Wear-resistant metal material

A wear-resistant metal and aluminum profile technology, applied in the field of wear-resistant metal materials, can solve the problems of large power loss and many failures, and achieve the effects of small power loss, ingenious and novel ideas, and reasonable and practical structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

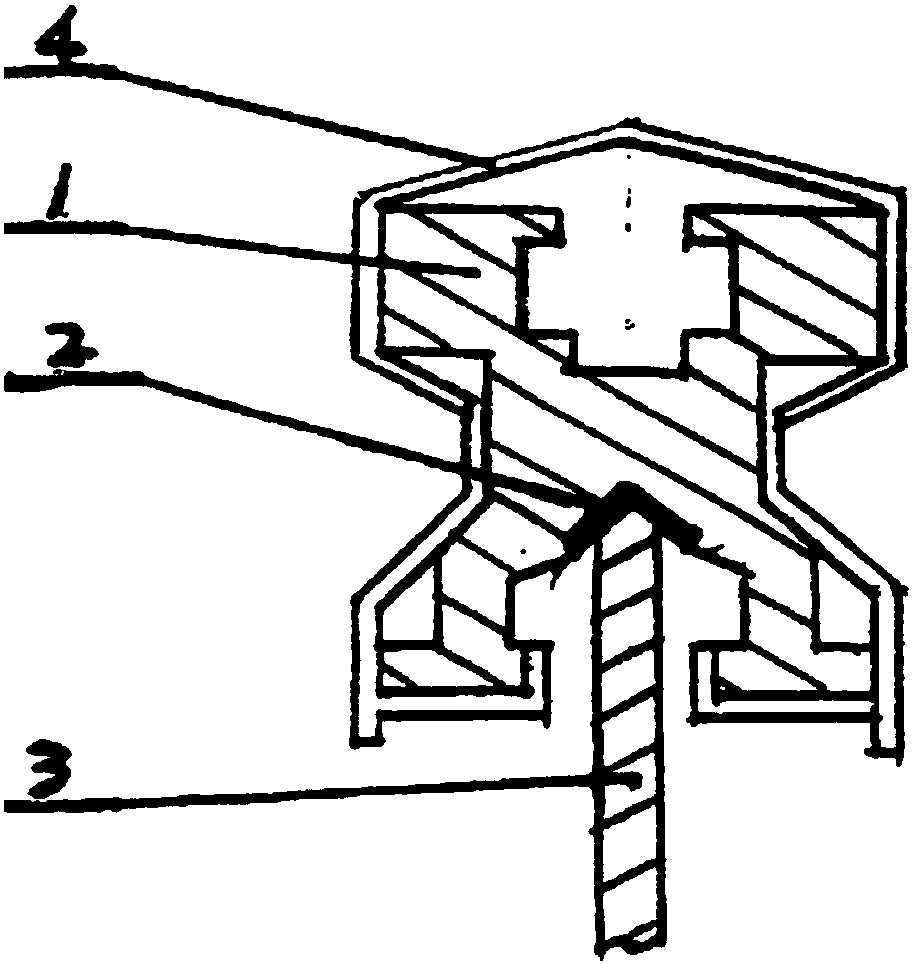

[0008] see figure 1 , the present invention includes an aluminum profile conductor 1 and a wear-resistant metal material 2 embedded in the aluminum profile conductor 1 , the wear-resistant metal material 2 is in contact with a conductive block 3 , and an insulating sheath 4 is sheathed outside the aluminum profile conductor 1 .

[0009] The aluminum profile conductor 1 of the present invention is shaped like an H and is drawn from an aluminum alloy. The aluminum profile conductor 1 is inlaid with a wear-resistant metal material 2, which is high-strength, nickel stainless steel. For the purpose of close contact and sliding, the aluminum section conductor 1 is sheathed in an insulating sheath 4 matching its shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com