Adjustable trailing gas protection cover for manufacturing electric arc additional material and use method of adjustable trailing gas protection cover

A technology of additive manufacturing and protective cover, applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems affecting the formation of stacked layers, arc and molten pool instability, etc., to improve quality, maintain stability, Avoid oxidative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

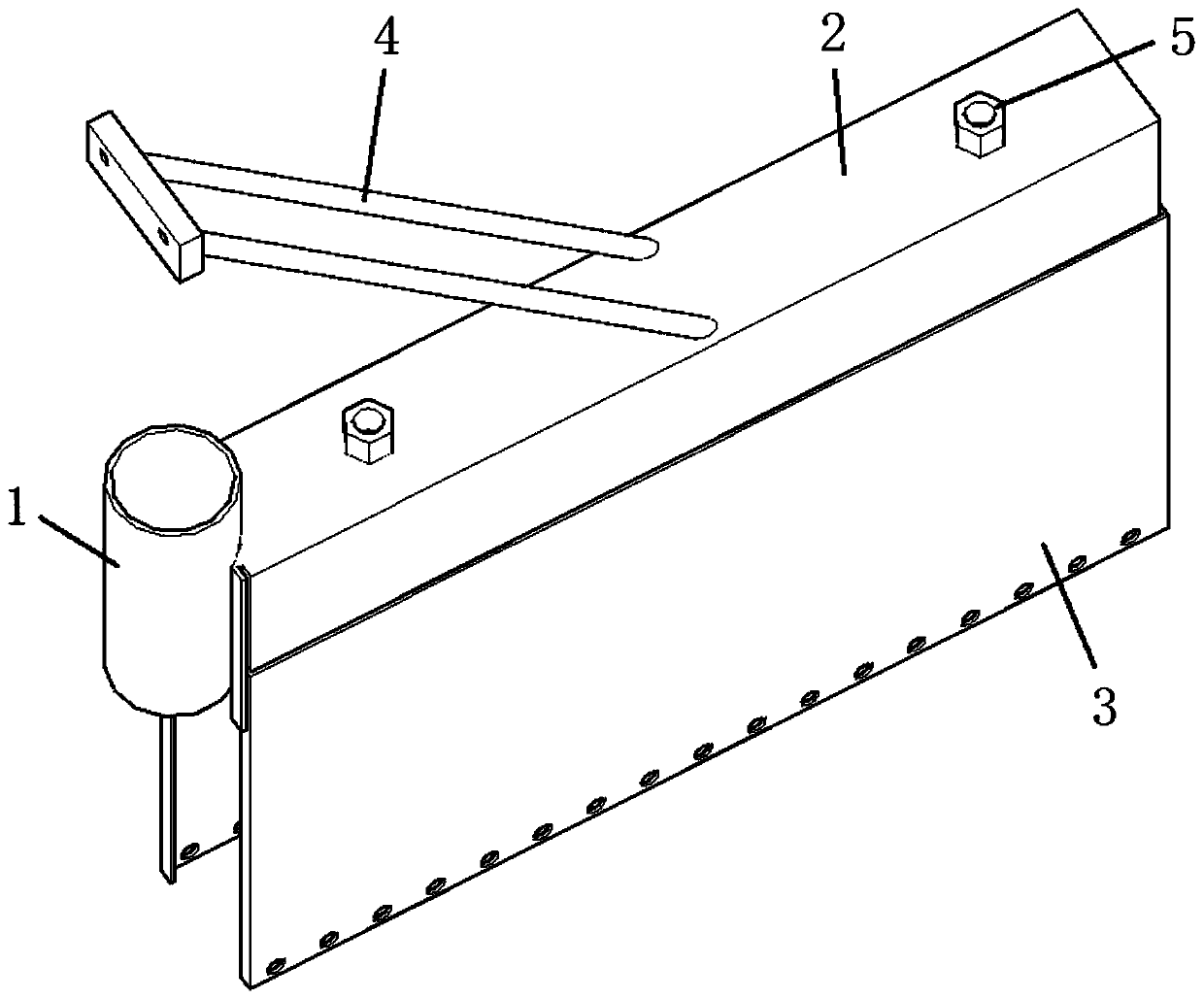

[0029] An adjustable trailing gas shield for arc additive manufacturing, comprising a welding torch sleeve 1, an inner shield 2 and an outer shield 3;

[0030] The inner protective cover includes a front panel, a rear panel, an upper panel and end panels on both sides, and the five panels form a cuboid structure with an open bottom, and a welding torch sleeve is arranged on one end panel of the inner protective cover. The welding torch sleeve is a cylindrical structure with both upper and lower openings; the end panel on the side where the inner protective cover is connected to the welding torch sleeve is arc-shaped to fit the cylindrical outer wall of the welding torch sleeve.

