Vibrating diaphragm base material, preparation method thereof, vibrating diaphragm and loudspeaker

A technology of membrane substrate and damping material, applied in the field of loudspeakers, can solve problems such as offset, and achieve the effects of improving stability, suppressing variation, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

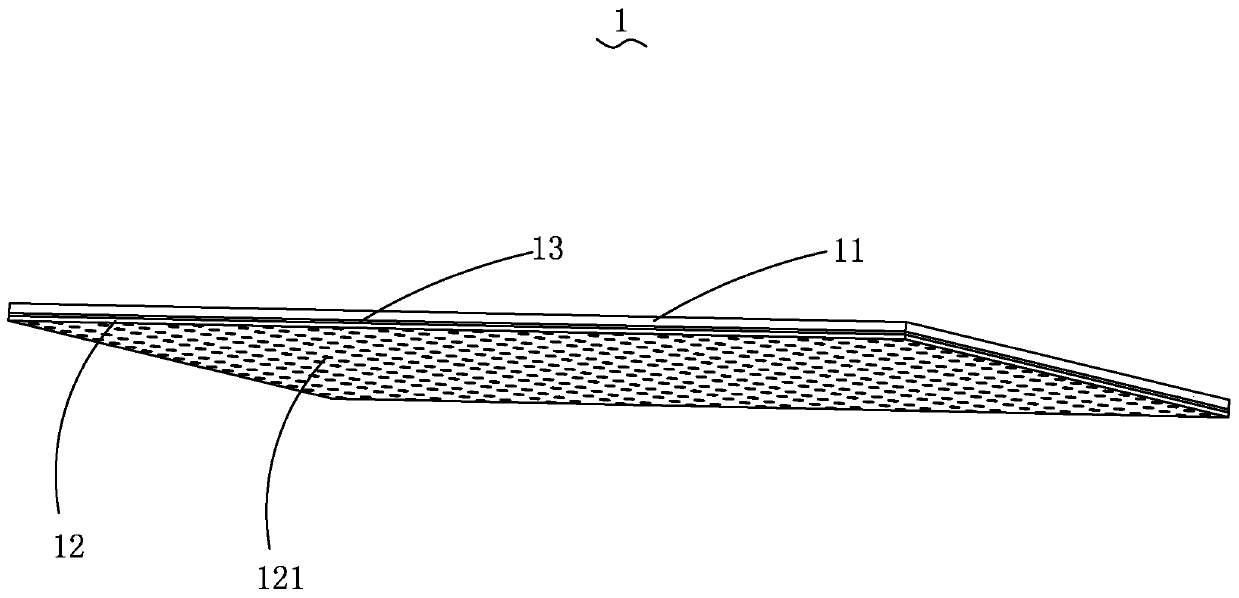

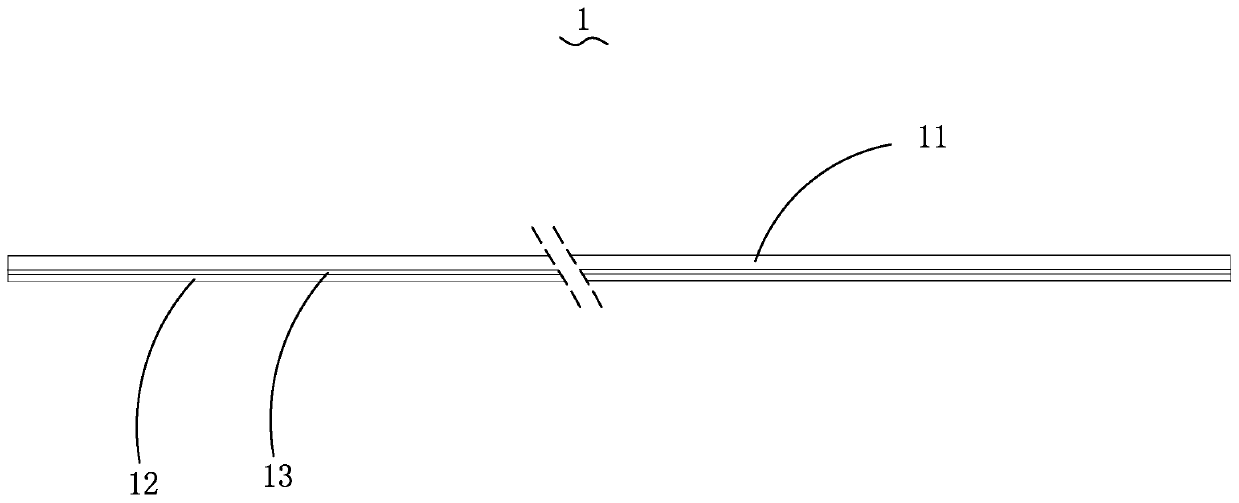

[0035] Such as Figure 2-5 As shown, a diaphragm substrate 1 provided by Embodiment 1 of the present invention includes a polymer material layer 11 made of a polymer material and a porous damping material layer 12 made of a porous damping material. The polymer material layer 11 The stack is fixed on a layer 12 of porous damping material. Because the porous damping material layer 12 is added to the diaphragm base material 1 of this embodiment, the porous damping material has a higher structural strength and can suppress the shrinkage of the polymer material, thus ensuring the use of the diaphragm base material 1 of this embodiment The size of the manufactured product remains consistent, and the diaphragm substrate 1 of this embodiment can suppress and improve the performance variation of polymer