Forging and pressing device for metallurgical casting

A forging and mounting seat technology, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problems of low work efficiency, achieve effective clamping effect, convenient operation, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

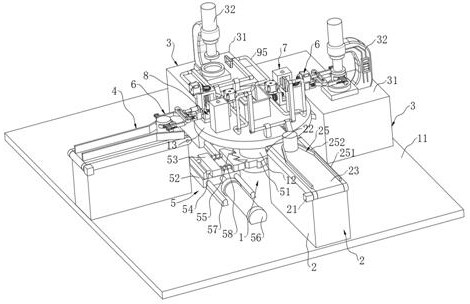

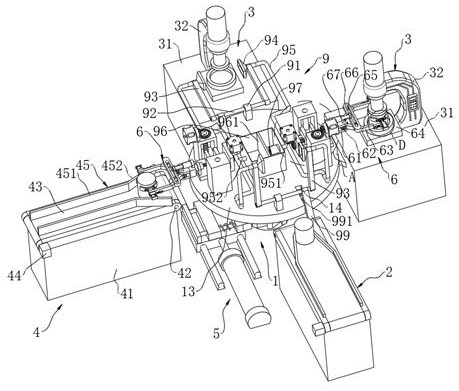

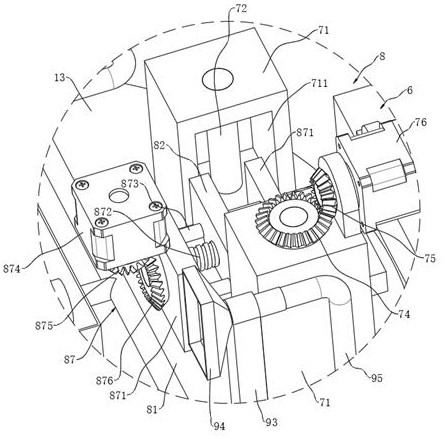

[0027] The disclosure of the embodiment of the present application provides a forging device for metallurgical casting. The clamping mechanism 6 on the transfer table 1 is used to quickly transfer the workpiece, and the driving mechanism 5 drives the pillar 12 to rotate intermittently, so that the clamping mechanism 6 can be effectively Rotating to different stations effectively solves the problem of low work efficiency caused by manual handling of workpieces for forging and pressing in the prior art, realizes automatic handling of workpieces, and improves overall work efficiency.

[0028] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0029] refer to figure 1, a forging device for metallurgical casting, including a transfer table 1, a feed mechanism 2, a forging mechanism 3 and a discharge mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com