Flexible metal pipeline wiring construction method

A flexible and metal technology, applied in cable laying equipment and other directions, can solve the problems of difficult construction, high rework rate of laying, long construction time, etc., to shorten the construction date, save the laying cost, and improve the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

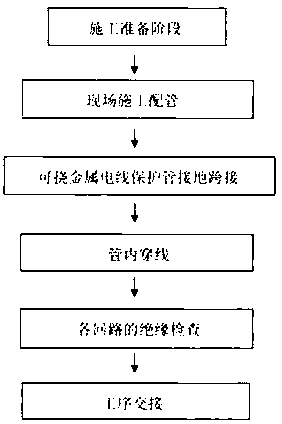

[0045] A flexible metal pipeline wiring construction method according to the present invention has a construction process as follows: construction preparation stage, on-site construction and piping, flexible metal wire protection pipe grounding jumper, threading in the pipe, insulation inspection of each circuit, and process handover.

[0046] Further, the specific method of construction is:

[0047] The construction preparation method is: check whether the inner and outer layers of the flexible metal wire protection tube are damaged, the certificate of conformity, and the test report;

[0048] Select and intercept models according to drawing requirements and remove burrs;

[0049] The construction method of on-site construction piping is as follows: pipe piping according to the drawings, the flexible metal wire protection pipe should be in a reasonabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com