Efficient horizontal type machining central machine tool with double main shafts and double work tables

A dual-table and machining center technology, applied in the field of CNC machine tools, can solve problems such as the inability to meet high-efficiency machining of cutting workpieces, and achieve the effects of improving overall stability, convenient maintenance and replacement, and improving dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

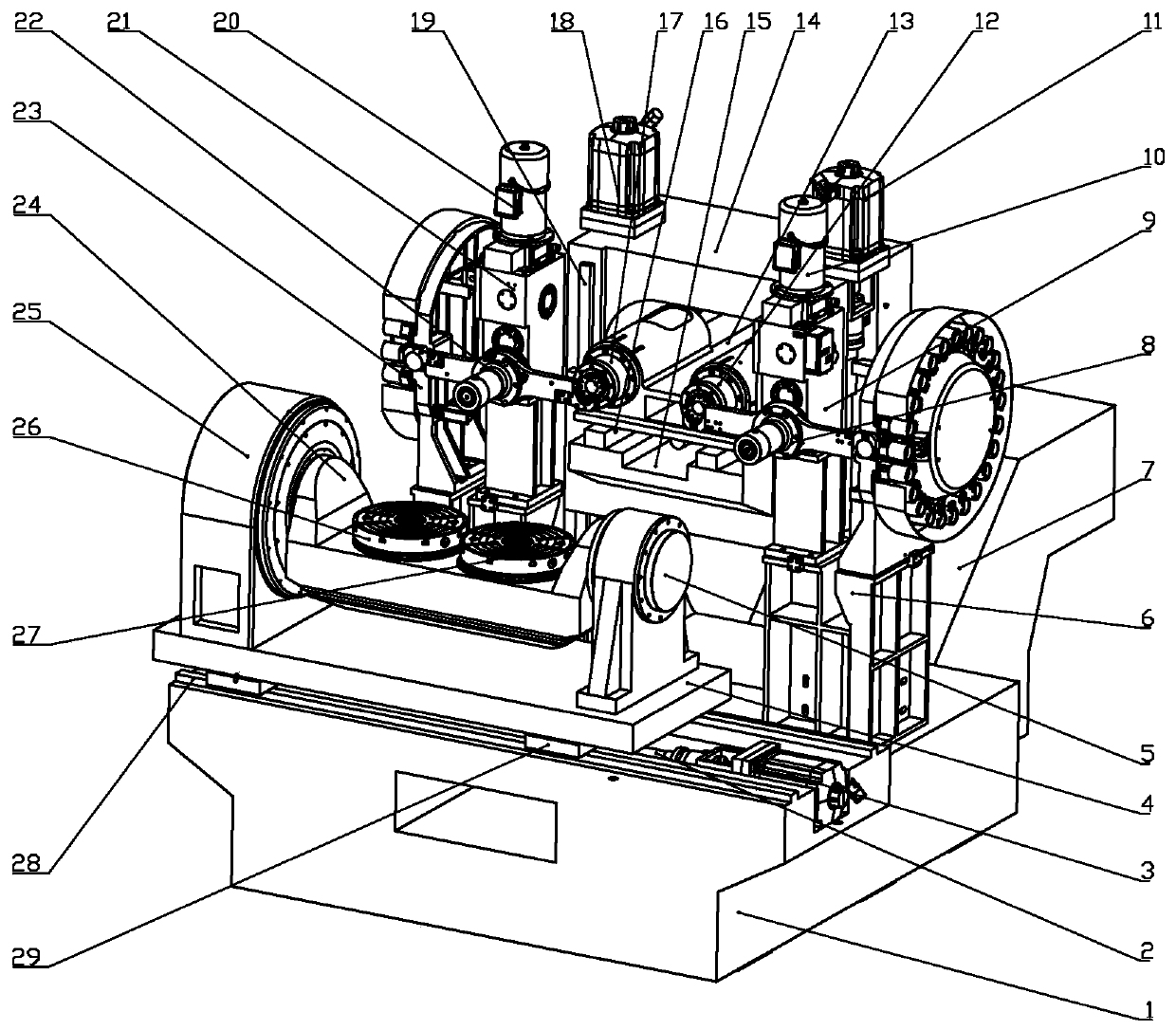

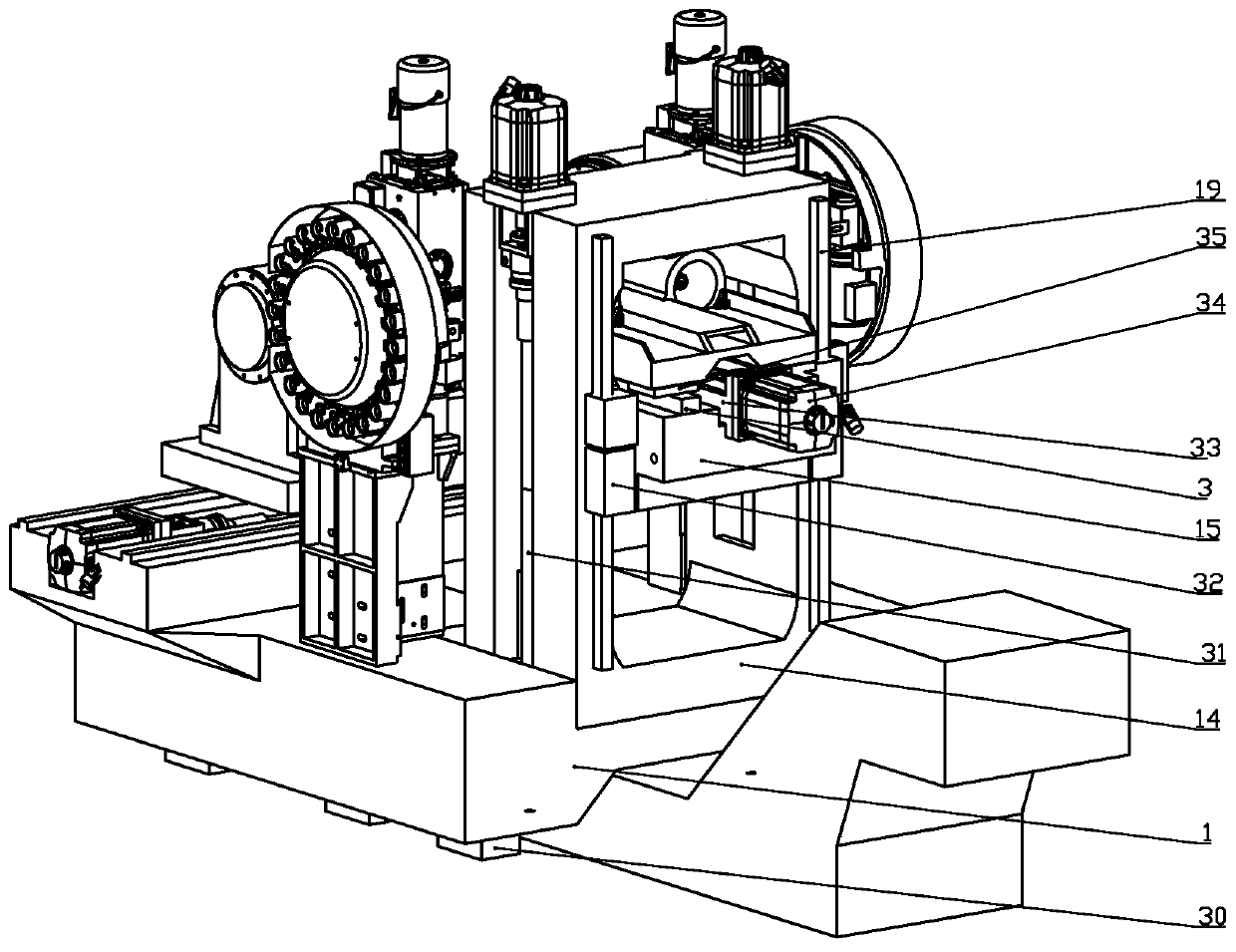

