Loading method and mechanism for high-speed grinding machine for valve rod machining

A valve rod, feeding and conveying mechanism technology, which is applied in the directions of grinding machine parts, metal processing equipment, manufacturing tools, etc., can solve the problem of difficulty in increasing the feeding speed, avoid startup and shutdown, improve processing efficiency, The effect of improving the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

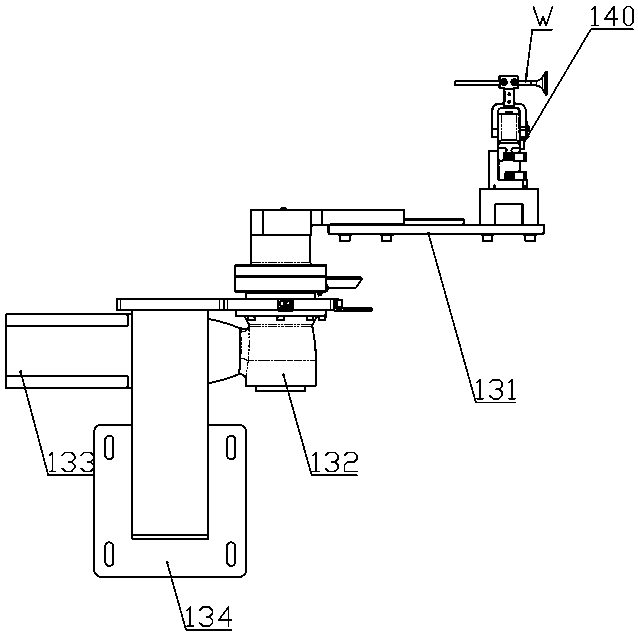

[0021] A feeding method for a high-speed grinding machine used for valve stem processing, comprising the following steps: 1. Clamping the valve stem; Under the shaft rotation state, the valve stem is pushed into the clamp at the front end of the workpiece shaft, and 4, the clamp clamps the valve stem. Among them, in step 3, the material can be quickly ejected at the moment when the mechanical claw releases the support of the valve stem. , the ejector mechanism quickly ejects the valve stem into the fixture.

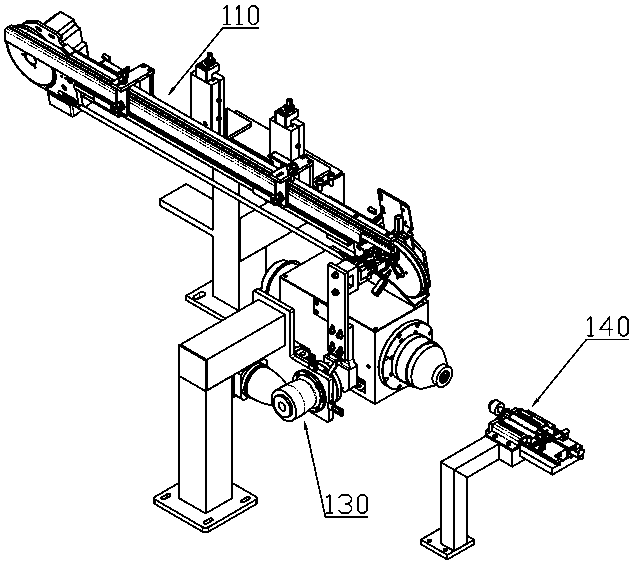

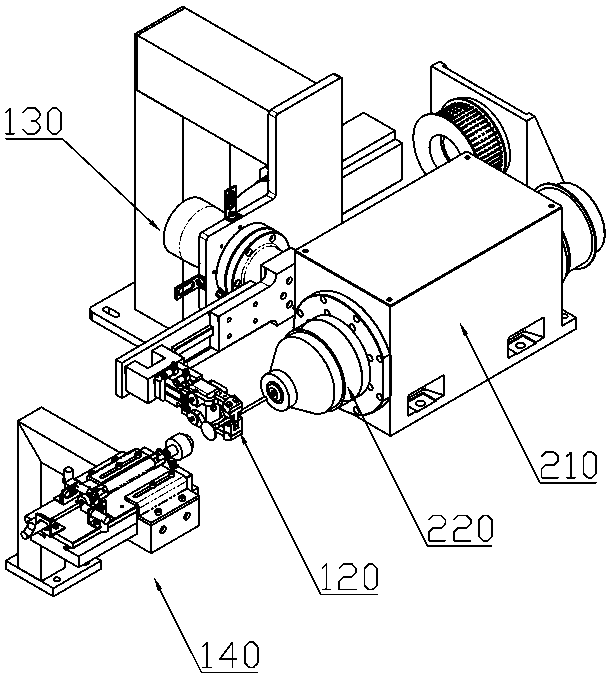

[0022] A feeding mechanism for a high-speed grinding machine used for valve stem processing, such as Figure 1~Figure 6 As shown, it includes a material conveying mechanism 110, a swing arm mechanism 130, a mechanical claw 120 and a material ejecting mechanism 140;

[0023] Feed conveying mechanism 110 comprises guide rail 111 and belt transmission mechanism, and belt transmission mechanism comprises belt 112, belt pulley and feeding motor, and the belt 112 of guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com