A pilot valve fixing structure and a four-way reversing valve

A fixed structure and pilot valve technology, applied in the direction of fixing devices, valve devices, mechanical equipment, etc., can solve the problems of asynchronous vibration between the support cover and the support, affecting the performance of the valve, and reducing the resonance frequency, so as to avoid capillary breakage and prolong The effect of improving service life and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

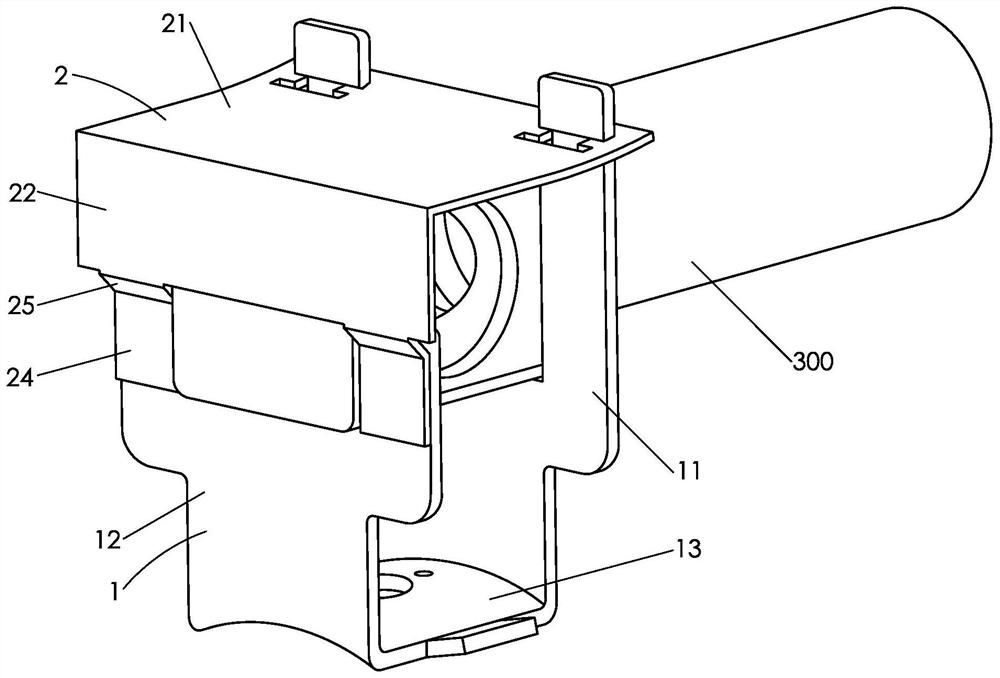

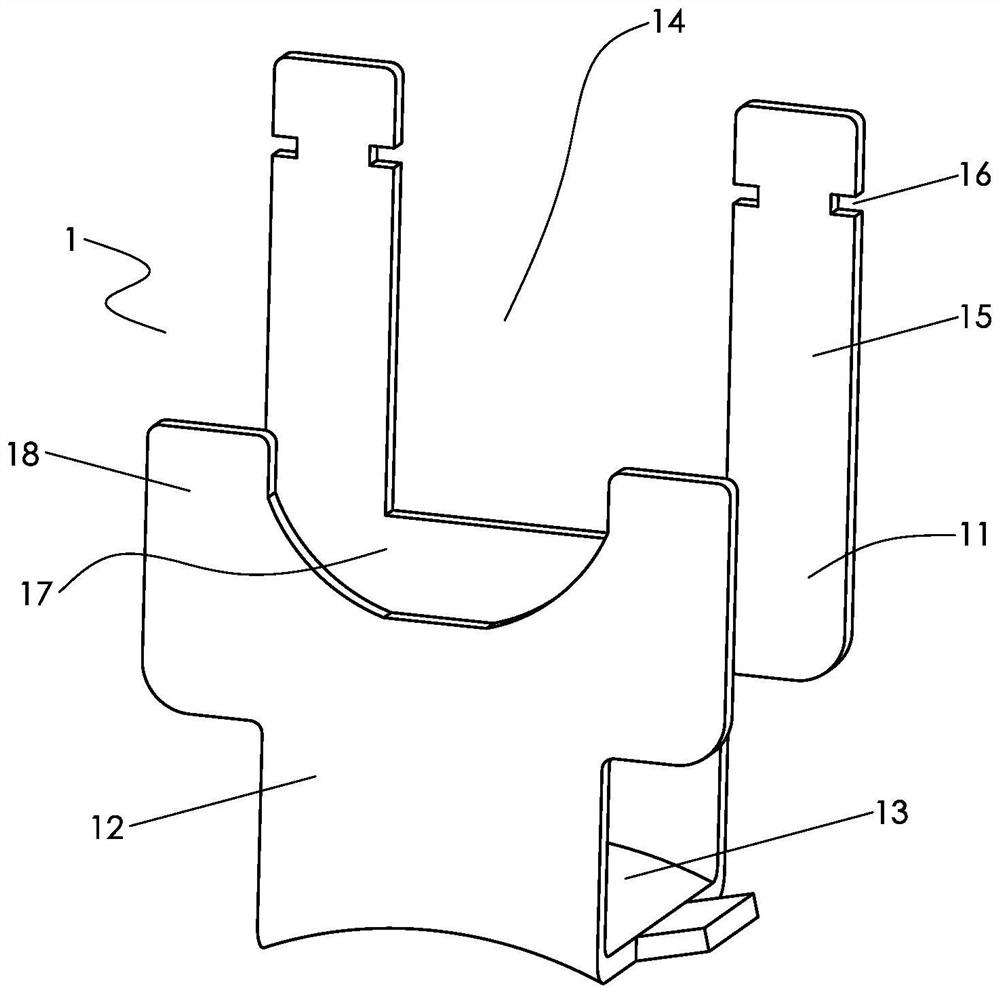

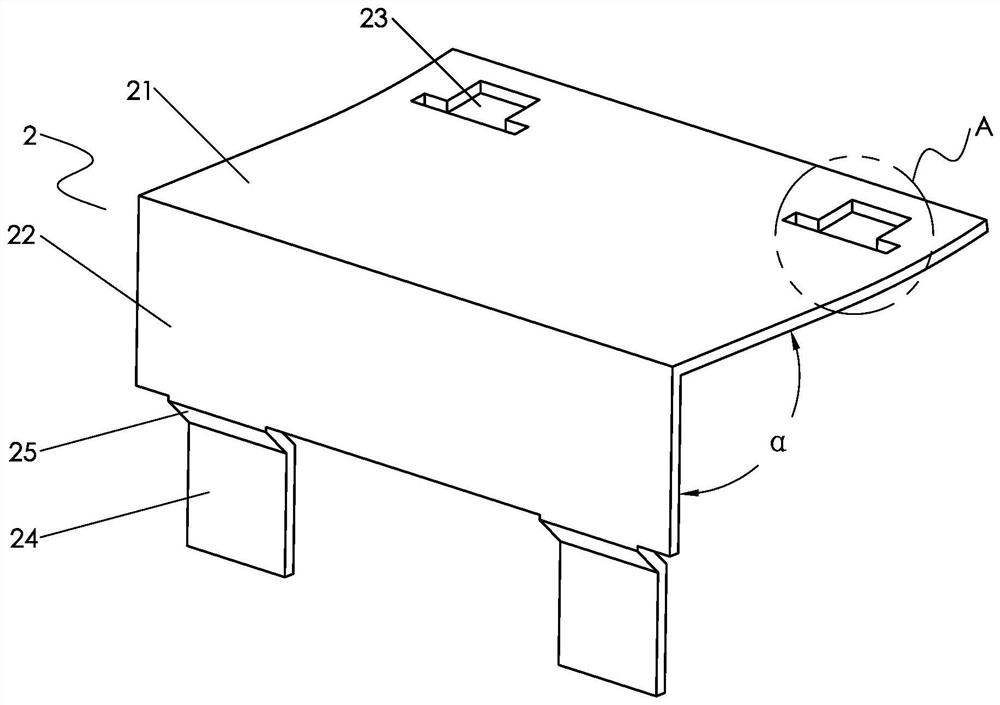

[0032] Such as figure 1 , figure 2 , image 3 As shown, the pilot valve fixing structure provided by Embodiment 1 of the present invention includes a bracket 1 and a support cover 2 that cooperate with each other to fix the pilot valve 300 . The bracket 1 includes a connecting plate 13 , a first supporting plate 11 and a second supporting plate 12 , and the first supporting plate 11 and the second supporting plate 12 are respectively arranged on opposite sides of the connecting plate 13 and arranged in parallel. The support cover 2 includes a cover plate 21 and a sealing plate 22 formed by bending one side of the cover plate. The cover plate 21 is fixedly connected to the first support plate 11 , the cover plate 22 is fixedly connected to the second support plate 12 , and one end of the pilot valve 300 is arranged between the bracket 1 and the support cover 2 to realize fixing.

[0033] After the installation is completed, the support 1 , the support cover 2 and the pilot ...

Embodiment 2

[0047] Such as Figure 6 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 above is that the sealing plate 22 is provided with a larger lug 24 at the end away from the cover plate 21, and the lug is directly attached to the second supporting plate. 12, and realize the fixed connection between the lug 24 and the second support plate 12 by welding, so as to realize the fixed connection between the sealing plate 22 and the second support plate 12.

[0048] Other structures of Embodiment 2 of the present invention are the same as those described in Embodiment 1 above, so details will not be repeated here.

[0049] It can be understood that, in this embodiment, the fixing between the lug 24 and the second support plate 12 can also be realized by means of screw connection, riveting and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com