Electronic component mounting device and electronic component mounting method

An electronic component installation and component technology, applied in electrical components, electrical components, circuits, etc., can solve the problems of stop position error, long moving time, difficult to obtain position accuracy, etc., and achieve short cycle time and high-precision position alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

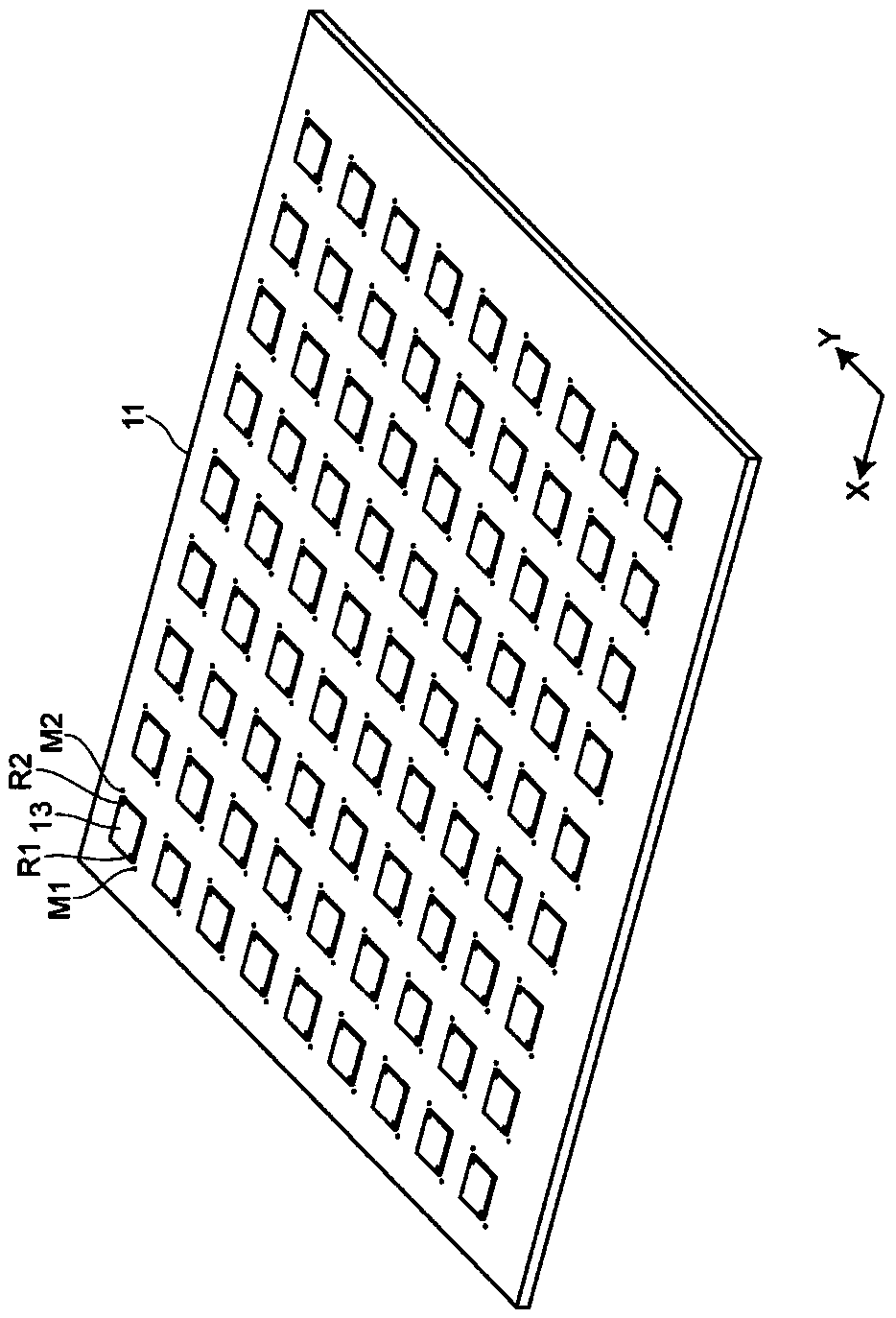

[0033] Hereinafter, for the electronic component mounting apparatus 1 and the electronic component mounting method in the embodiment of the present invention, reference will be made to Figure 1-Figure 5 Be explained.

