Crystal removal device in pipeline

A crystallization device and a technology in the pipeline, applied in the field of cleaning the crystallization device in the pipeline, can solve the problems of affecting the service life of the pipeline, increasing production costs, and injury to the staff, so as to achieve the effect of saving materials, prolonging the service life, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

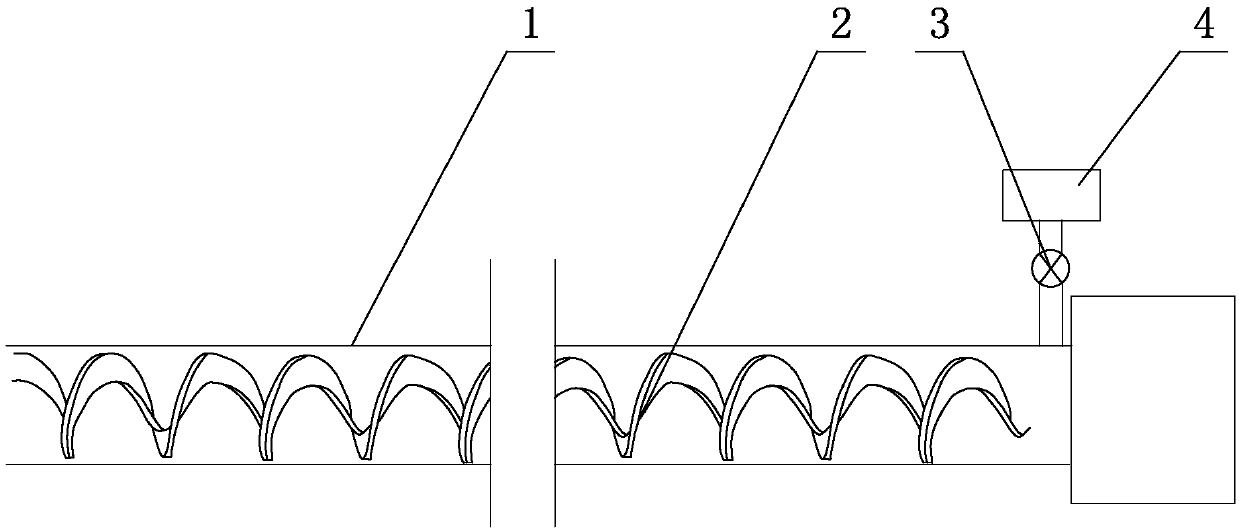

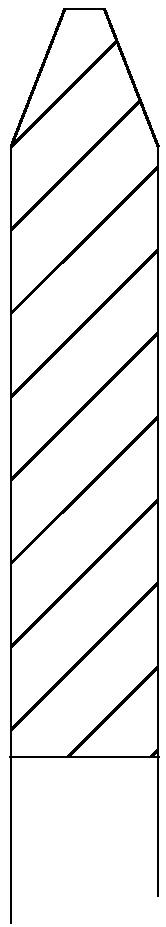

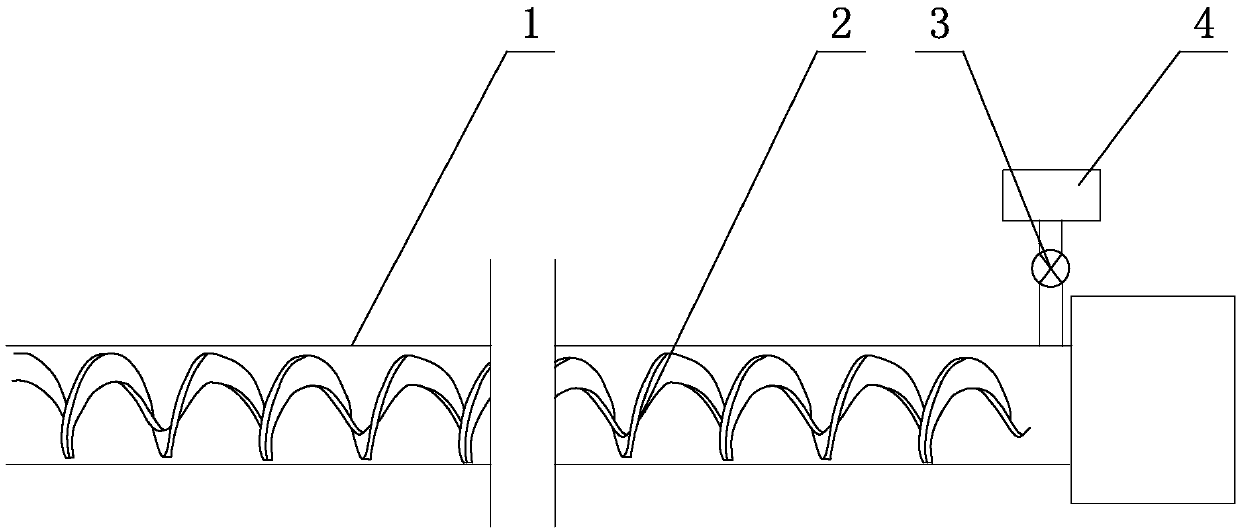

[0016] like figure 1 and figure 2 , the cleaning and crystallization device in the pipeline of the present invention comprises a pipe body 1, a shaftless spiral body 2 is arranged in the pipe body 1, and an air compressor 4 is arranged at the feed port of the pipe body 1, and the air compressor 4 and the pipe body 1 is provided with an air intake valve 3, and the diameter of the shaftless spiral body 2 matches the inner diameter of the pipe body 1.

[0017] In this embodiment: the thickness of the blades of the shaftless helix 2 is 1mm, and both material flow and gas flow can drive the rotation of the shaftless helix 2; the pitch of the shaftless helix 2 is 1 / 2 of the inner diameter of the pipe body 1; the intake valve 3 It is a one-way valve to prevent the backflow of gas, or to prevent the material from flowing into the air compressor 4 when the inlet valve 3 is not cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap