Novel spray cabinet for wine bottle spraying system

A new type of wine bottle technology, applied in spray booths, spray devices, etc., can solve the problems of disordered paint mist sprayed by spray guns, affecting spraying effect, and poor exhaust effect, so as to improve exhaust effect and reduce turbulent flow , The effect of improving the exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] This embodiment provides a new type of spray booth used in the wine bottle spraying system. Compared with the prior art, the spray booth has a simple structure, good exhaust effect, and can effectively improve the spraying quality.

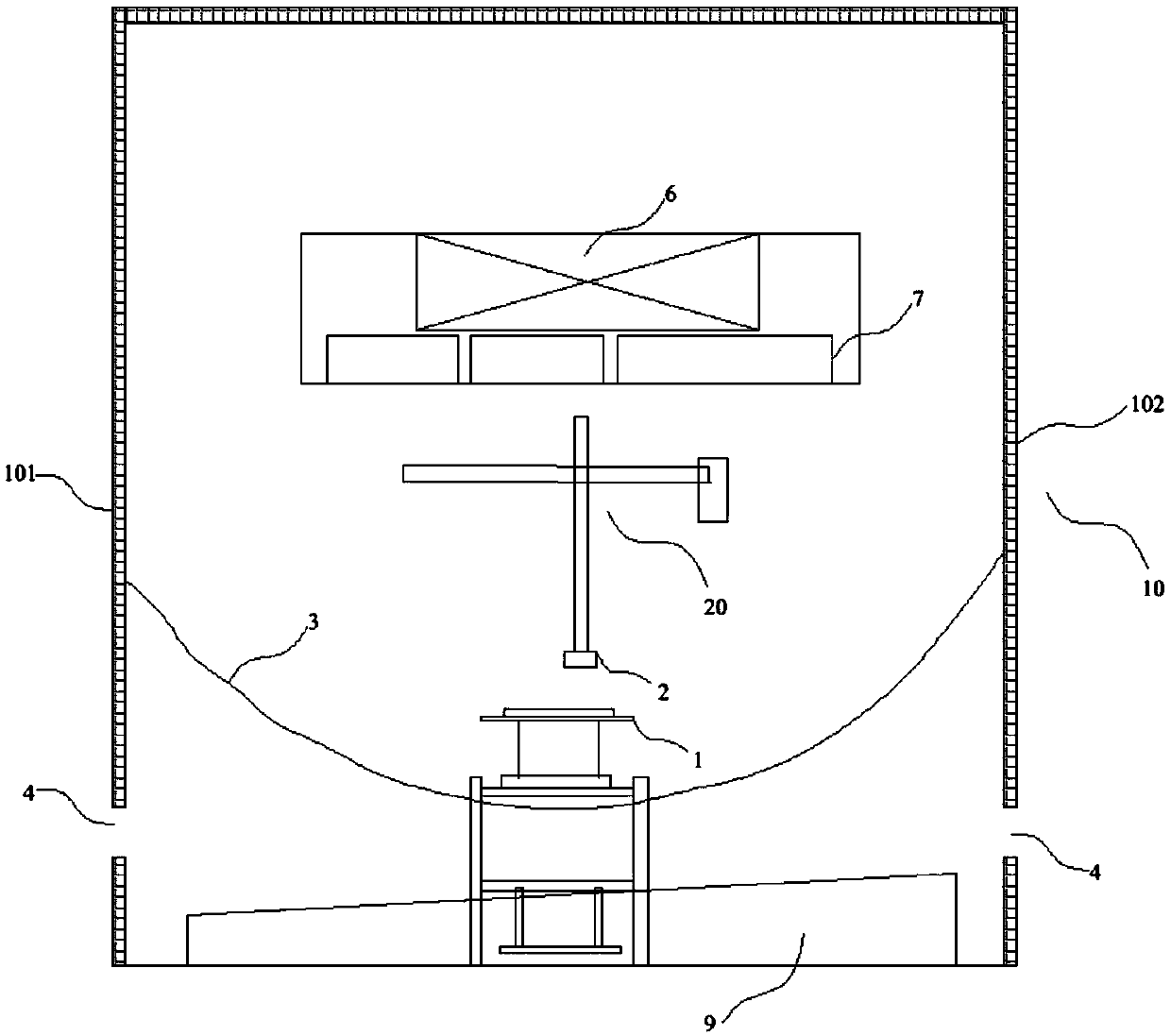

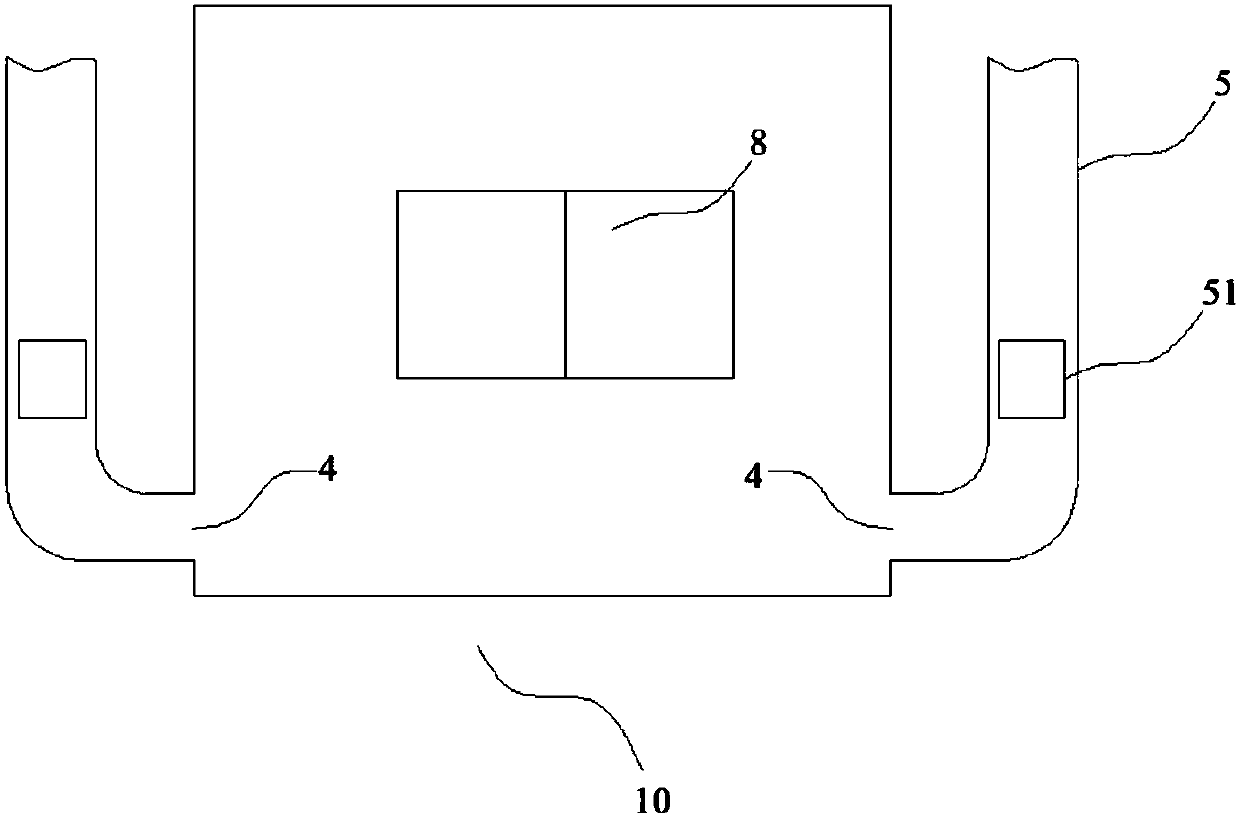

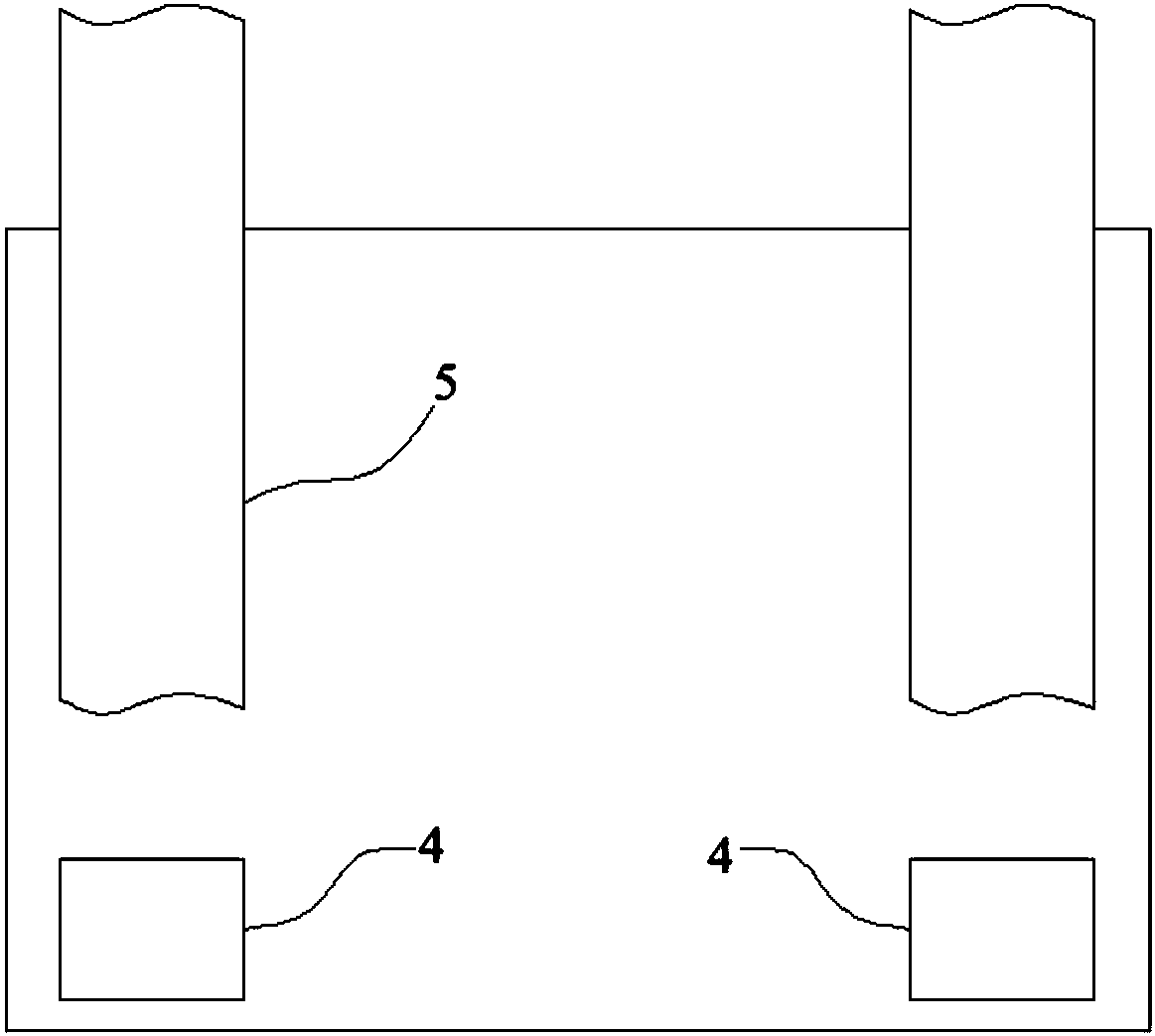

[0029] Specifically, see Figure 1 to Figure 3 ,in figure 1 It is a perspective view of a novel spray cabinet for a wine bottle spray system of the present embodiment; figure 2 It is a front view of a novel spray cabinet for a wine bottle spray system of the present embodiment; image 3 It is a side view of a new type of spray booth used in the wine bottle spray system of this embodiment.

[0030] As can be seen from the figure, the spray booth 10 of this embodiment is arranged in the painting room, and the automatic spray equipment 20 is arranged in the spray booth 10, and the automatic spray equipment 20 includes a spray gun bracket and a spray gun 2 connected to the end of the spray gun bracket. A conveying line 1 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com