Integrated intelligent combination box-type substation

A combination box and substation technology, applied in distribution substations, substation/distribution device casings, circuits, etc., can solve the problems of not preventing mice, unable to meet short-term rapid pressure relief, and excellent cable strength, and achieve high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

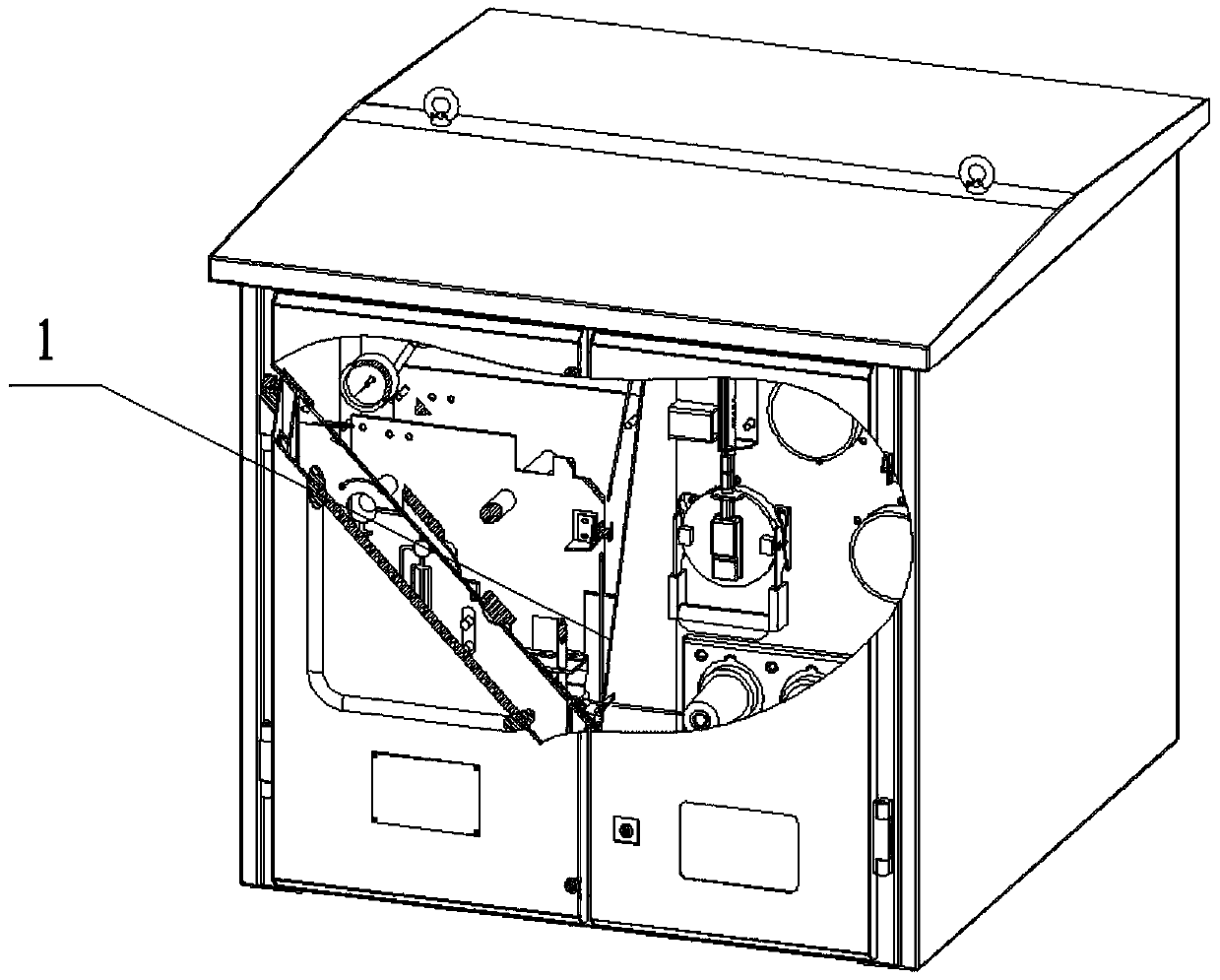

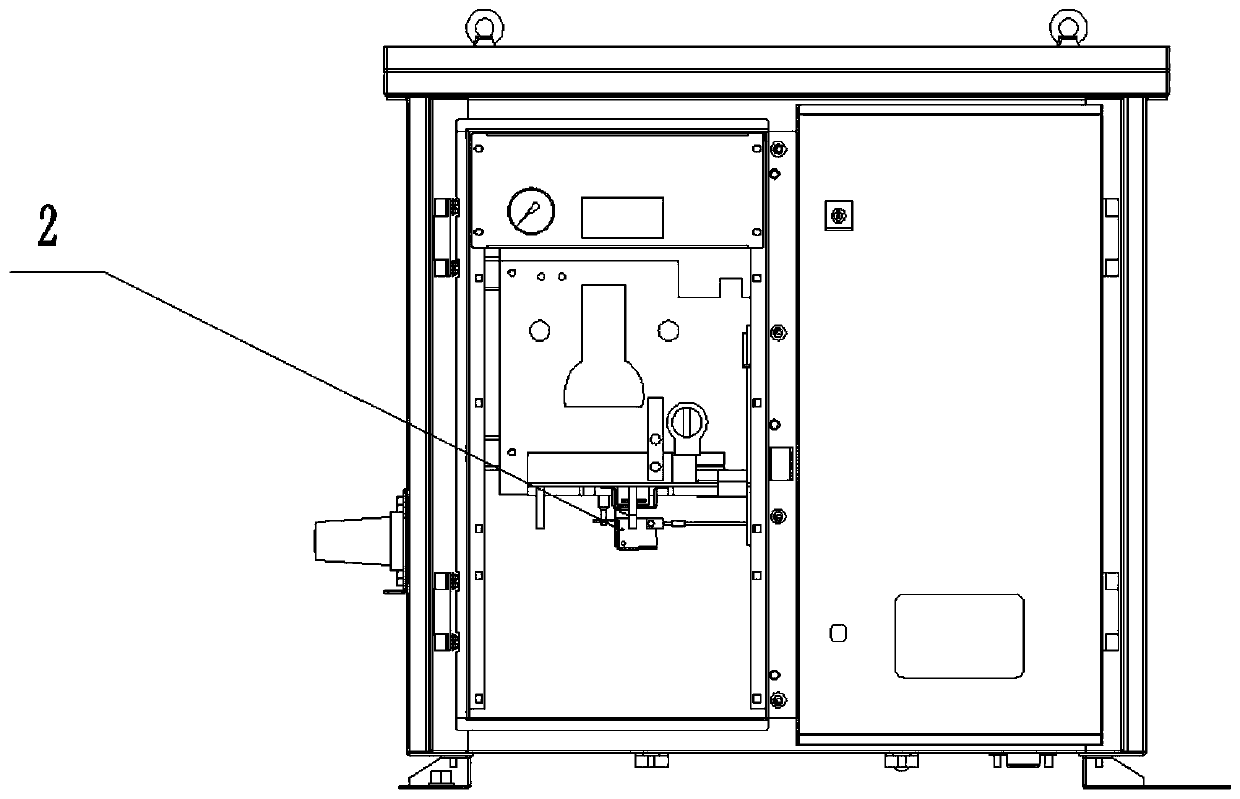