[0034] [Structure of Electronic Component Mounting Device 1 ]

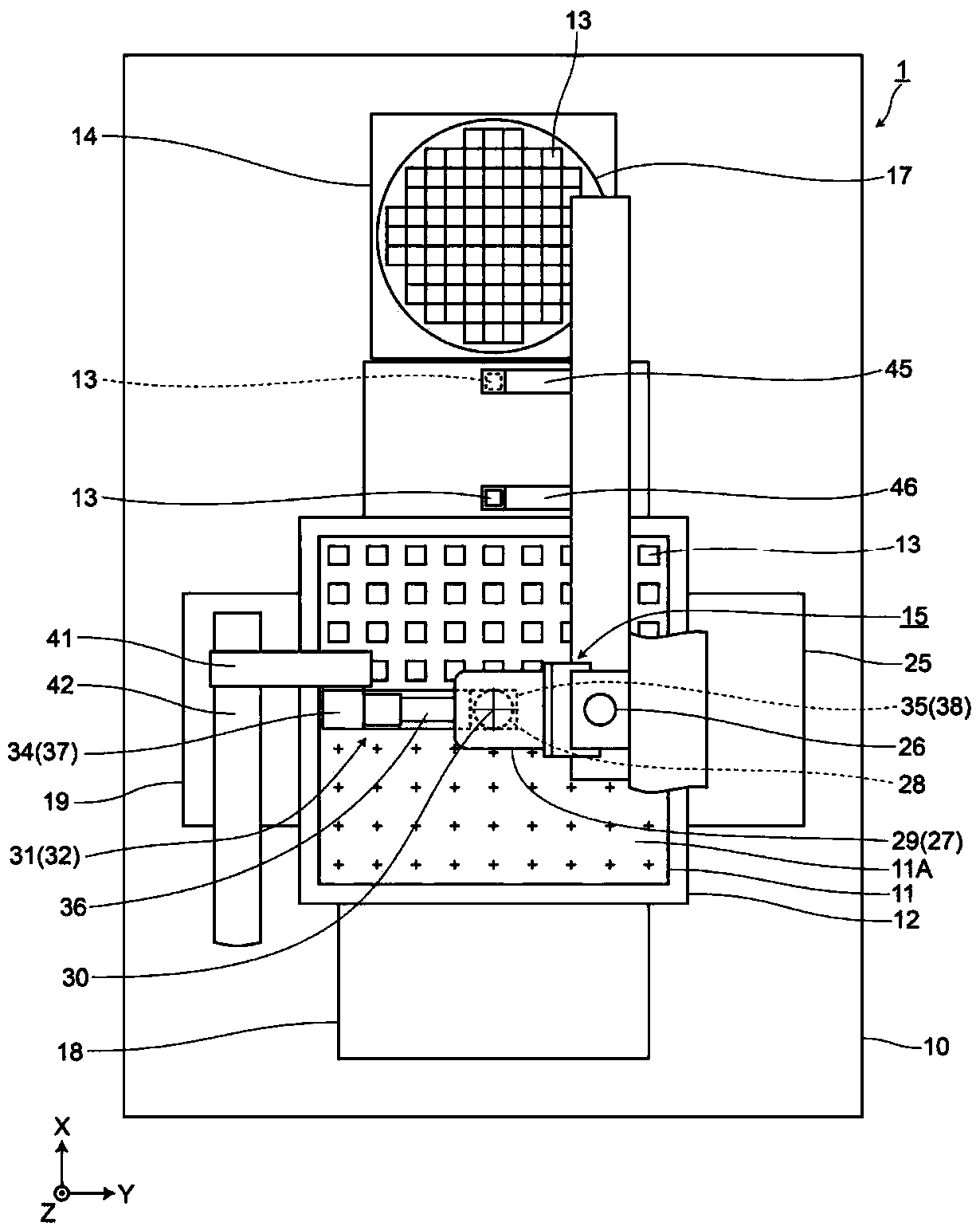

[0035] figure 1 It is a plan view showing a rough structure of the electronic component mounting apparatus 1 in the embodiment,