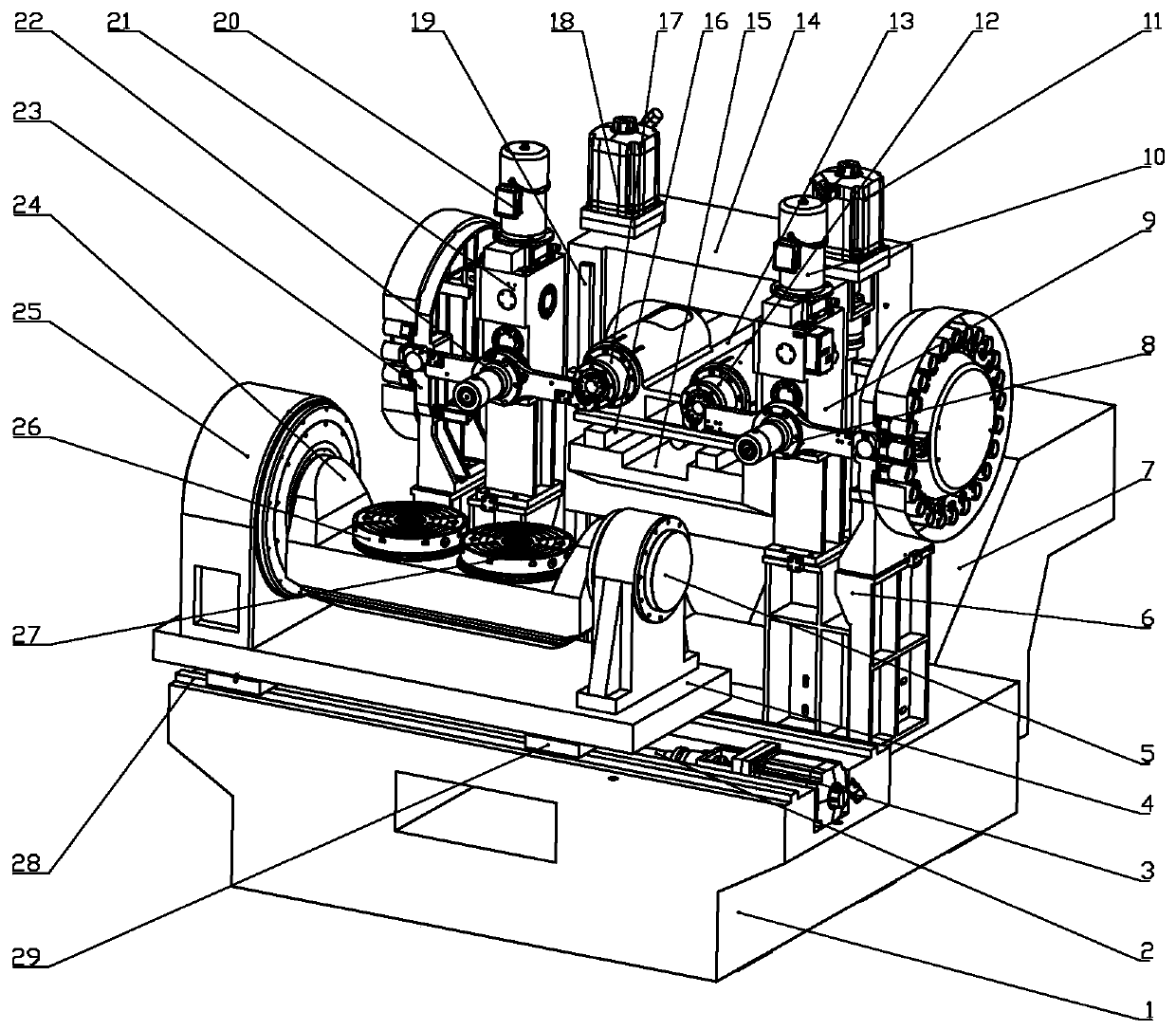

[0016] Such as figure 1 and figure 2 Shown is a high-efficiency horizontal machining center machine tool with double spindles and double worktables disclosed in the present invention, which includes a bed 1 fixed on the ground by feet 30, and an X guide rail 28 provided at the front end of the bed 1 , X-direction driving screw 2 and X-direction drive motor 3; Described X guide rail 28 is provided with X-direction slide block 29, and described X-direction slide block 29 is fixed with cradle connecting plate 4, and described cradle connecting plate 4 The upper, left, and right ends are respectively provided with a cradle left end support shaft unit 5 and a cradle right end support shaft unit 25, and a rocker arm 24 is arranged between the cradle right end support shaft unit 25 and the cradle left end support shaft unit 5, and on the rocker arm 24 A first rotary table 26 and a second rotary table 27 are arranged in sequence along the X direction. The X-direction drive motor 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com