A kind of coating method of traditional Chinese medicine pellet

A technology for traditional Chinese medicine and pellets, applied in the field of coating of traditional Chinese medicine pellets, can solve the problems of reducing the spraying speed of coating liquid, unstable physical and chemical properties, collapsed bed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

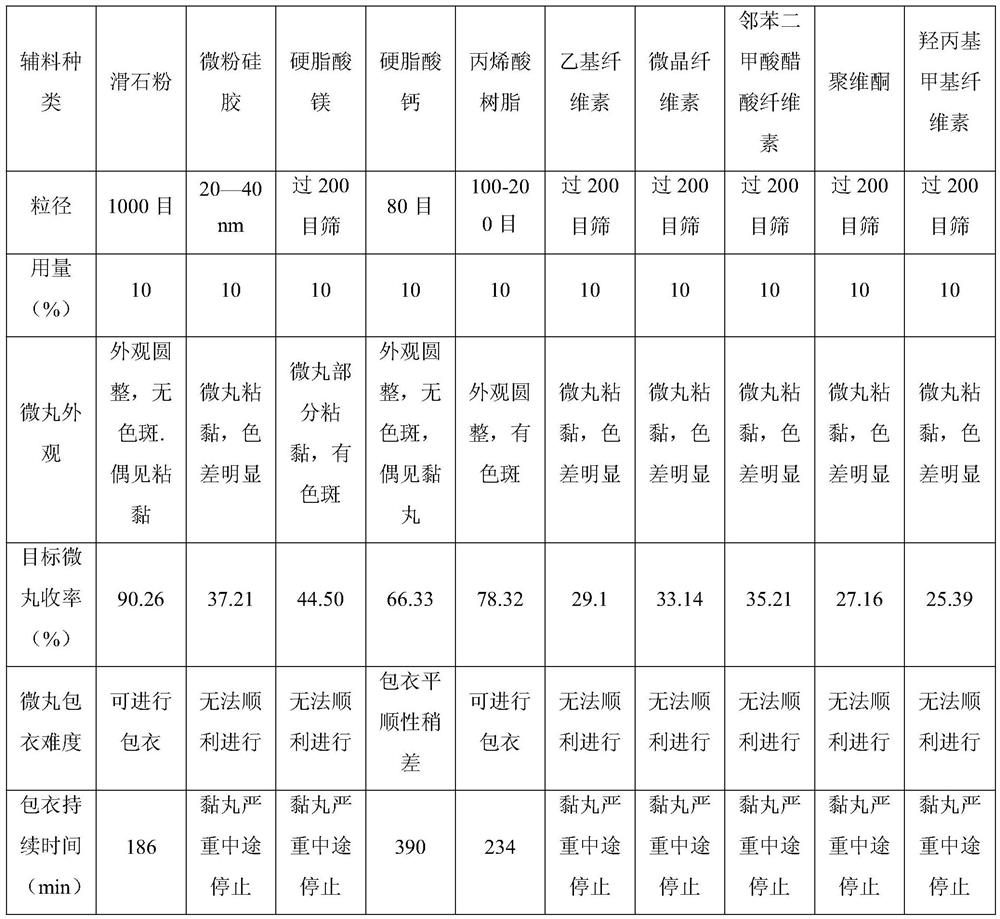

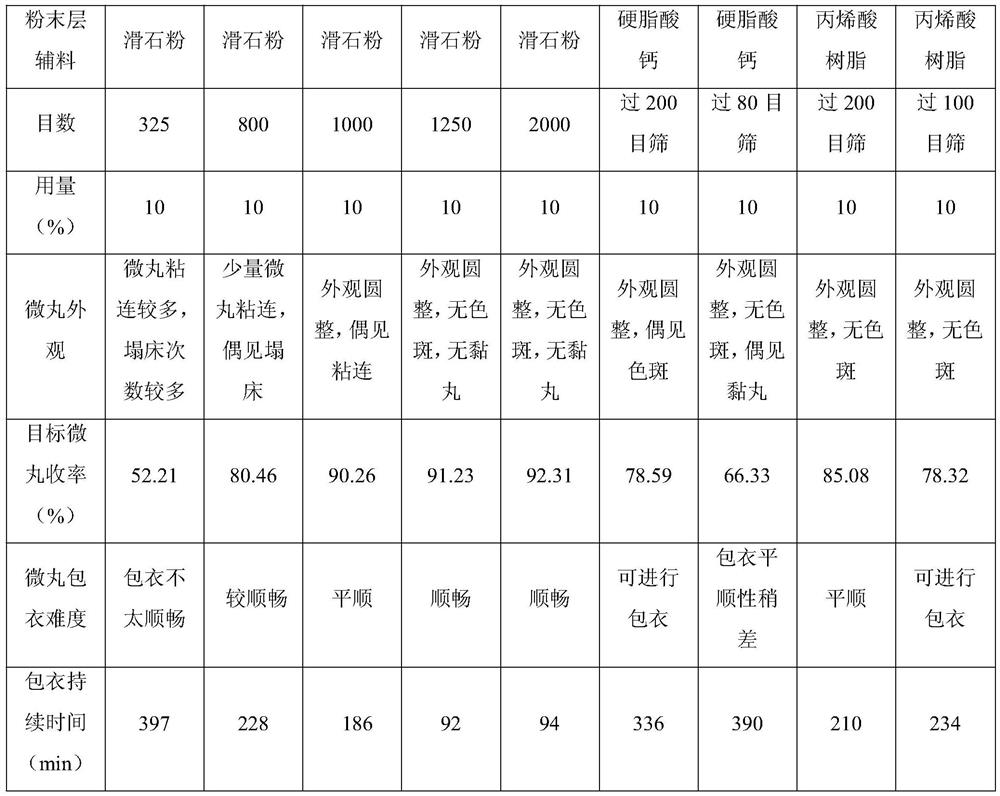

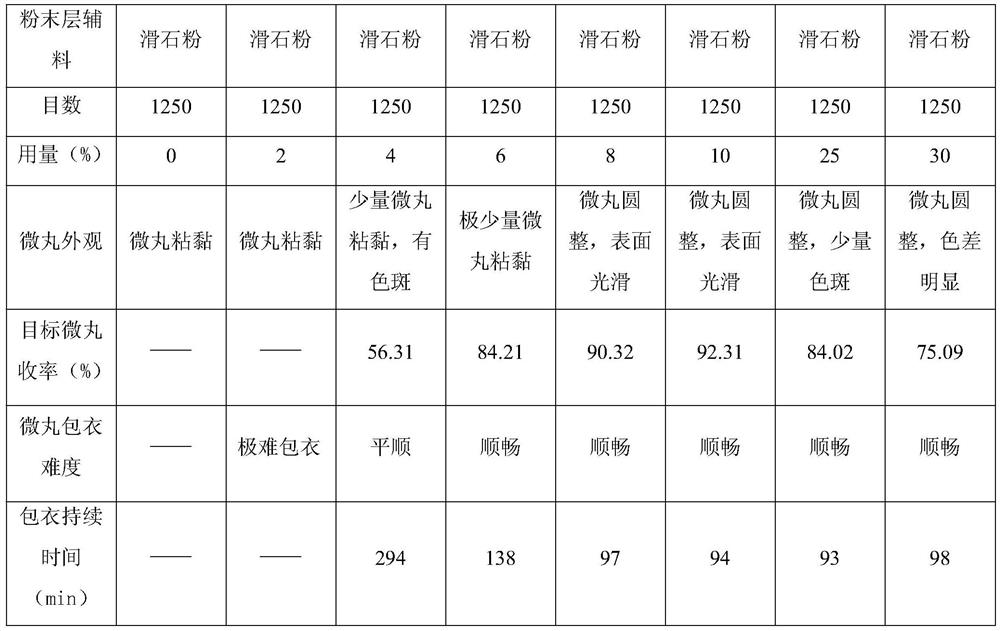

Method used

Image

Examples

Embodiment 1

[0073] Preparation of Acanthopanax acanthopanax extract: the medicinal material of Acanthopanax senticosus (collected from Yichun District, Yichun City, Heilongjiang Province, identified as Acanthopanax senticosus by Professor Song Liangke of Southwest Jiaotong University, Latin name: ACANTHOPANACIS SENTICOSI RADIX ETRHIZOMA SEU CAULIS) was pulverized into Granules, add 8 times the amount of 28% ethanol, heat to boiling, extract twice, each time for 1 hour, and combine the extracts; combine and concentrate under reduced pressure to a relative density of 1.18-1.20g / ml to obtain an extract; Dried extract powder, set aside.

[0074] Preparation of ball core: take an appropriate amount of cornstarch and pass through a 200-mesh sieve; weigh 2% (relative to the amount of cornstarch) hydroxypropyl methylcellulose E5 as a binder, add water to make a 1% binder solution Get a part of the starch and put it into a centrifugal granulator (Chongqing Yingge multifunctional centrifugal granul...

Embodiment 2

[0080] Preparation of Acanthopanax acanthopanax extract: the medicinal material of Acanthopanax senticosus (collected from Yichun District, Yichun City, Heilongjiang Province, identified as Acanthopanax senticosus by Professor Song Liangke of Southwest Jiaotong University, Latin name: ACANTHOPANACIS SENTICOSI RADIX ETRHIZOMA SEU CAULIS) was pulverized into Granules, add 8 times the amount of 30% ethanol, heat to boiling, extract twice, each time for 1 hour, and combine the extracts; combine and concentrate under reduced pressure to a relative density of 1.18-1.20g / ml to obtain an extract; Dried extract powder, set aside.

[0081] The preparation of ball core: take appropriate amount of lactose, sieve 200 orders; Take by weighing 3% (relative to the amount of lactose) hydroxypropyl methylcellulose E5 as binder, add water and be made into 1% binder solution; Take A part of lactose is put into the centrifugal granulator, and the binder is sprayed into the silo from the nozzle of ...

Embodiment 3

[0087] Preparation of Acanthopanax extract: take Acanthopanax medicinal material (collected from Tieli District, Yichun City, Heilongjiang Province, identified as Acanthopanax, a traditional Chinese medicine by Professor Song Liangke of Southwest Jiaotong University, Latin name: ACANTHOPANACIS SENTICOSI RADIX ETRHIZOMA SEU CAULIS), and Break it into 5mm particles, add 8 times the amount of deionized water, heat to 80°C, extract 4 times, each time for 1.5 hours, and combine the extracts; the combined solution is concentrated under reduced pressure to a relative density of 1.18-1.20g / ml to obtain an extract; The extract liquid is dried to obtain extract powder, which is set aside.

[0088] Preparation of pellet cores: use commercially available microcrystalline cellulose blank pellet cores (Asahi Kasei Co., Ltd., Japan), with a particle size of 750 μm-850 μm.

[0089] Preparation of Acanthopanax senticosus pellets: (1) Gradually add Acanthopanax senticosus extract extract powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com