End path planning algorithm for mortar spraying and plastering construction robot

A construction robot and path planning technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high complexity and unsuitable planning for cement mortar spraying tasks, and achieve high execution accuracy and meet the spraying tasks effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

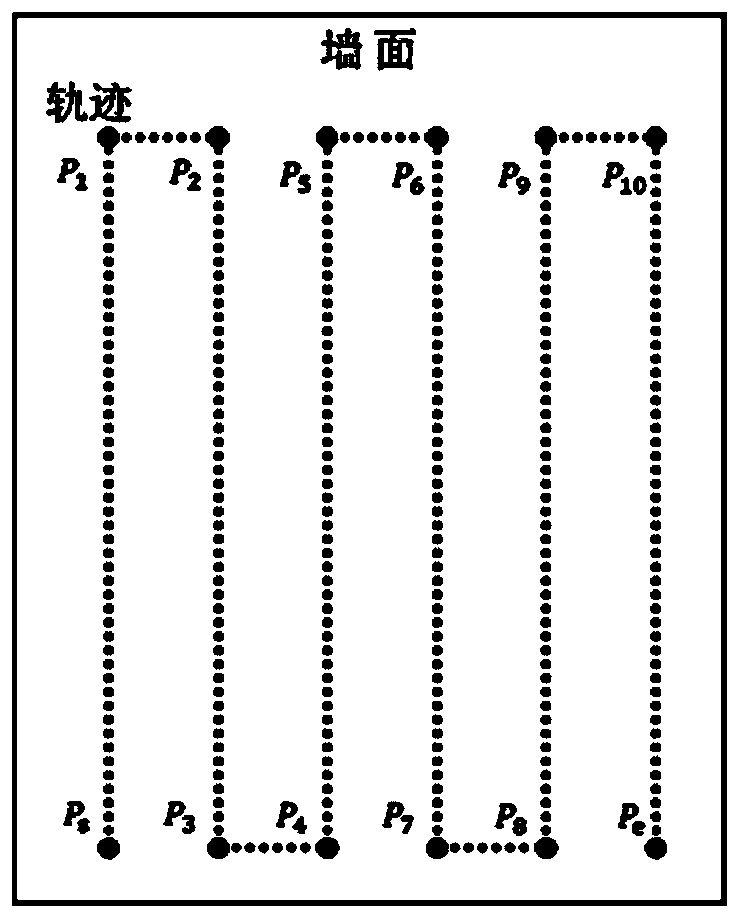

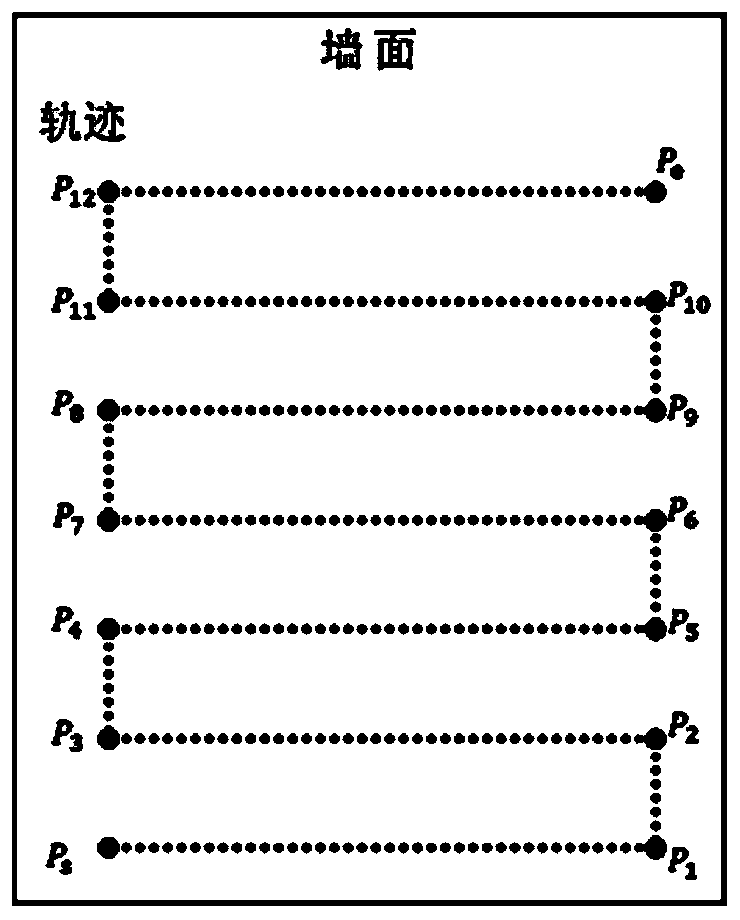

[0031] A terminal path planning algorithm for a mortar spraying construction robot. For different operation walls and task methods, regardless of the current position of the robotic arm, first generate a task execution trajectory that meets the process requirements; then start from the current position of the robotic arm before the work starts Start and complete the free path planning from the current position to the initial position:

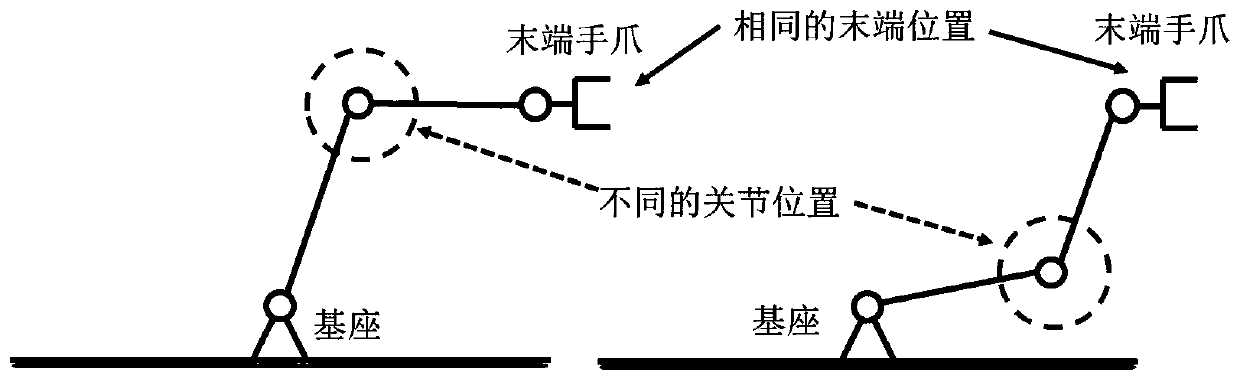

[0032] Task trajectory planning: Determine the task trajectory point where the end of the robot arm moves from the initial position of the task to the end position of the task, calculate the dynamic inverse ungroup for each trajectory point, traverse each inverse solution, and find the path with the highest traversal success rate as the final mission trajectory planning;

[0033] Free trajectory planning: Calculate the joint displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com