Waste tire hole detecting and filling device for waste tire reutilization

A technology for waste tires and holes, which is applied in the field of waste tire hole detection and filling devices, which can solve the problems of laborious manual maintenance, large tire size, and inconvenience, and achieve the effects of ensuring reliability, improving conveying efficiency, and avoiding separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

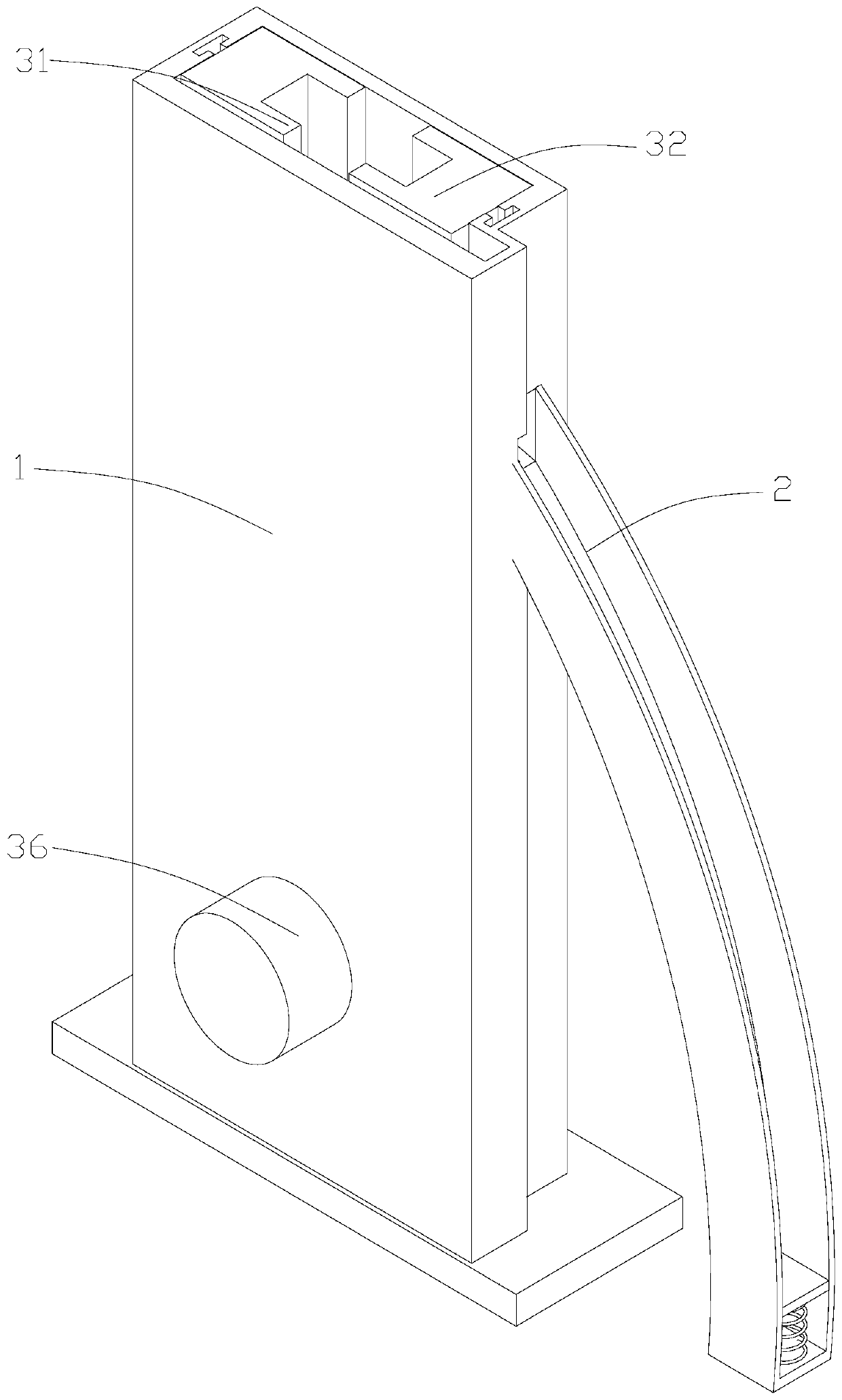

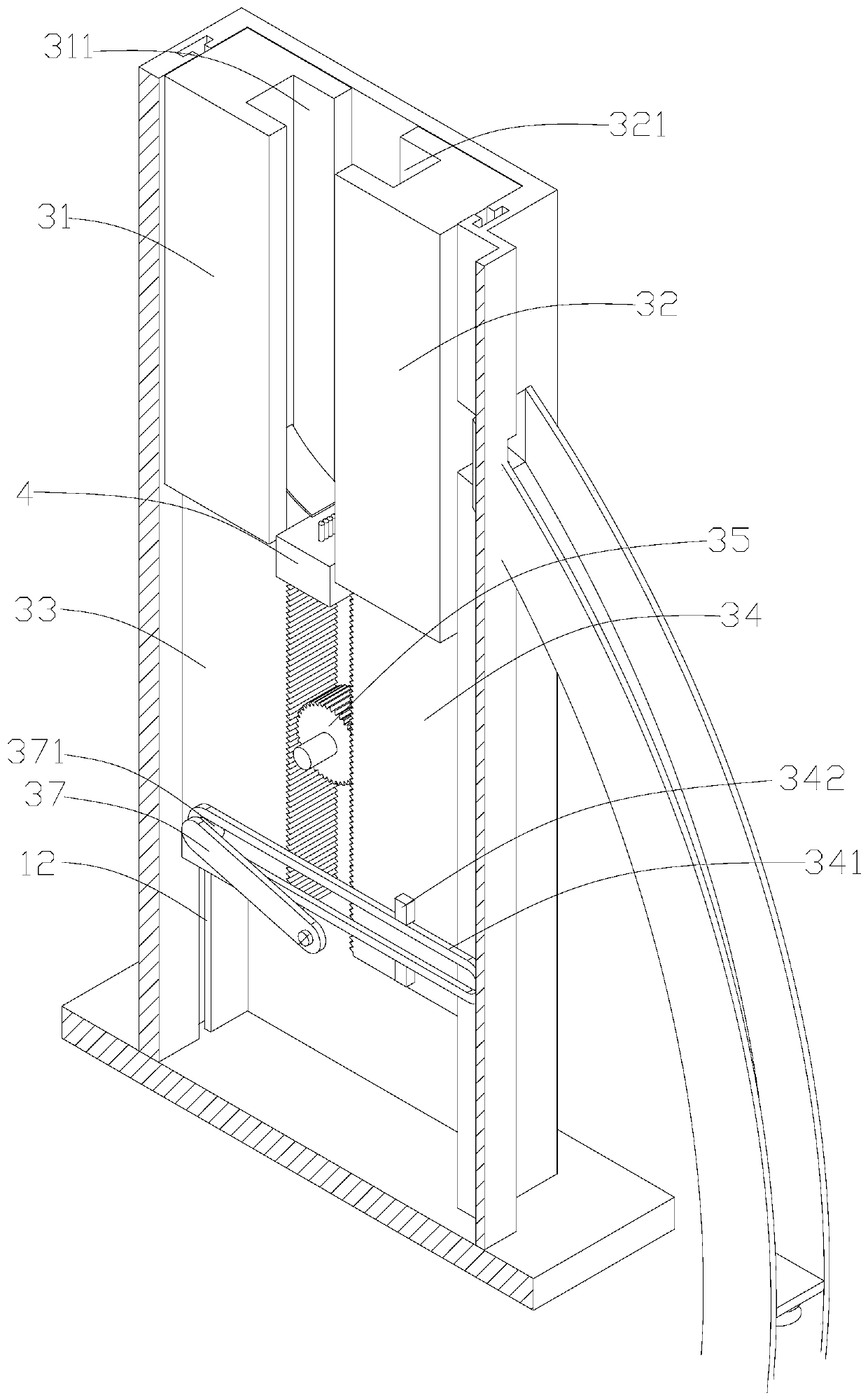