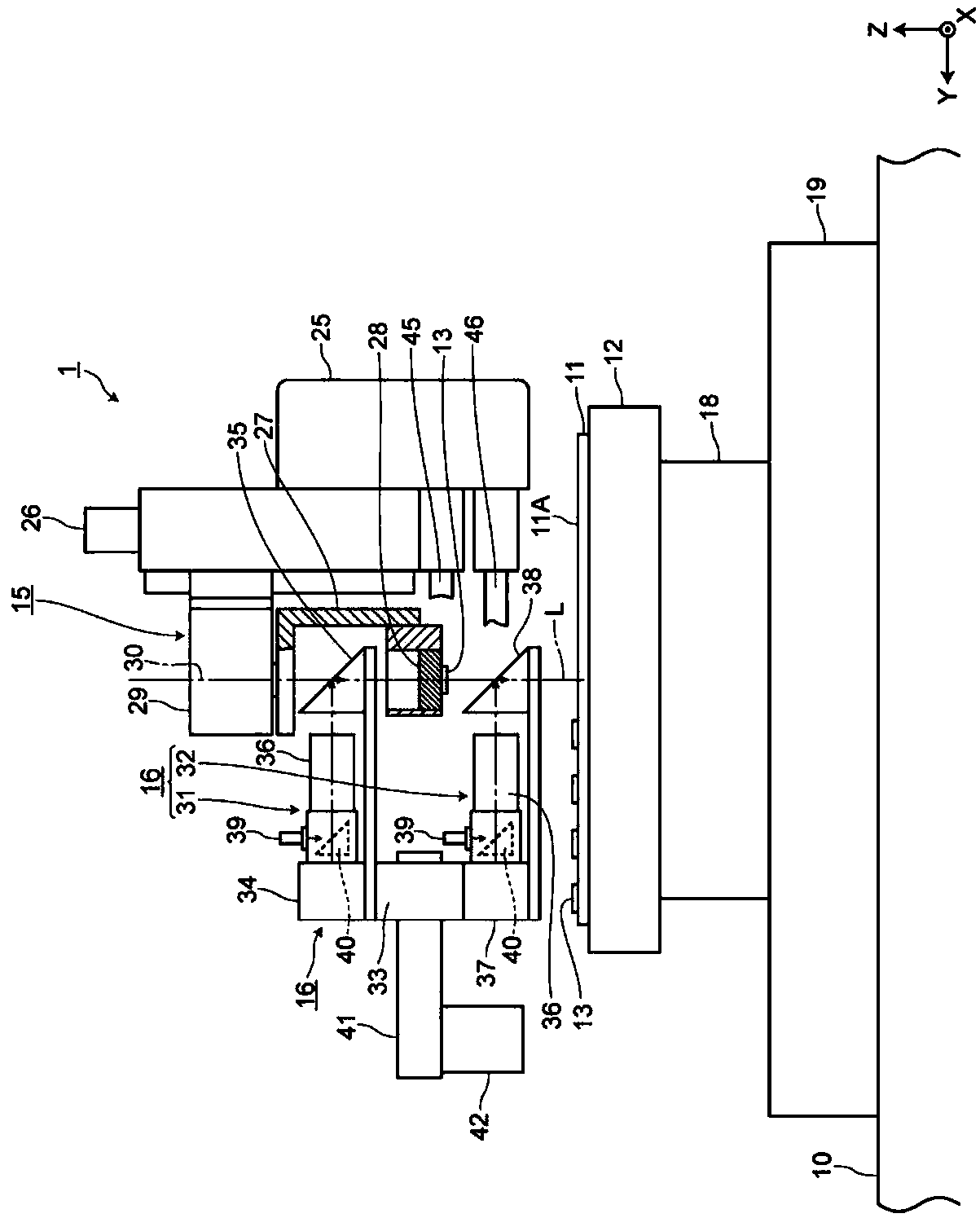

[0036] figure 2 is displayed from figure 1 A front view of the electronic component mounting apparatus 1 seen from the lower side of the figure. The figure described below, will figure 1 The left-right direction in the diagram is referred to as the Y direction or the Y axis, and the up-down direction in the diagram is referred to as the X direction or the X-axis. Alternatively, the vertical direction with respect to the X-Y plane will be described as the Z direction or the vertical direction.

[0037] refer to figure 1 , figure 2 Next, the structure of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com