[0031] The inner protective cover is provided with a fixing device 4 for connecting with the welding torch, and the upper panel of the inner protective cover is provided with two intake nuts for connecting with the shielding gas intake pipe; one is close to the welding torch, and the other is far away ...

Embodiment 2

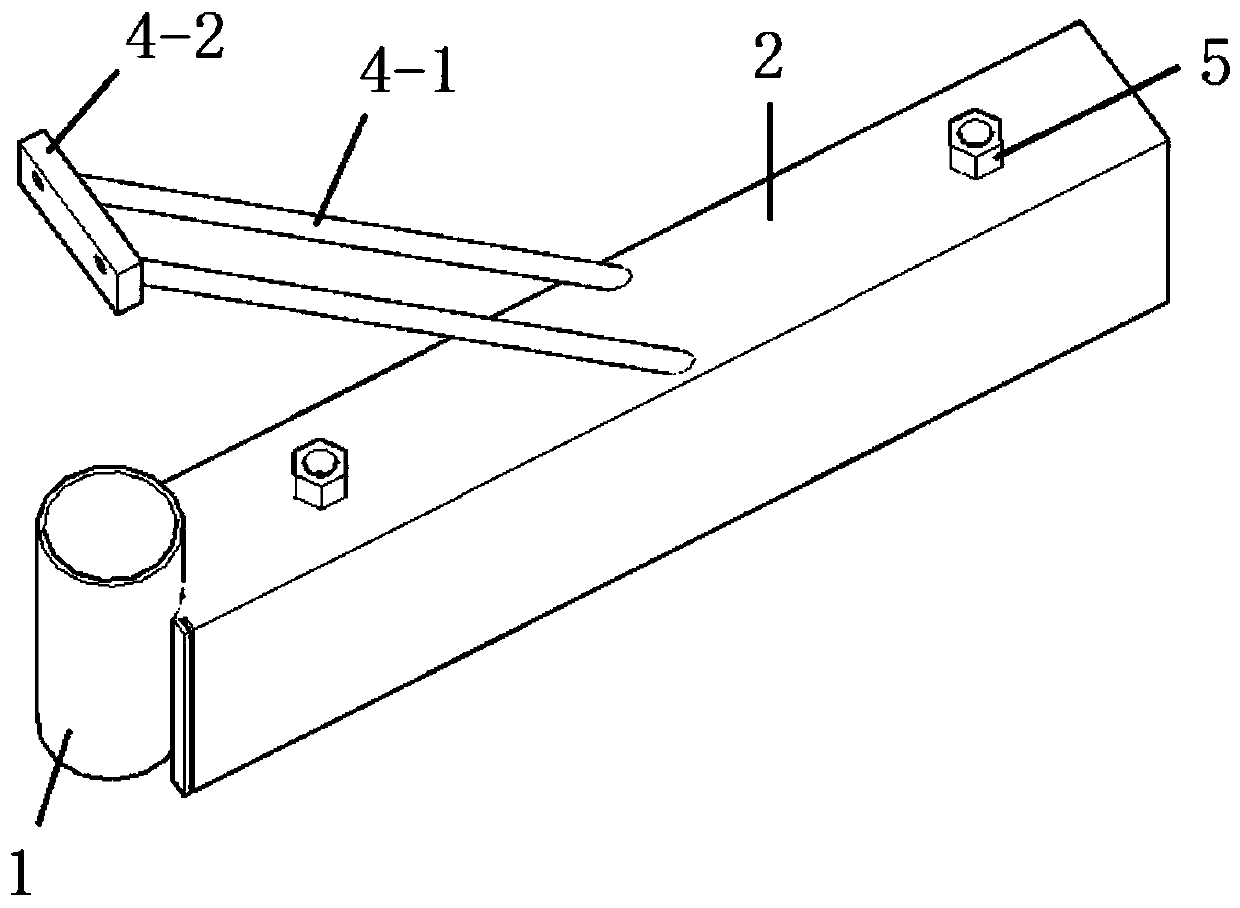

[0036] On the basis of Embodiment 1, the fixing device is composed of connecting rods and connecting pieces (such as figure 2 shown), the connecting piece is fixedly connected to the welding torch or the mechanical arm holding the welding torch, and the connecting rod is arranged between the connecting piece and the upper panel of the inner protective cover. Before arc addition, the connecting piece of the fixing device is connected and fixed with the welding torch or the mechanical arm holding the welding torch, so that the inner protective cover can move horizontally or vertically with the welding torch.

