Sliding track bracket for fixing deep sea pressure-resistant cabin

A technology of pressure-resistant cabins and slide rails, which is applied to ship components, ships, transportation and packaging, etc. It can solve problems such as difficult installation and maintenance operations, and excessive weight of deep-sea pressure-resistant equipment, so as to reduce operational difficulty and safety risks, reduce The effect of additional weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

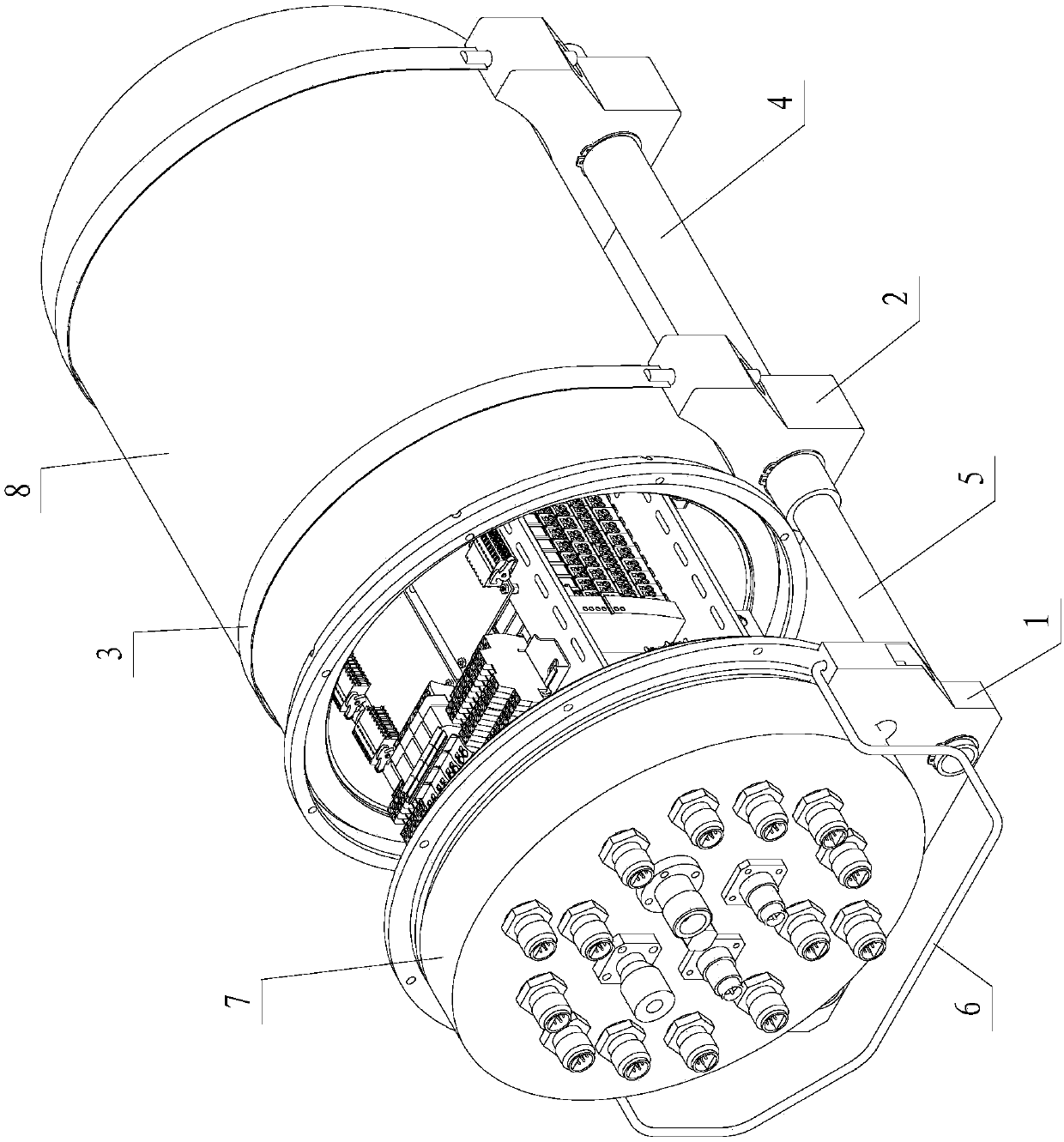

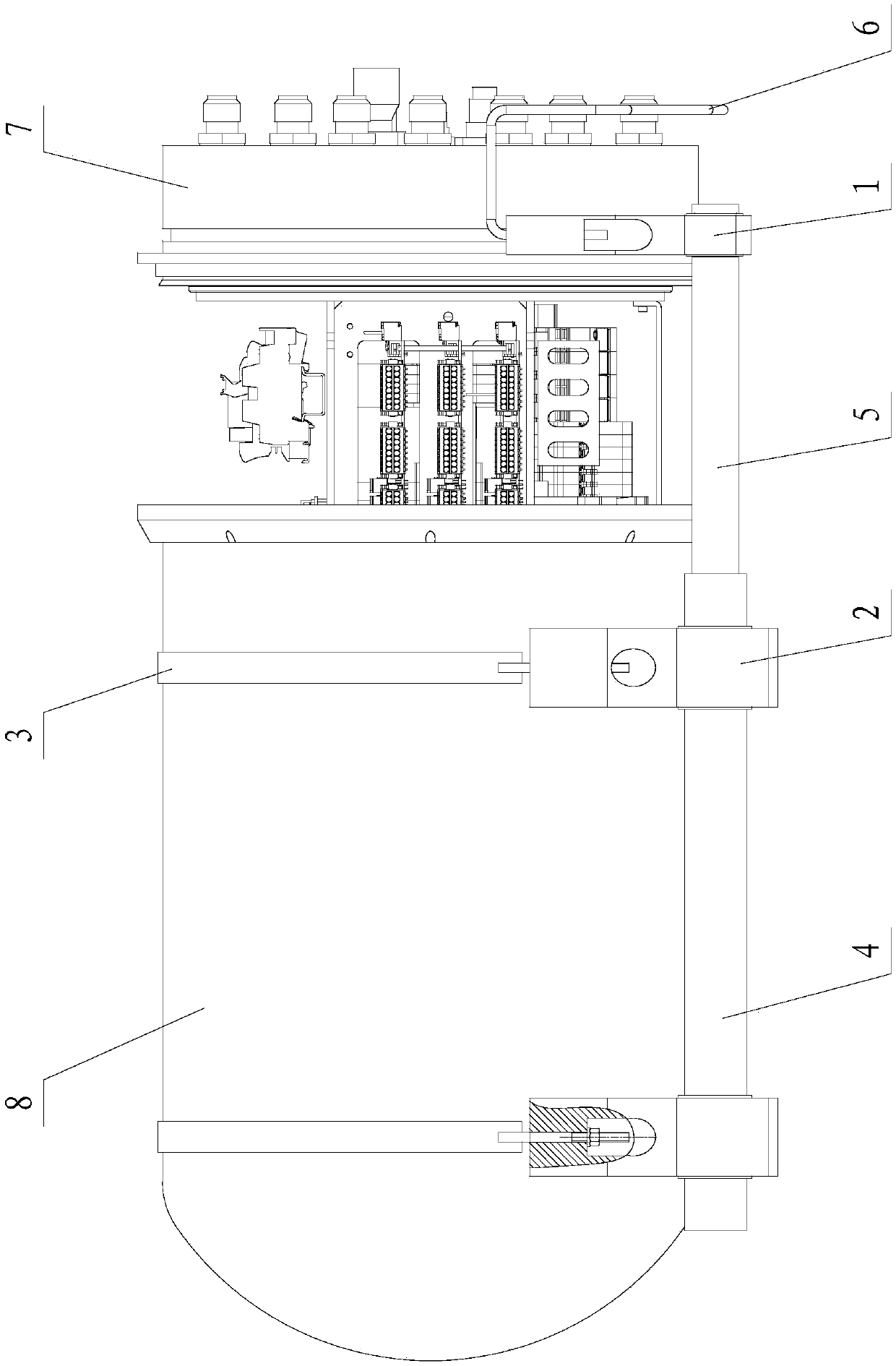

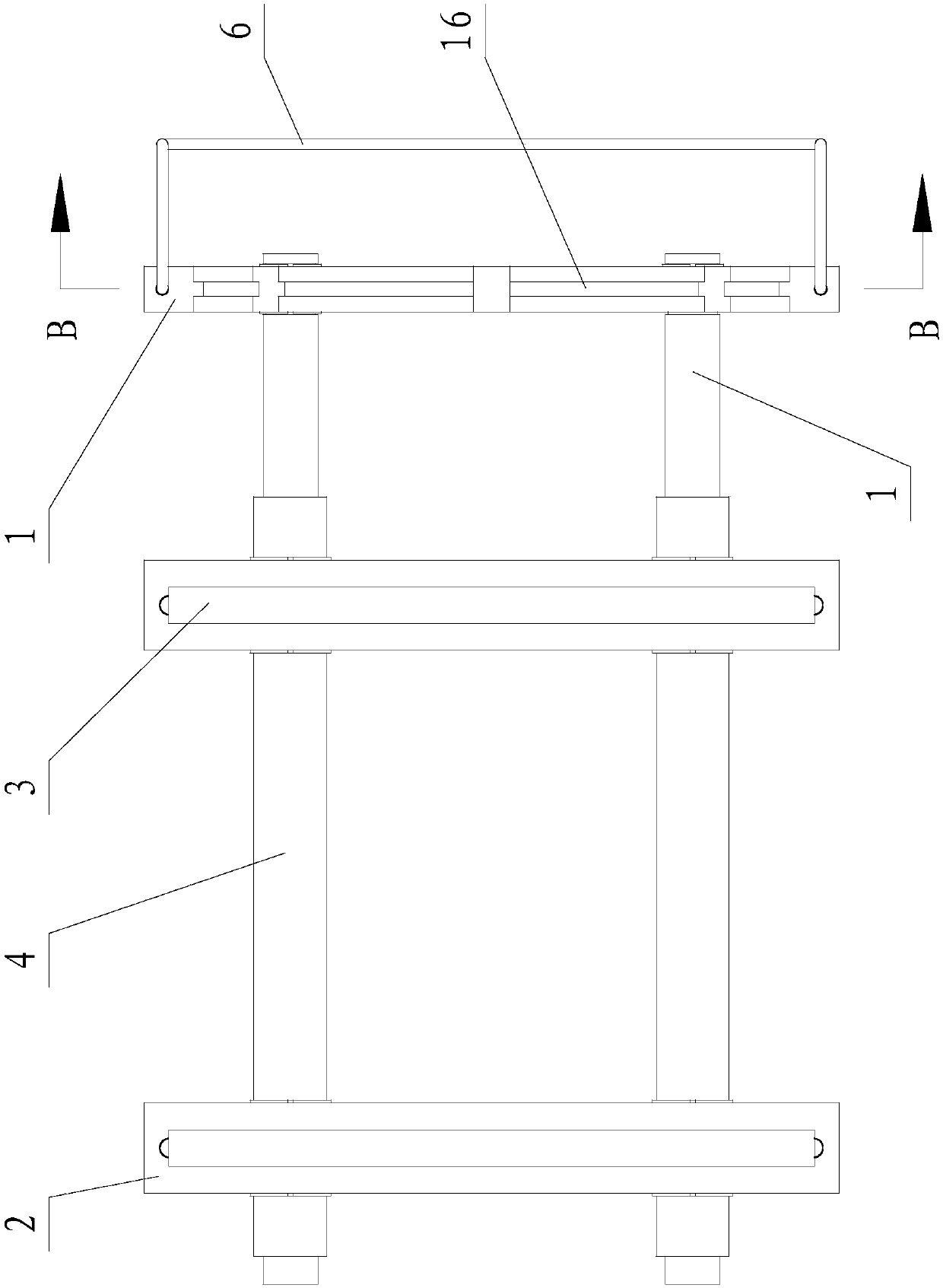

[0026] Such as Figure 1~4 As shown, the present invention includes a hatch cover clamping plate 1, a mounting bracket 2, a cabin body fixing belt 3, a pull rod 6 and a slide rail, wherein the hatch cover clamping plate 1 and the mounting bracket 2 are arranged front and back, and are parallel to each other; in this embodiment There are two mounting brackets 2 and one hatch cover clamping plate 1.

[0027] Each side of the hatch cover clamping plate 1 and the mounting bracket 2 is connected by slide rails, and the two slide rails are parallel to each other. Each slide rail comprises a guide tube 4 and a guide rod 5, the front and rear ends of the guide tube 4 are respectively connected to one side of the two mounting brackets 2, and one end of the guide rod 5 is connected to the hatch cover clamping plate 1 on the same side, The other end penetrates in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com