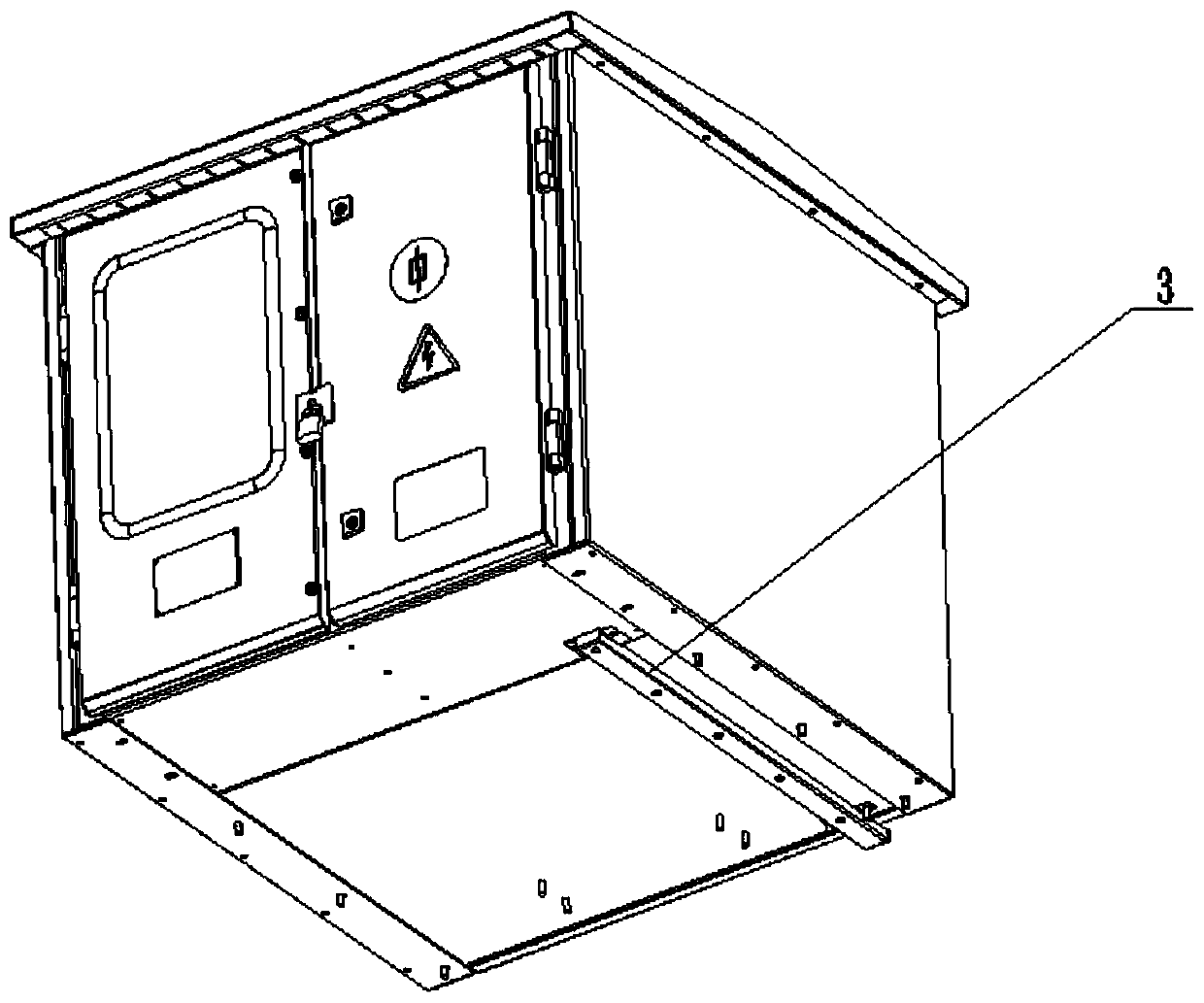

[0057] The integrated intelligent combined box-type substation of the present invention includes a fuse combination cabinet and the fuse combination cabinet is provided with a trip interlock 1 between the mechanism area and the pin-shaped fuse barrel area; the pin-shaped fuse barrel area is provided with a door panel 211 And there is a mechanical interlock 2 between the mechanism area and the door panel 211, and a grounding system 4 is provided for the fuse barrel 412 inside the pin-shaped fuse barrel area; the bottom of the fuse combination cabinet is the bottom of the shell 3 and the bottom of the shell 3 is a double-layer board, the fuse combination cabinet is located inside the outer box 7 of the substation and a transformer 9 is provided under the fuse combination cabinet, and a cable junction box 6 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com