A Parametric Modeling Method of Finite Element Mesh of Projectile with High Energy Beam Machining Rhombus Pattern

A grid parameterization, high-energy beam technology, applied in 3D modeling, image data processing, design optimization/simulation, etc., can solve problems such as cumbersome steps, cumbersome, complex geometry of projectile diamond grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and examples.

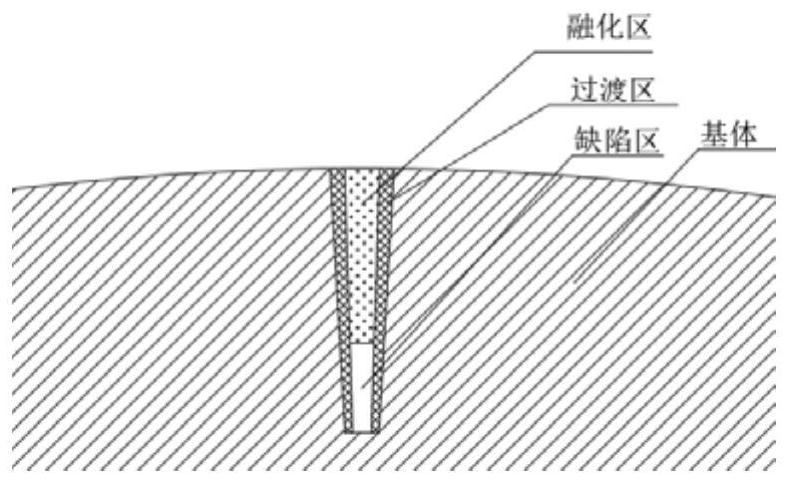

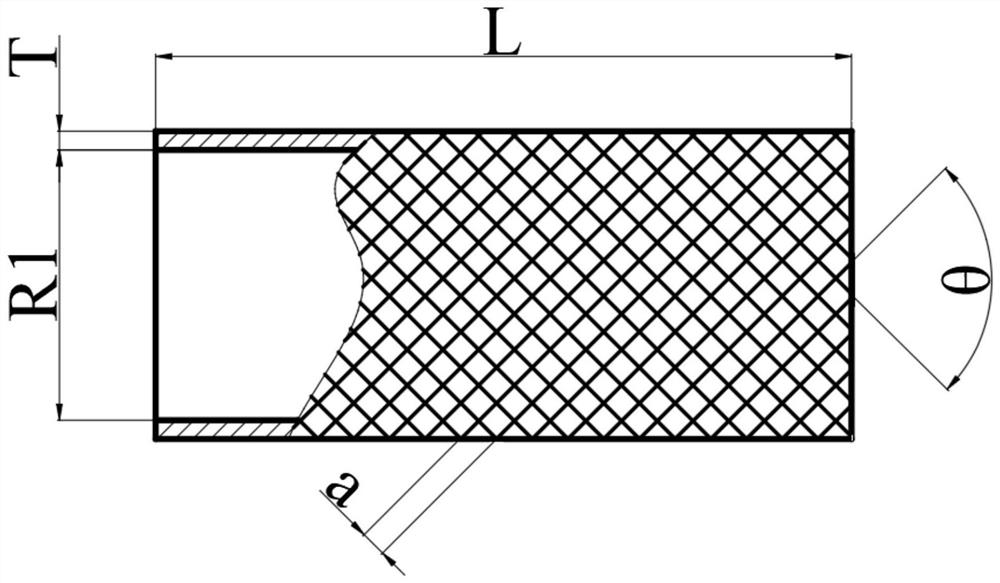

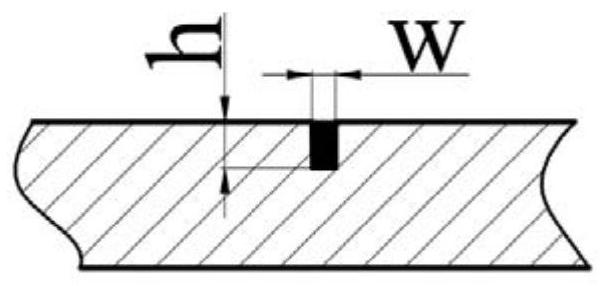

[0046] The invention provides a parametric modeling method of projectile finite element grid for high-energy beam processing rhombic pattern, which utilizes nodes to construct rhombic hexahedral mesh for projectile mesh division including high-energy beam groove lines, and completes projectile mesh Then, according to the proportional relationship between the high-energy beam groove line and the radial and circumferential directions of the projectile, the number of units in the high-energy beam groove line defect area is determined, and the number of units in the high-energy beam groove line defect area is deleted along the circumferential and radial directions respectively. The domain mesh completes the modeling, such as Figure 10 , Figure 11 and Figure 12 As shown, it specifically includes the following steps:

[0047] Step 1. Summarize the geometri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com