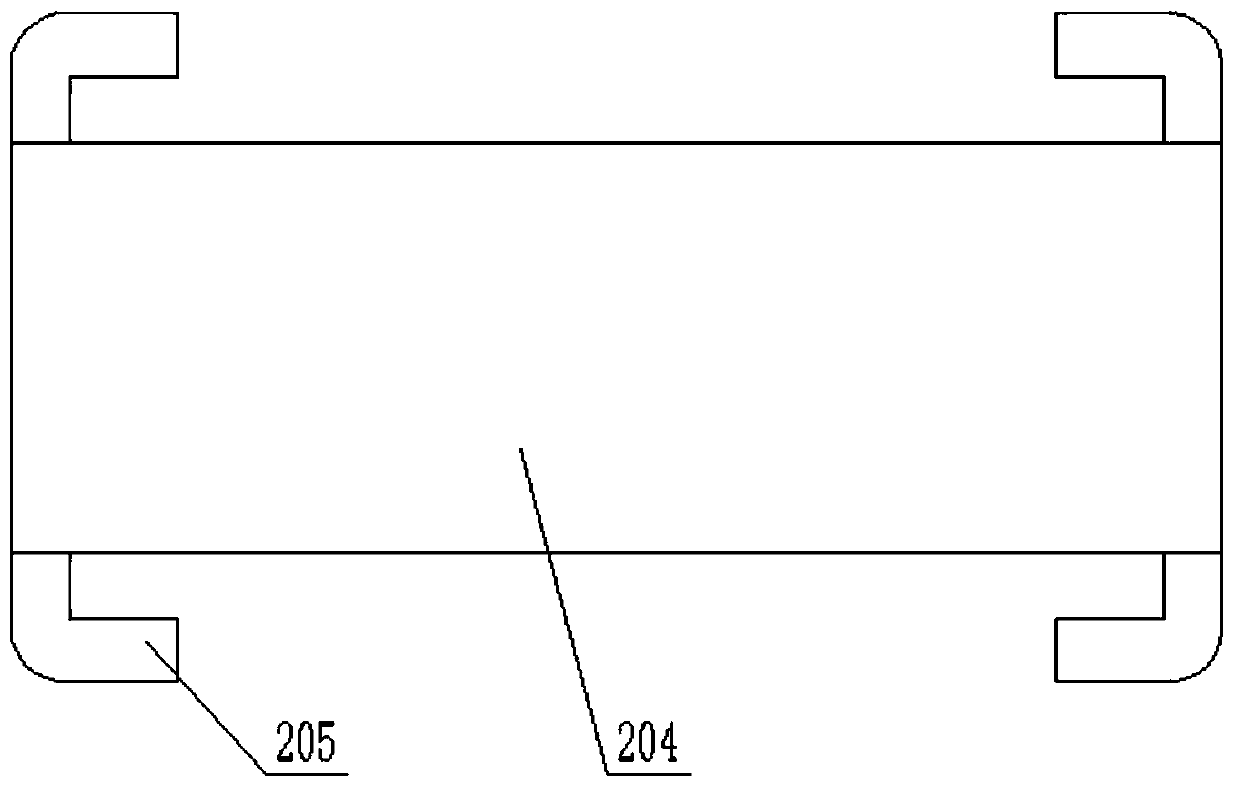

[0038] Example 1, please refer to Figure 1-5 , a copper foil pressing and cutting device for aluminum substrates, including a base 1, a sleeve 2, a mounting frame 3, a support frame 4 and a cutting platform 5, and the upper surface of the base 1 is fixedly connected with two front and rear ends on the right side. root sleeve 2, a lifting rod 201 is slidingly connected in the sleeve pipe 2, and the bottom surface of the lifting rod 201 is fixedly connected with the bottom surface of the sleeve pipe 2 through an adjustment spring 202; The first rotating shaft 203, the first rotating shaft 203 is fixedly connected with the guide roller 204, the two sides of the guide roller 204 are provided with guard plates 205, and the top of the guard plate 205 is bent inwardly;

[0039] The left side of the upper end of the base 1 is fixedly connected with a mounting frame 3, and the upper end of the mounting frame 3 is rotatably connected with a second rotating shaft 301, and the middle part ...

Embodiment 2

[0043] Example 2, please refer to Figure 1-5 And 6, a copper foil pressing and cutting device for aluminum substrates, including a base 1, a sleeve 2, a mounting frame 3, a support frame 4 and a cutting platform 5, and the front and rear ends on the right side of the upper surface of the base 1 are fixedly connected There are two casing pipes 2, and a lifting rod 201 is slidingly connected in the casing pipe 2, and the bottom surface of the lifting rod 201 and the bottom surface of the casing pipe 2 are fixedly connected by an adjustment spring 202; the lifting rods 201 on the front and rear sides rotate A first rotating shaft 203 is installed, and a guide roller 204 is fixedly connected to the first rotating shaft 203. Guard plates 205 are arranged on both sides of the guide roller 204, and the top of the guard plate 205 is bent inwardly;

[0044] The left side of the upper end of the base 1 is fixedly connected with a mounting frame 3, and the upper end of the mounting fram...

Embodiment 3

[0049] Embodiment three, please refer to Figure 1-9 , a copper foil pressing and cutting device for aluminum substrates, including a base 1, a sleeve 2, a mounting frame 3, a support frame 4 and a cutting platform 5, and the upper surface of the base 1 is fixedly connected with two front and rear ends on the right side. root sleeve 2, a lifting rod 201 is slidingly connected in the sleeve pipe 2, and the bottom surface of the lifting rod 201 is fixedly connected with the bottom surface of the sleeve pipe 2 through an adjustment spring 202; The first rotating shaft 203, the first rotating shaft 203 is fixedly connected with the guide roller 204, the two sides of the guide roller 204 are provided with guard plates 205, and the top of the guard plate 205 is bent inwardly;

[0050] The left side of the upper end of the base 1 is fixedly connected with a mounting frame 3, and the upper end of the mounting frame 3 is rotatably connected with a second rotating shaft 301, and the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com