Steam turbine low-pressure through-flow area safety monitoring and prewarning system and working method

A technology of safety monitoring and early warning system, applied in safety devices, mechanical equipment, engine components, etc., to achieve the effect of improving safety and stability and improving the safety and economy of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

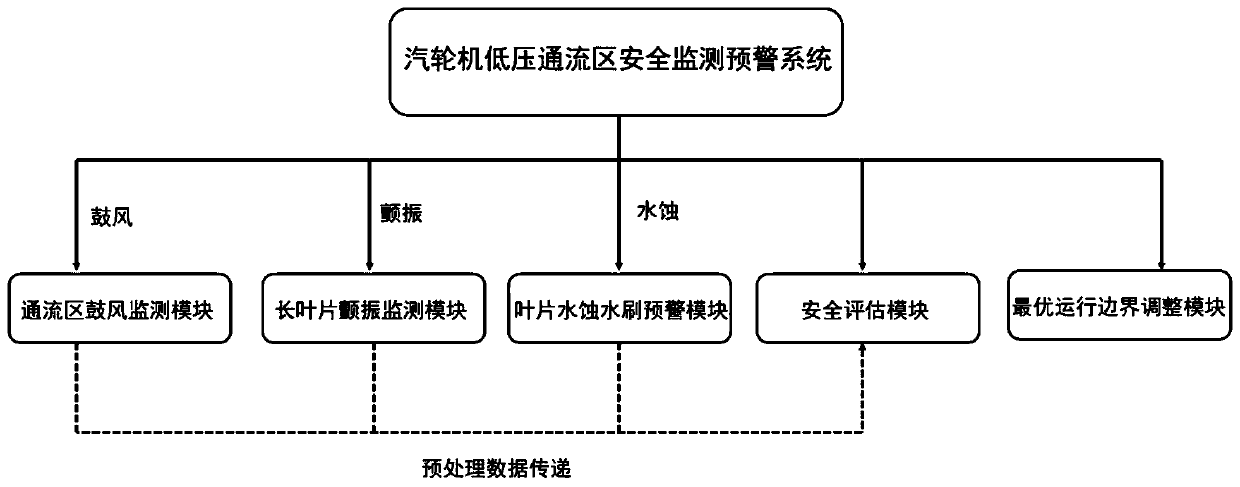

[0040] see figure 1 , the invention includes a blast monitoring module in the flow area, a long blade flutter monitoring module, a blade water erosion and brush early warning module, a safety assessment module and an optimal operation boundary adjustment module.

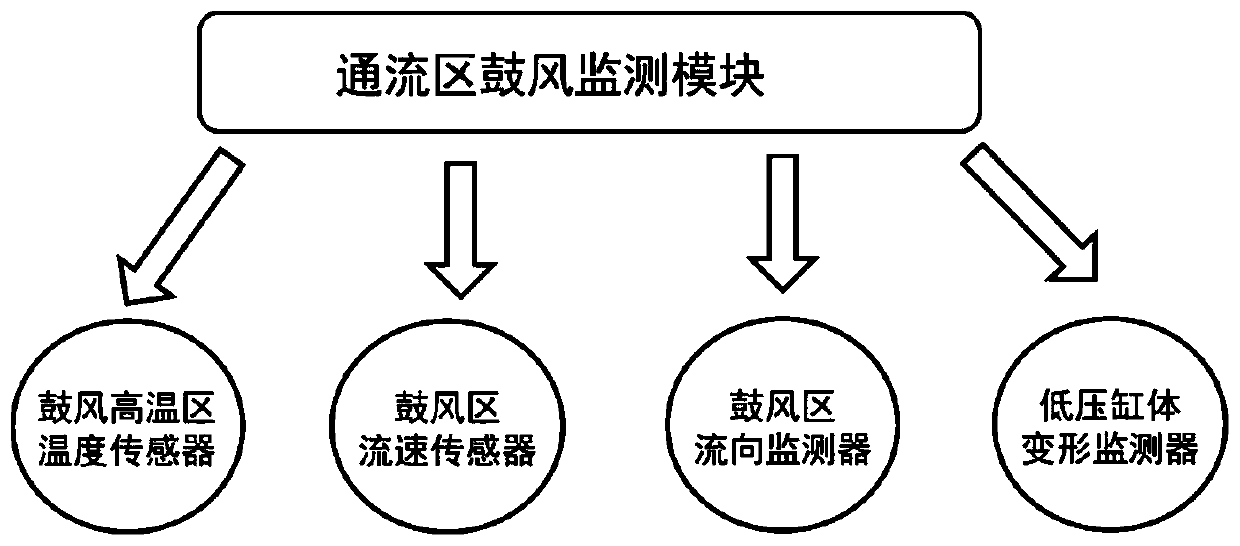

[0041] see figure 2 , the blower monitoring module in the through-flow area is used to evaluate and monitor the blast flow state in the low-pressure through-flow area and give quantitative characterization of key physical quantities. Specifically, it includes a temperature sensor in the high temperature zone of the blast, a flow rate sensor in the blast zone, a flow direction monitor in the blast zone, and a deformation monitor for the low pressure cylinder.

[0042] The temperature sensor in the blast high-temperature area should be placed in the area with the highest temperature field of the long blade b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com