Embodiment 3

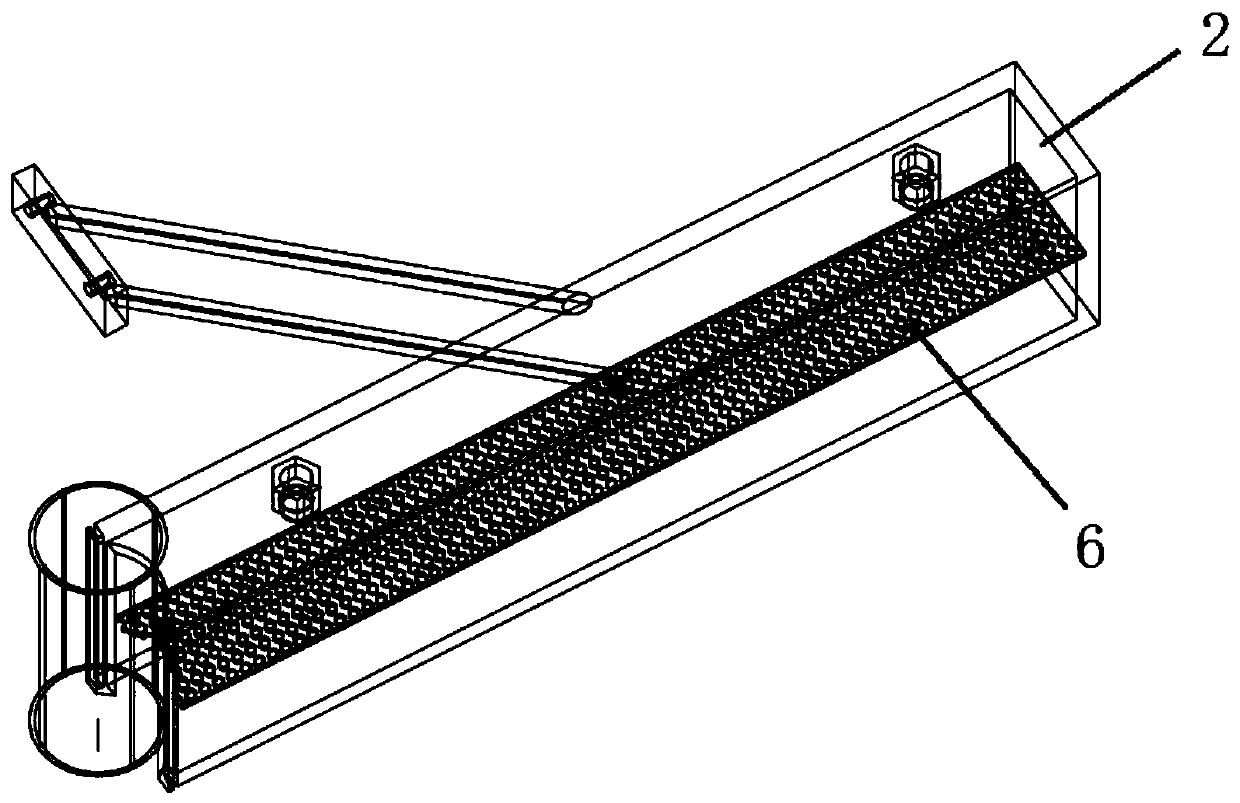

[0038] On the basis of the above-mentioned embodiment 1, the inside of the inner protective cover is provided with a metal screen along the horizontal direction (such as image 3 shown) to distribute the shielding gas evenly. The metal screen is a pure copper screen with a mesh diameter of 0.1 mm and a hole pitch of 0.2 mm; when the arc is added, the shielding gas passes through the air inlet in turn, and the metal screen reaches the substrate. The metal screen plays the role of buffering and dispersing the gas, so as to prevent the excessive gas flow from disturbing the arc and the molten pool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap