Push-to-pop detergent box and washing machine

A detergent box and water box technology, applied in the field of washing machines, can solve problems such as slowing down the production rhythm of washing machines, and achieve the effects of simplifying production complexity, speeding up production rate, and achieving remarkable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

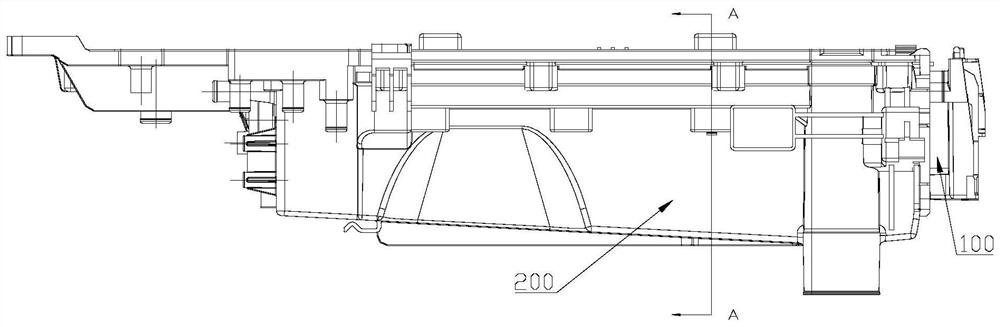

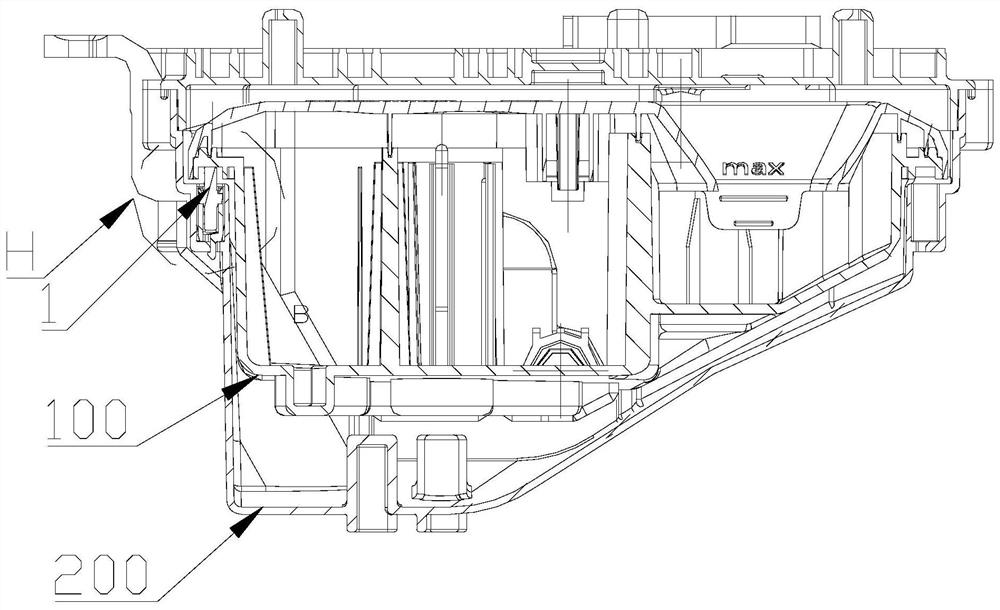

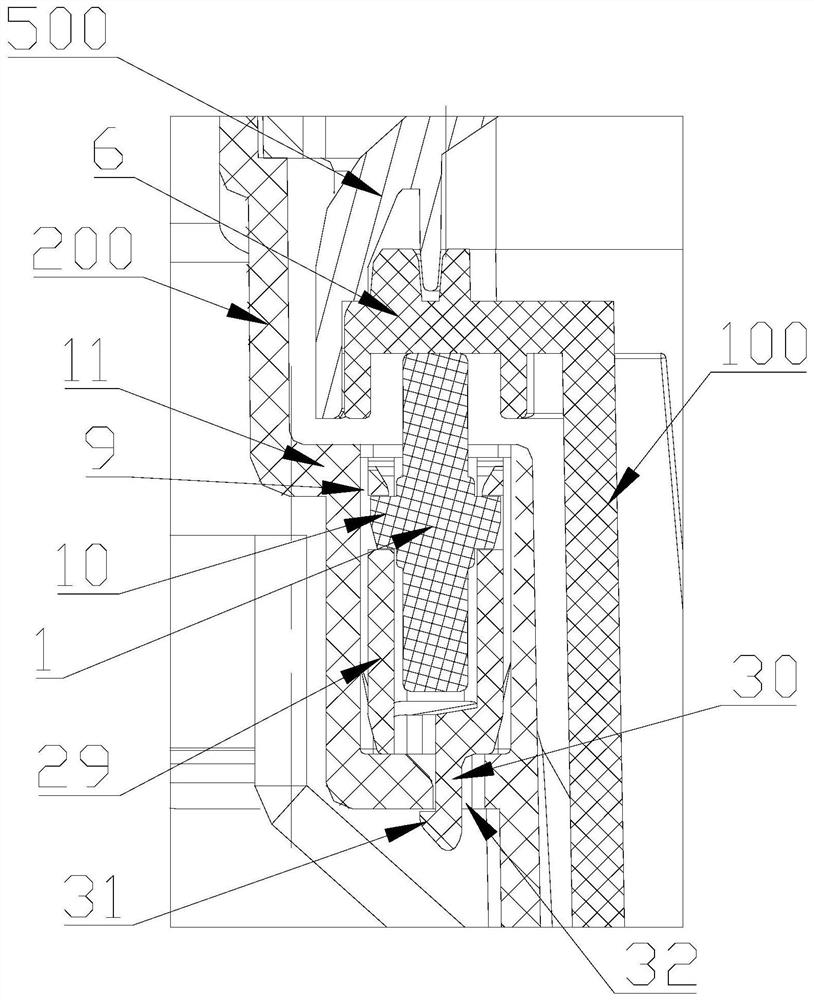

[0039] Such as Figure 1 to Figure 5As shown, in this embodiment, a push-to-play detergent box is introduced, including a water box 200 installed on the washing machine casing 300, and a pull-out and push-in detergent box 100 is installed in the water box 200; A slide rail structure is provided between the water box 200 and the detergent box 100, and the slide rail structure includes a plurality of pulley assemblies in contact with the detergent box 100, so as to reduce the friction during the pulling and pushing process of the detergent box 100.

[0040] By correspondingly clamping the pulley into the installation groove set on the water box through the installation shell, the pulley assembly integrates the housing for the installation of the rotating shaft, avoiding the need to add installation holes to the water box installation groove, and simplifying the installation of the water box Production complexity; In addition, the pulley is inserted into the installation groove p...

Embodiment 2

[0052] Such as figure 1 and Figure 4 to Figure 7 As shown, this embodiment introduces a push-to-play detergent box, including a water box installed on the shell of the washing machine, and a pull-out and push-in detergent box 100 is installed in the water box 200; At least one pulley assembly is installed on the agent box 100, and the installation shell 29 of the pulley assembly is fixedly installed with the detergent box 100. The pulley 1 that can rotate around the shaft is installed in the installation shell 29, and a part of the wheel surface of the pulley 1 passes through the opening for installation. The shell 29 is in position-limited contact with the water box 200 to reduce friction in the process of pulling out and pushing in the detergent box 100 .

[0053] By correspondingly clamping the pulley into the installation groove provided on the detergent box through the installation shell, the pulley assembly integrates the housing for the installation of the rotating sh...

Embodiment 3

[0061] In this embodiment, a kind of push-type detergent box is introduced, which includes a water box 200 installed on the shell of the washing machine, and a pull-out and push-in detergent box 100 is installed in the water box 200; the water box 100 The top wall of the top wall is provided with a plurality of inverted installation grooves 9, and a corresponding pulley assembly is installed in each installation groove 9, and the lower part of the pulley 1 installed on each pulley assembly passes through the opening of the installation shell 29, and the pulley of the part passes through 1 wheel surface and detergent box 100 top wall phase limit conflicts.

[0062] A plurality of limit pulleys are arranged between the upper cover of the detergent box and the top wall of the water box to avoid direct contact between the upper cover of the detergent box and the top wall of the water box, so that the limit pulleys are aligned during the pushing and pulling of the detergent box. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com