Conveying system of optical fiber disk

A technology of conveying system and optical fiber disk, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of instability, heavy work tasks, unsafety, etc., and achieve the effect of equal power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

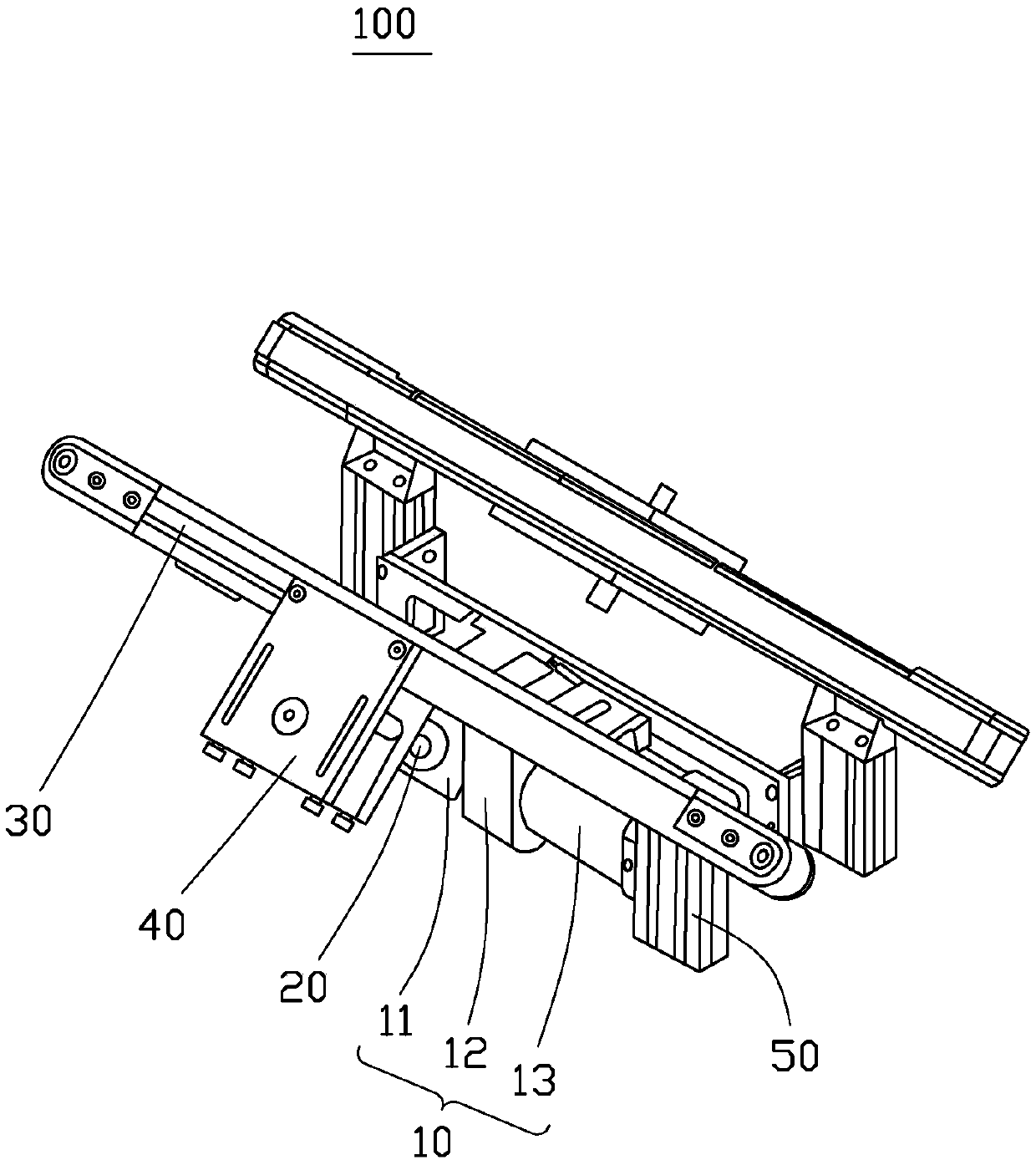

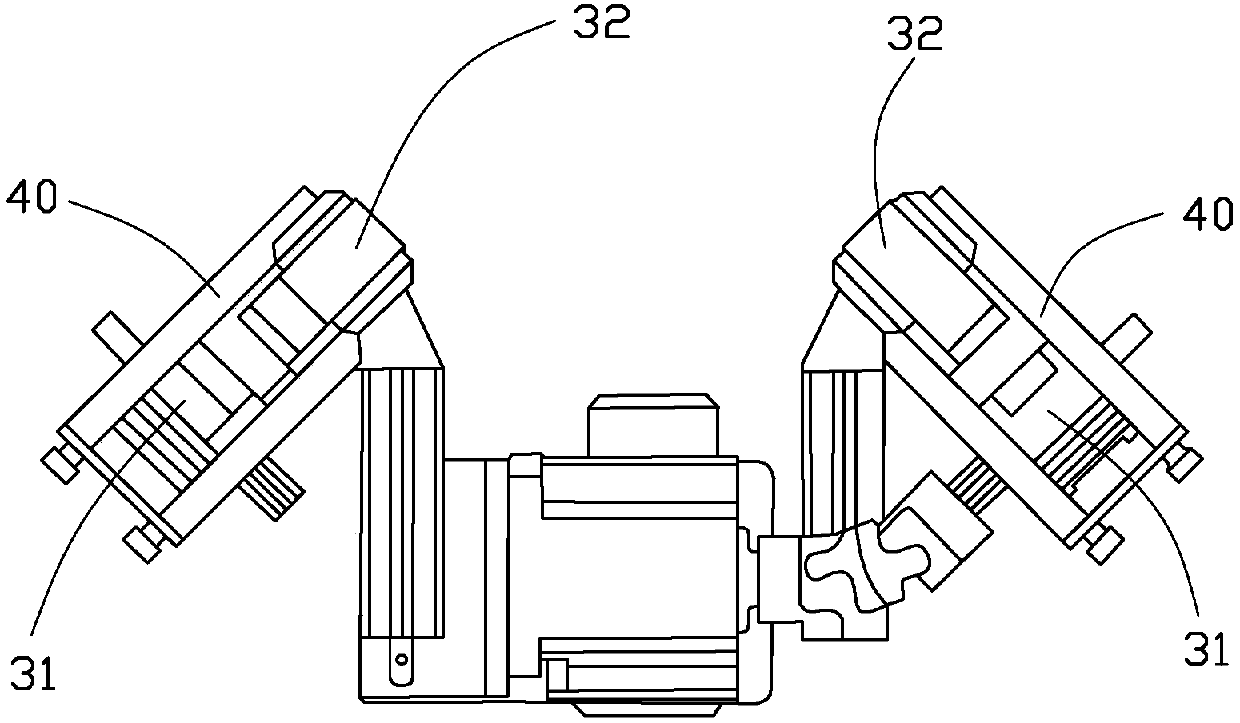

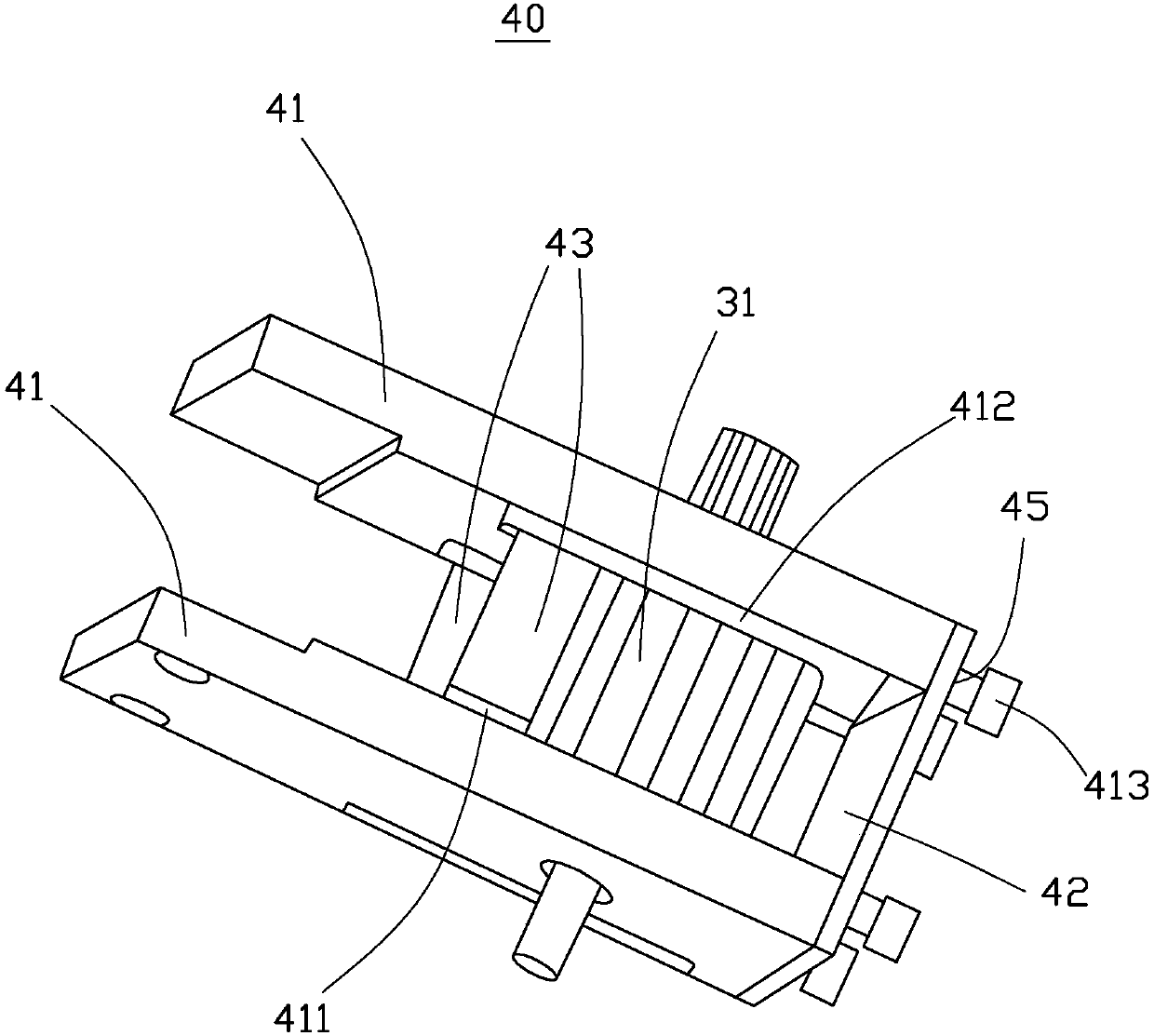

[0019] see figure 1 with figure 2 , an embodiment of the present invention provides a transport system 100 for an optical fiber tray, which mainly includes a power device 10 , a connector 20 , a conveyor belt device 30 , a tensioning mechanism 40 and a bracket 50 . The conveyor belt device 30 includes a synchronous toothed pulley 31 fixedly installed at both ends of the support 50 , and two synchronous toothed belts 32 moving on the synchronous toothed pulley 31 .

[0020] The power unit 10 includes an electric motor 13 , a reducer 12 and a steering gear 11 , the output shaft of the electric motor 13 is connected with the main shaft of the reducer 12 to increase the output torque of the electric motor 13 . One end of the steering gear 11 is connected to the output shaft of the speed reducer 12, and is used to convert the input torque into two synchronously rotating outputs to ensure the synchronous rotation of the two output shafts; the other end of the steering gear 11 pass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap