Locating mounting method for rudder carrier base on ship

A positioning installation and rudder bearing technology, which is applied to ship parts, ship construction, transportation and packaging, etc., can solve the problems of difficulty in guaranteeing processing quality, troublesome machining work, and large interference in three-dimensional operations, so as to reduce the application of special equipment , Improve accuracy and efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

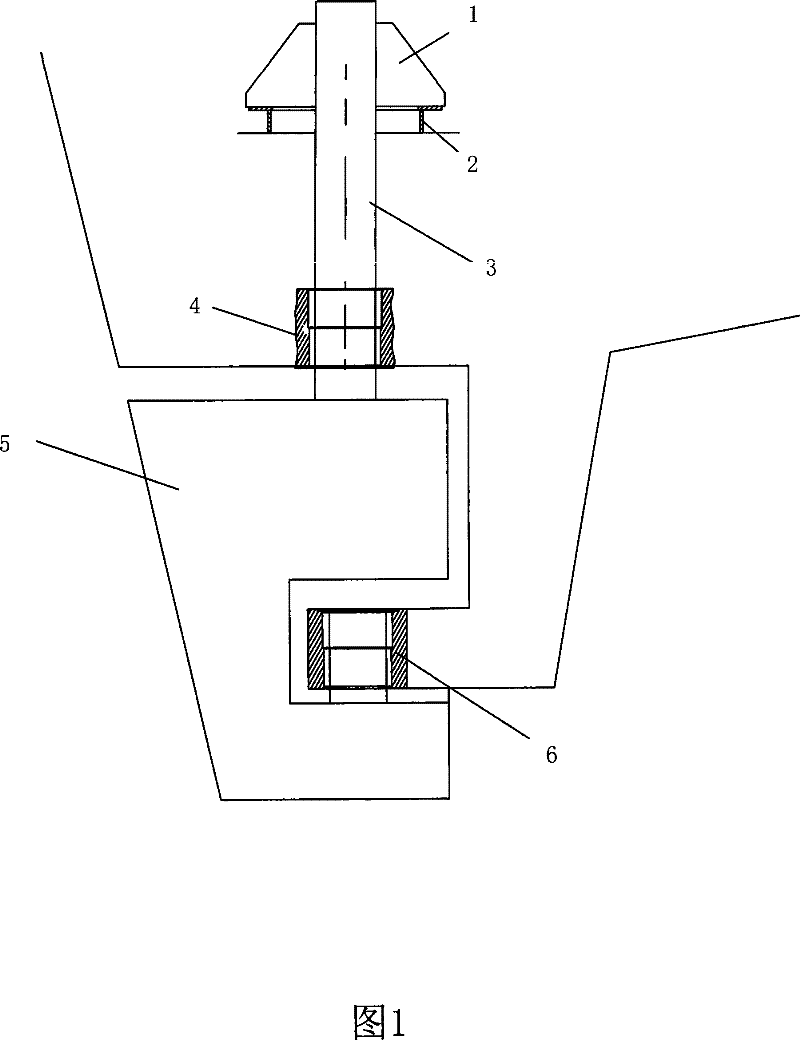

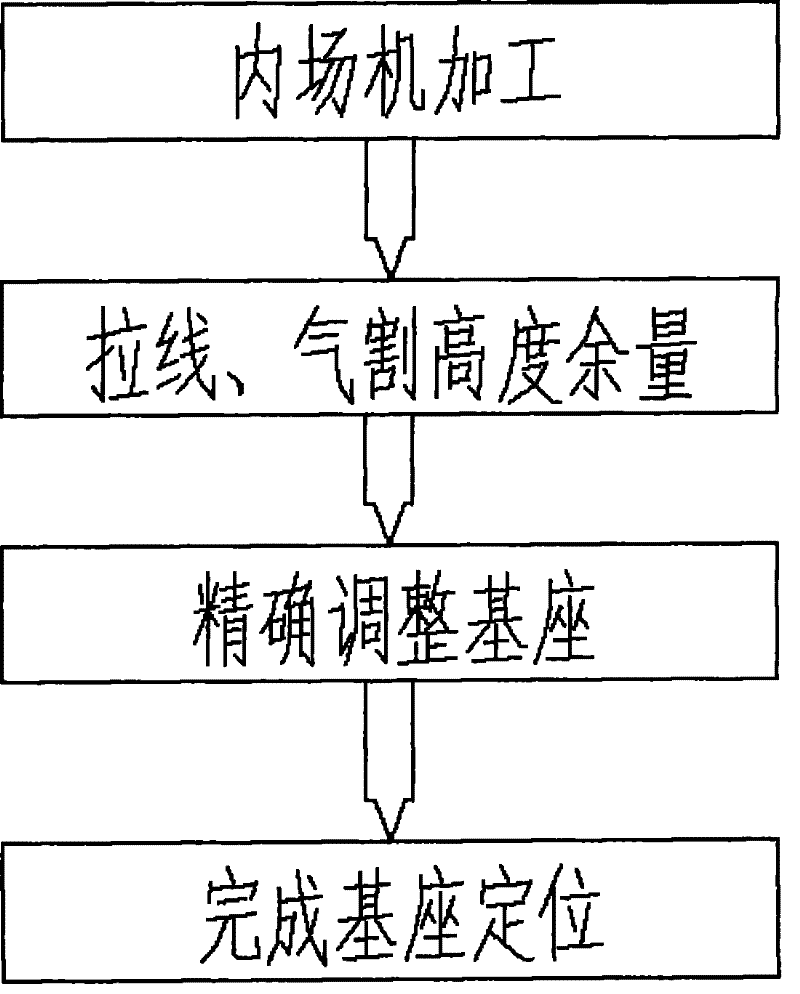

[0028] The following takes the positioning and installation of the upper rudder support base on a 74500-ton bulk carrier as an example to demonstrate the specific application of the method of the present invention. Please refer to the brief flow diagram image 3 .

[0029] A method for installing and positioning an upper rudder support base on a 74,500-ton bulk carrier, the method includes the following steps:

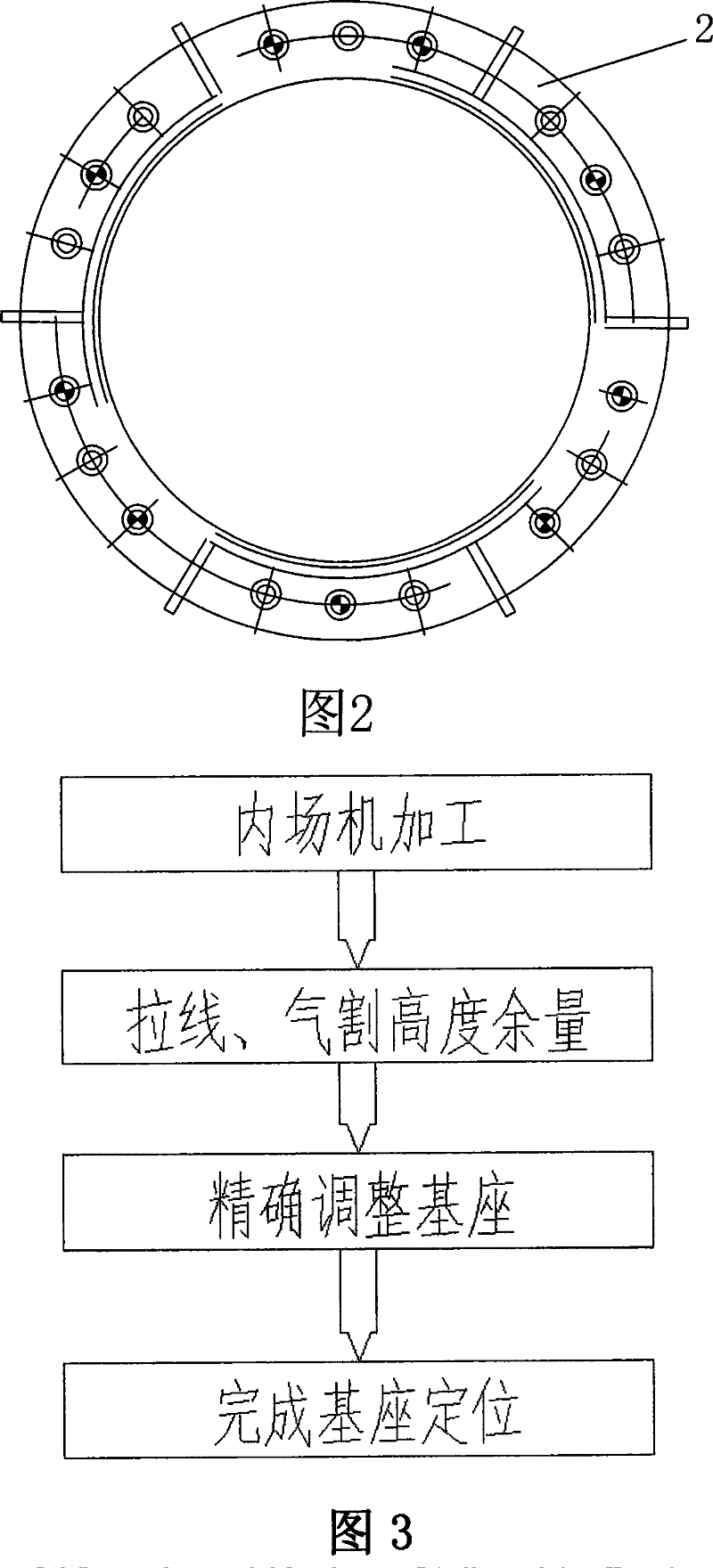

[0030] ①Complete the machining of the upper rudder bearing base 2, the rudder stock bearing housing 4 and the rudder pin bearing housing 6 in the workshop, and reserve the height margin of the upper rudder bearing base 2 for removal after precision adjustment during the installation process, Wherein the machined part of the upper rudder bearing base 2 comprises the upper surface and the inner circular surface of the upper rudder bearing base, the machined part of the rudder stock bearing seat 4 is the inner circular surface, and the machined part of the rudder pin bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com