Oil-based enhanced fog seal material for asphalt pavement, preparation method and construction method

A fog-sealing layer material and asphalt pavement technology, which is applied to building thermal insulation materials, roads, roads, etc., can solve the problem that the adhesion between the original fog-sealing layer and the original pavement stone cannot achieve the expected effect, and reduce the anti-slip ability of the asphalt pavement surface layer. , the reduction of the anti-seepage capacity of the pavement, etc., to achieve the effect of improving the anti-seepage capacity of the pavement, delaying UV aging, and improving the firmness of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

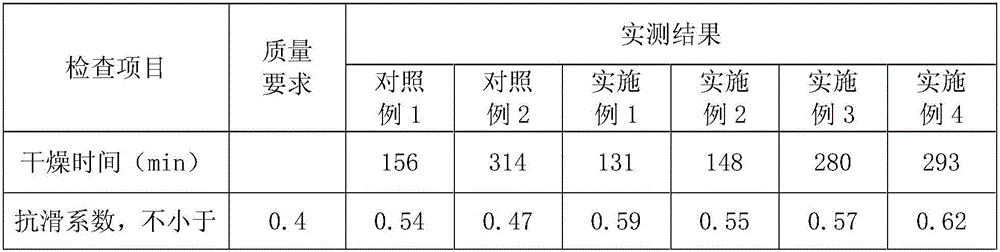

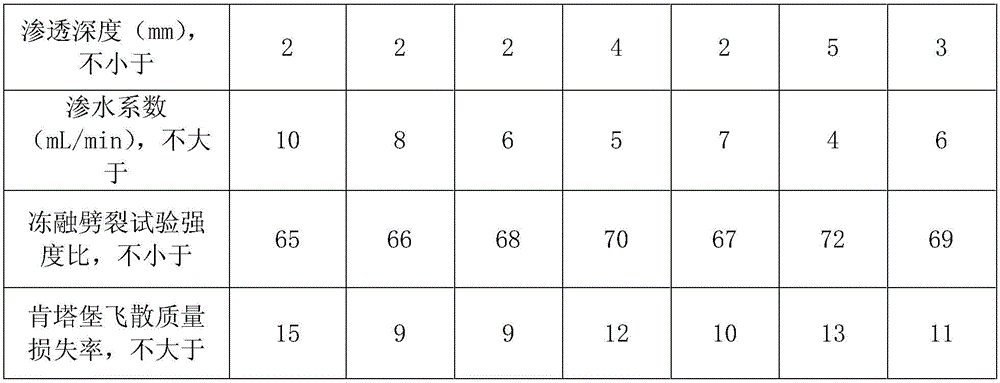

Examples

Embodiment 1

[0056] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0057] (1) Weigh each component:

[0058] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 50 parts of 90# asphalt, 20 parts of D-80 kerosene mineral spirits, 1 part of Reynolds peak, 2 parts of modified latex, and 2 parts of styrene butadiene particles.

[0059] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 50 parts of 90# asphalt, 20 parts of D-80 kerosene solvent oil, 1 part of Reynolds peak, 5 parts of modified latex, and 2 parts of styrene butadiene particles , 2 parts of phenyl salicylate.

[0060] (2) The preparation method of oily mist seal layer emulsion material:

[0061] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then mix it...

Embodiment 2

[0070] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0071] (1) Weigh each component:

[0072] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 70 parts of 70# asphalt, 60 parts of S-100 kerosene solvent oil, 10 parts of Reynolds peak, 8 parts of silane coupling agent KH7928, and 8 parts of modified rubber powder.

[0073] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 70 parts of 70# asphalt, 60 parts of S-100 kerosene solvent oil, 10 parts of Reynolds peak, silane coupling agent KH7928 parts, 4 parts of modified rubber powder, Benzophenone - 31 parts.

[0074] (2) The preparation method of oily mist seal layer emulsion material:

[0075] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then m...

Embodiment 3

[0084] Take the preparation of an oily enhanced fog seal material for asphalt pavement as an example for illustration.

[0085] (1) Weigh each component:

[0086] The sub-layer emulsion material for waterproof penetration includes the following components in parts by weight: 60 parts of 90# asphalt, 40 parts of S-100 solvent oil, 8 parts of Reynolds peak, 10 parts of silane coupling agent KH5500, and 6 parts of rock asphalt.

[0087] The anti-slip and wear-resistant upper sub-layer emulsion material includes the following components in parts by weight: 60 parts of 90# asphalt, 40 parts of S-100 solvent oil, 5 parts of Reynolds peak, 15 parts of silane coupling agent KH55015 parts, 3 parts of rock asphalt, salicylic acid 2 parts of phenyl ester.

[0088] (2) The preparation method of oily mist seal layer emulsion material:

[0089] The preparation method of the waterproof permeable lower sub-layer emulsion material: first heat and melt the petroleum asphalt, then mix it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com