materials under high temperature conditions, so the amplitude of products such as speakers using the diaphragm substrate 1 of this embodiment increases with temperature. The high offse...

Embodiment 2

[0048] Such as Figure 8 As shown, the difference between the present embodiment and the first embodiment is that, in the first embodiment, the polymer material layer 11 and the porous damping material layer 12 are fixed together by bonding; while in the present embodiment, the polymer material layer 11 The polymer material layer 11 is fixed together with the porous damping material layer 12 by high temperature molding, and the polymer material made of the polymer material layer 11 is embedded in the through hole 121 in the porous damping material layer 12 .

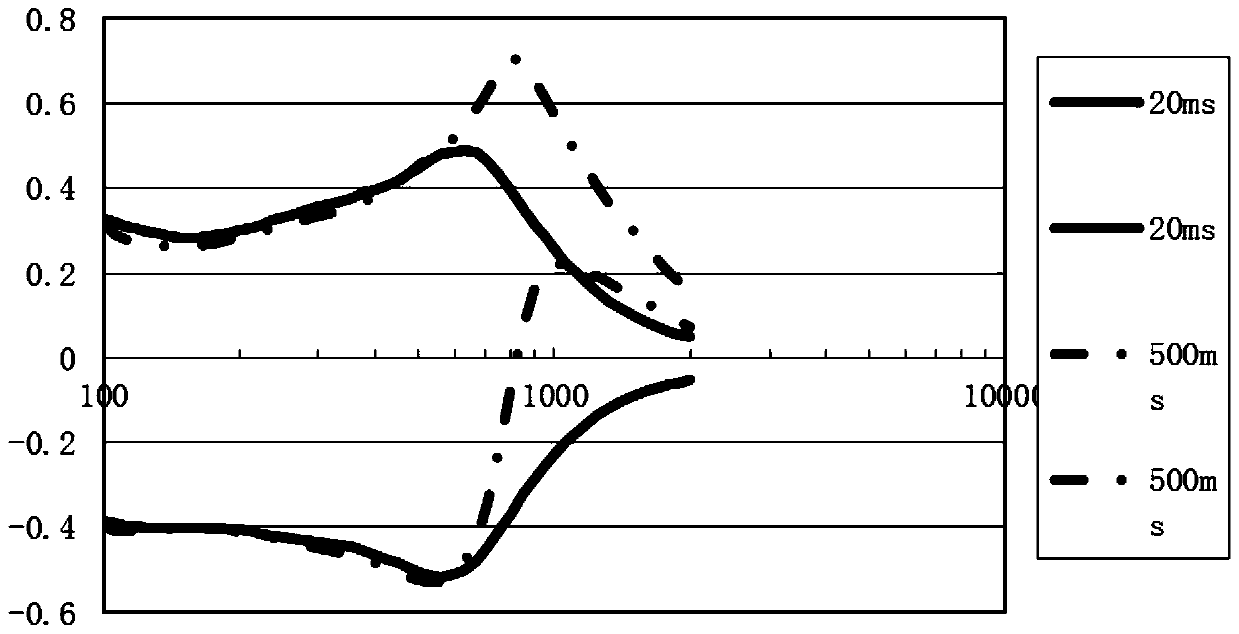

[0049] Such as Figure 9 As shown, it is the vibration amplitude change diagram of the vibrating film base material 1 of this embodiment at different temperatures for 20 ms and 500 ms respectively. time. From the figure, we can see that the amplitude deviation of the same point on the product is small under the test conditions of 20 ms and 50 ms for the diaphragm substrate 1 of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com