Cladding power stripping device and laser device

A power and cladding technology, which is applied in the direction of lasers, laser components, laser components, etc., can solve the problem that the power stripping of the cladding cannot meet the demand, and achieve the effect of reliable stripping and preventing the overheating of the optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

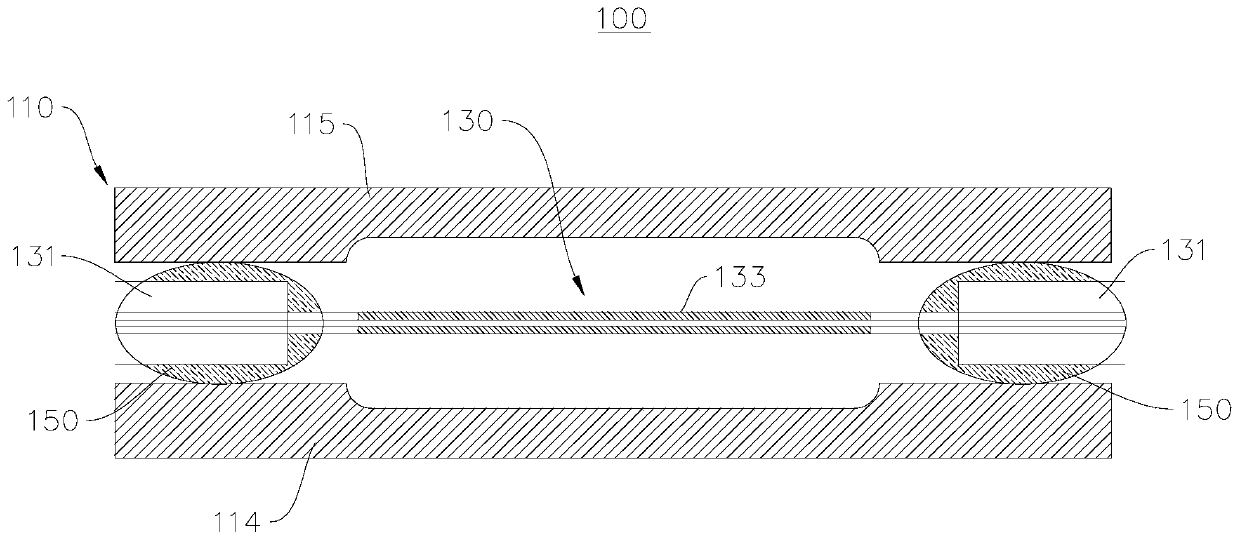

[0033] see figure 1 , this embodiment provides a cladding power stripping device 100 , and the cladding power stripping device 100 includes a cooling shell 110 , an optical fiber 130 and a glue layer 150 . The optical fiber 130 is disposed in the cooling housing 110 , and the optical fiber 130 is fixedly connected to the cooling housing 110 through the adhesive layer 150 .

[0034] The optical fiber 130 includes a bare fiber section 133 for cladding power stripping, and also includes a coating section 131 including a coating layer, and the coating section 131 is located on both sides of the bare fiber section 133 .

