An Atomized Diffusion Model with Controlled Coarsening Rate

A technology of atomic diffusion and rate, applied in ion implantation plating, design optimization/simulation, vacuum evaporation plating, etc., can solve problems such as low surface roughness and uneven film surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

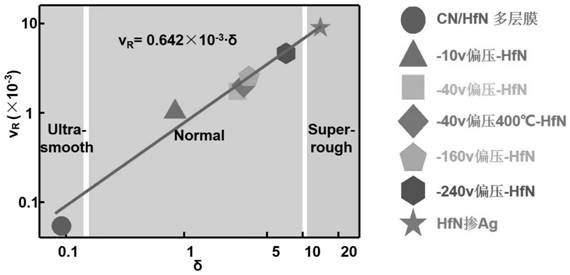

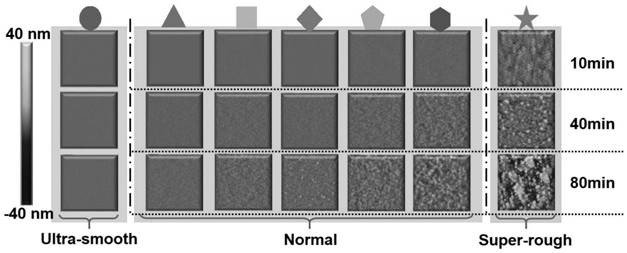

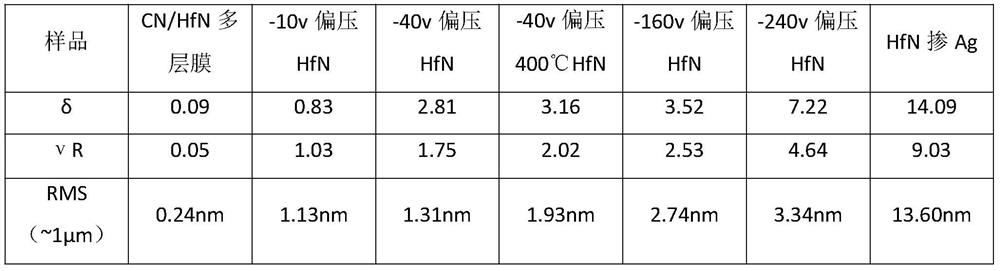

[0021] An atomic diffusion model that regulates the coarsening rate, comprising the following steps:

[0022] (1) The film thickness is measured by a step meter as d, and the root mean square roughness is measured by an atomic force microscope as RMS;

[0023] (2) By calculating the slope of the straight line of RMS-d, the slope is the coarsening rate νR;

[0024] (3) RMS and d in the step (1) are imported into the Gwyddion software, and the surface morphology is simulated by the Gwyddion software;

[0025] (4) Through Gwyddion software simulation, it can be known that the protrusion size data h and s on the surface of the film, h is the size of the protrusion in the vertical direction, and s is the size of the protrusion in the horizontal direction;

[0026] (5) Select a thin film for deposition. With the continuous deposition of atoms, when the thickness of the film increases to d0+Δd, the size of the protrusion in the vertical direction is h0+Δh, and the size in the horizo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com