Double-layer shell titanium alloy deflector shroud acoustic three-dimensional control method

A three-dimensional control, double hull technology, applied in the directions of hydrodynamic characteristics/hydrostatic characteristics, hull, ship parts, etc., can solve the problems of difficult self-noise control, difficult to ensure sound transmission effect, etc., to achieve compact structure , The effect of excellent sound transmission performance and effective control of self-noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

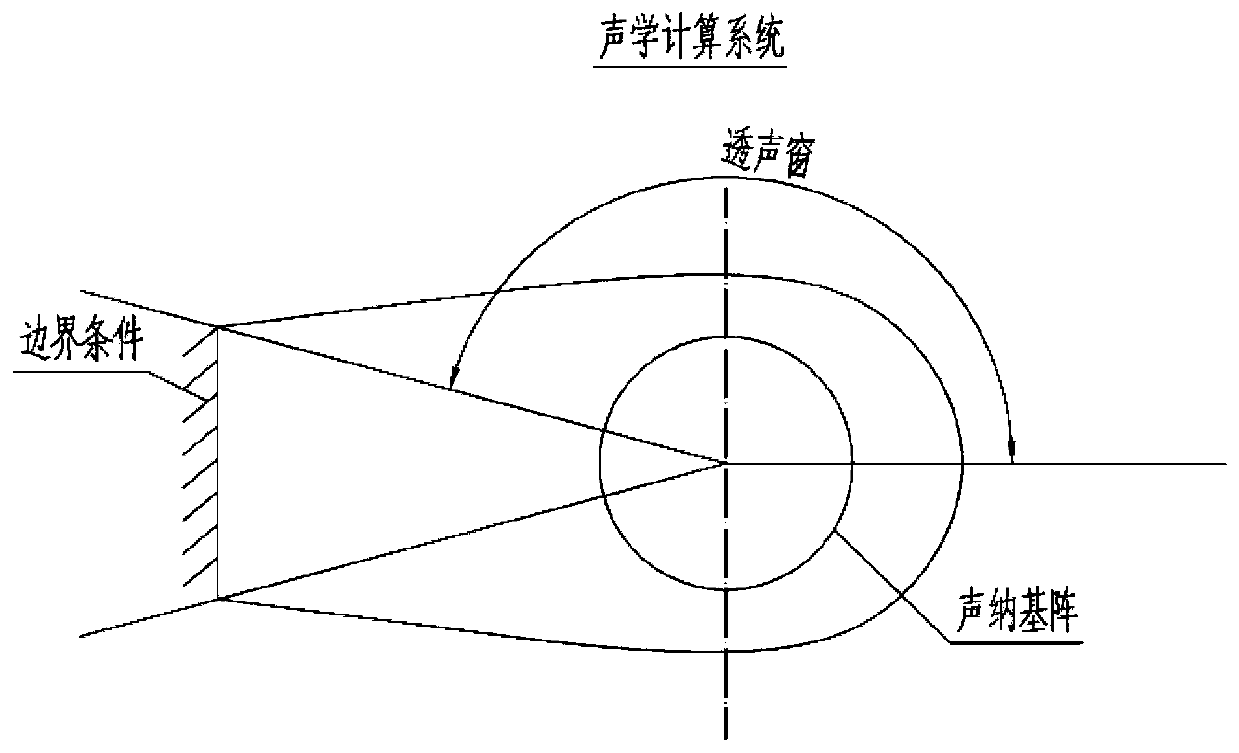

[0039] Under the premise that the headline shape of the bulbous nose is determined, follow steps 1 to 4 and carry out gradually. First determine the three-dimensional range of the sound-transmitting window, then carry out structural layout and calculation verification, the third step is the acoustic simulation calculation, and the fourth step is the self-noise control design.