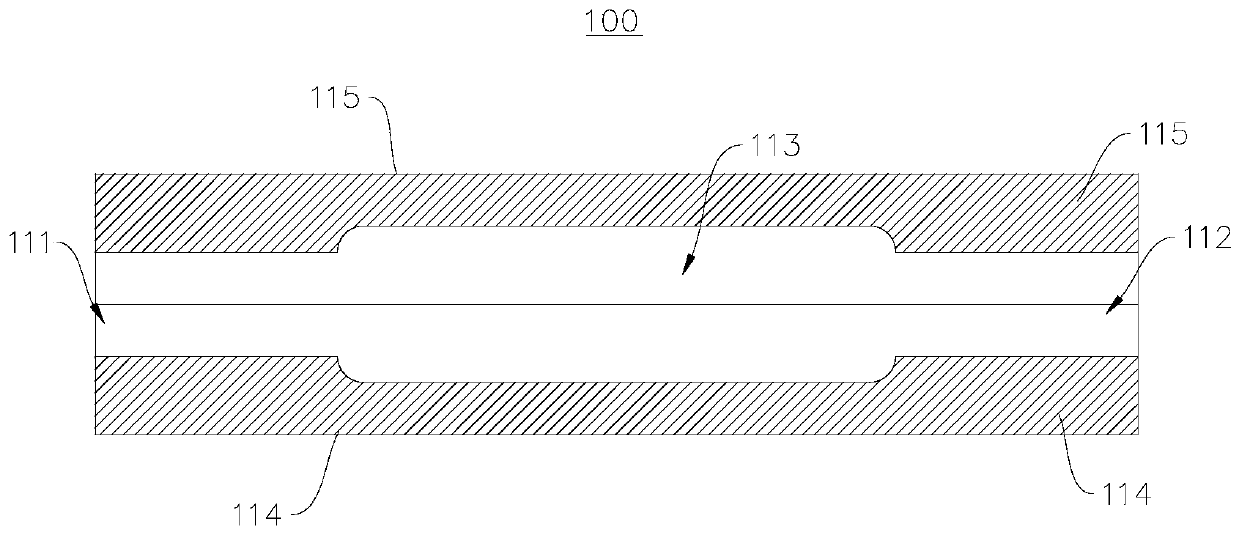

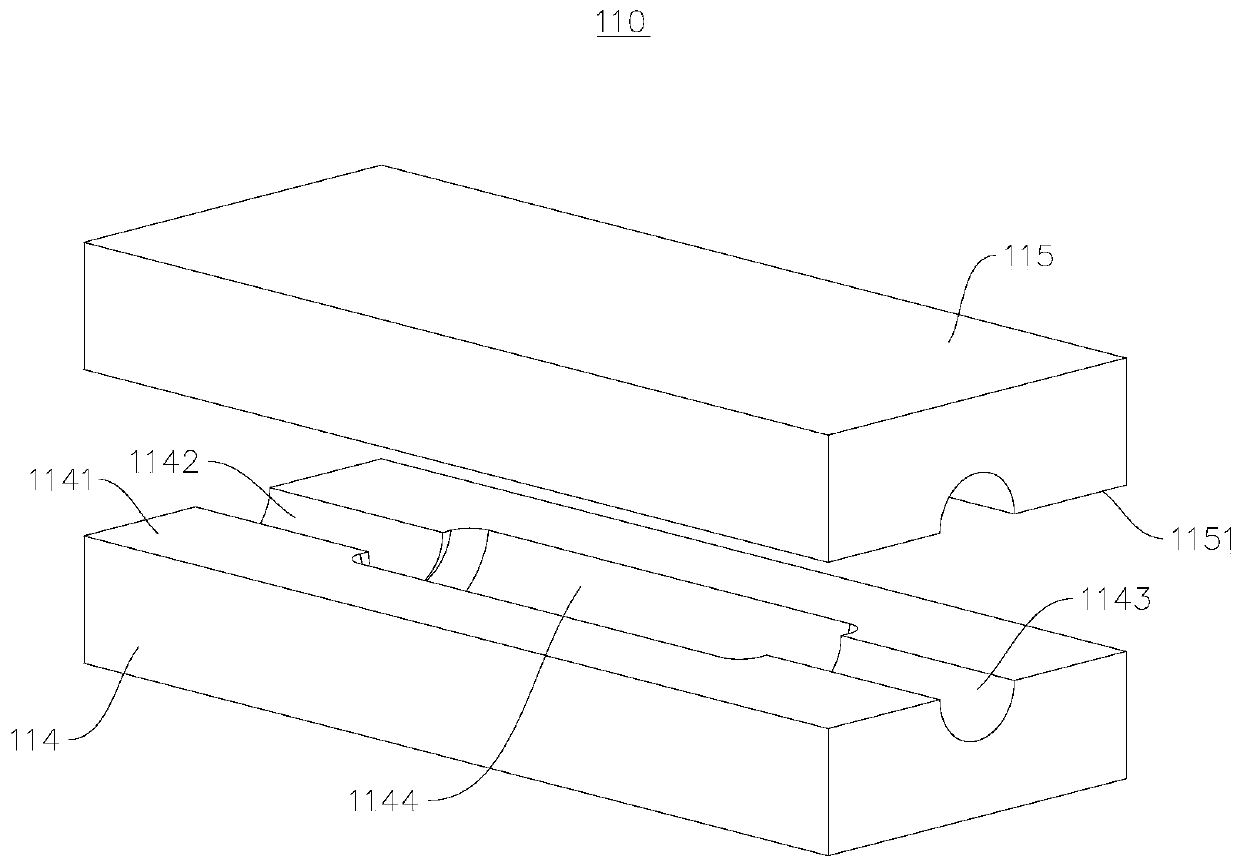

[0035] see figure 2 , the cooling housing 110 includes a cooling cavity 113, a first channel 111 and a second channel 112, the first channel 111 and the second channel 112 are respectively formed on both sides of the cooling cavity 113, the first channel 111 and the second channel 112 are connected with the cooling The cavity 113 communicates.

[0036] see i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com