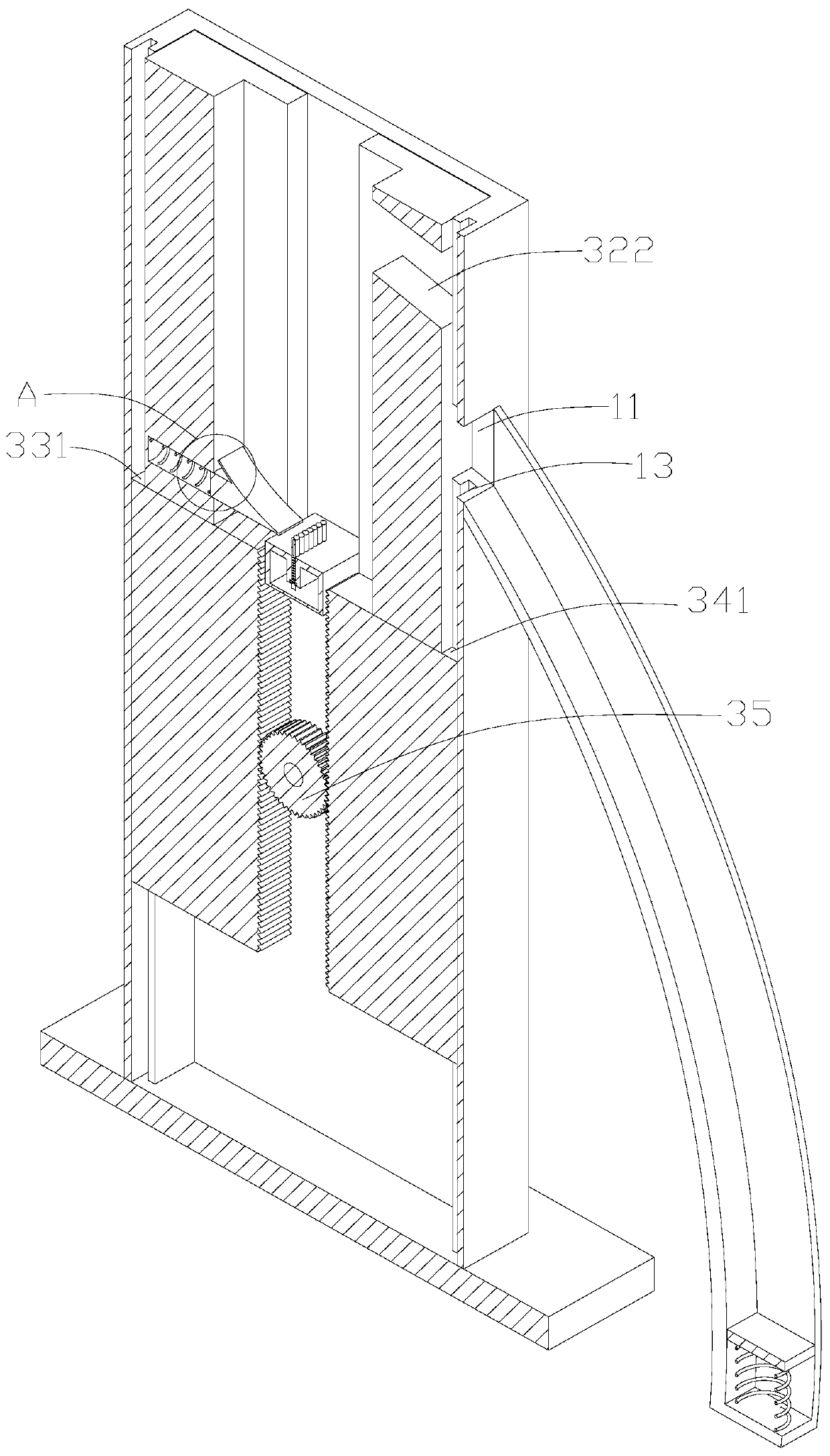

[0025] Such as Figure 1-9 As shown, a waste tire hole detection and filling device for waste tire reuse includes a fixed housing 1 and a feeding channel 2 for transporting the waste tires after the detection and filling. The fixed housing 1 It is provided with a first control block 31 and a second control block 32 for controlling the rotation of the scrap tire after grinding, and a first drive block 33 and a second drive block for driving the first control block 31 and the second control block 32 34 and the tyre-repairing device for detecting and filling the polished waste tires, through the setting of the above structure, the ground waste tires can be clamped by the first control block and the second control block, avoiding waste tires The disengagement ensures the stability of the waste tire during repairing, and the setting of the first driving block and the second driving block enables the waste tire to realize the rotation effect through the first driving block and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com