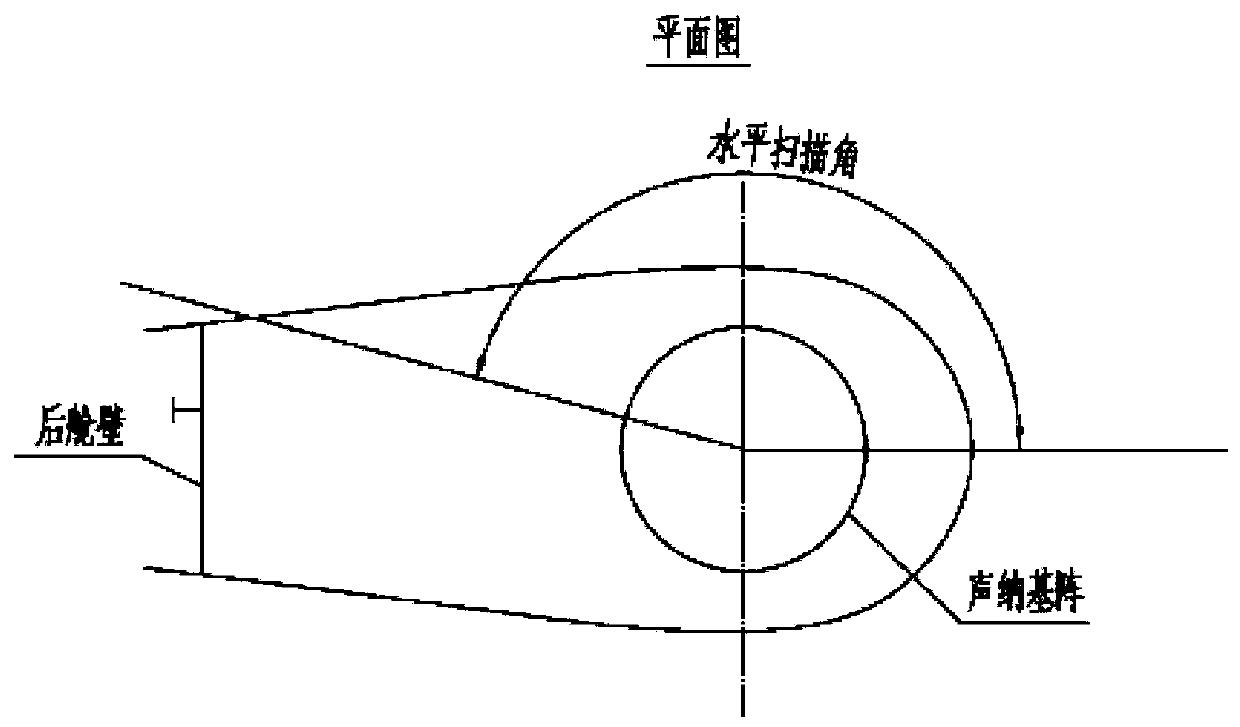

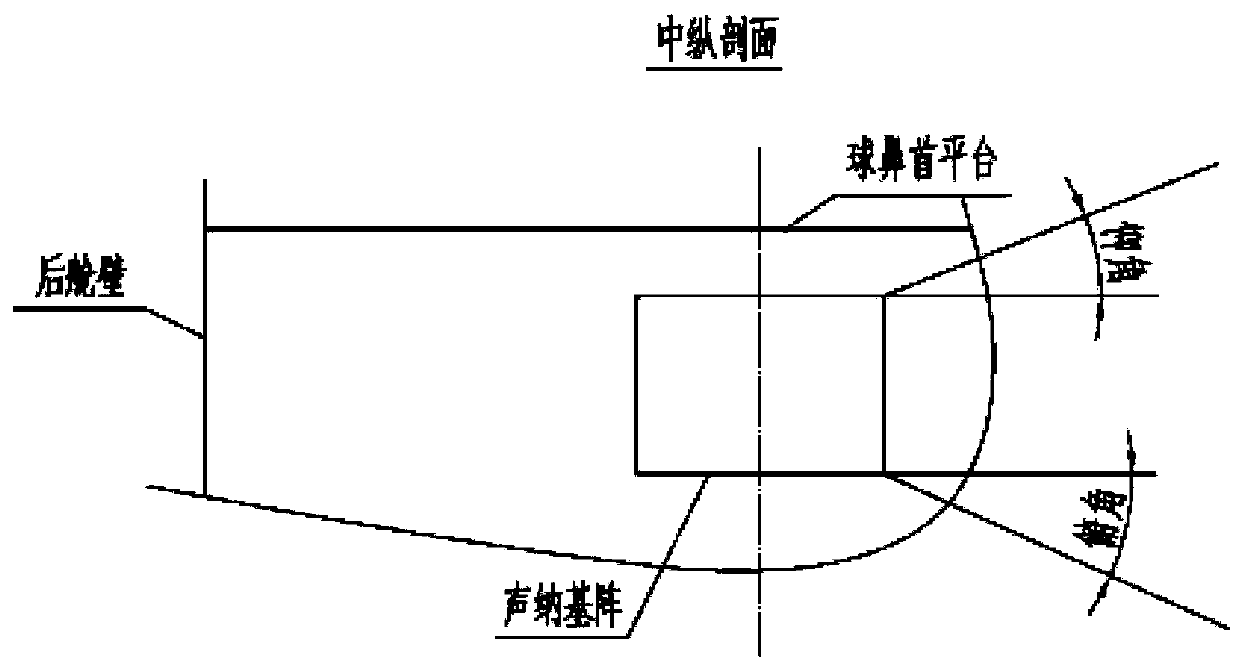

[0040] 1 According to the horizontal scanning angle a°, determine the maximum sound transmission window as a+2°, the vertical elevation angle as b°, and the depression angle as c°, determine the minimum vertical range of the sound transmission window as b+1°, and the depression angle as c+2° , according to the installation elements of the array, at the same time, it is determined that the rear bulkhead is #d rib position, and the sonar installation platform is e mm on the baseline.

[0041] 2 Determine the size of the rear bulkhead frame to be 6*240 / 8*80, the size of the sonar installation platform to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com