Starch extruder

An extruder and starch technology, applied in the field of extrusion equipment, can solve problems such as uneven extrusion weight and poor extrusion stability, and achieve the effect of stable performance and the same weight of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

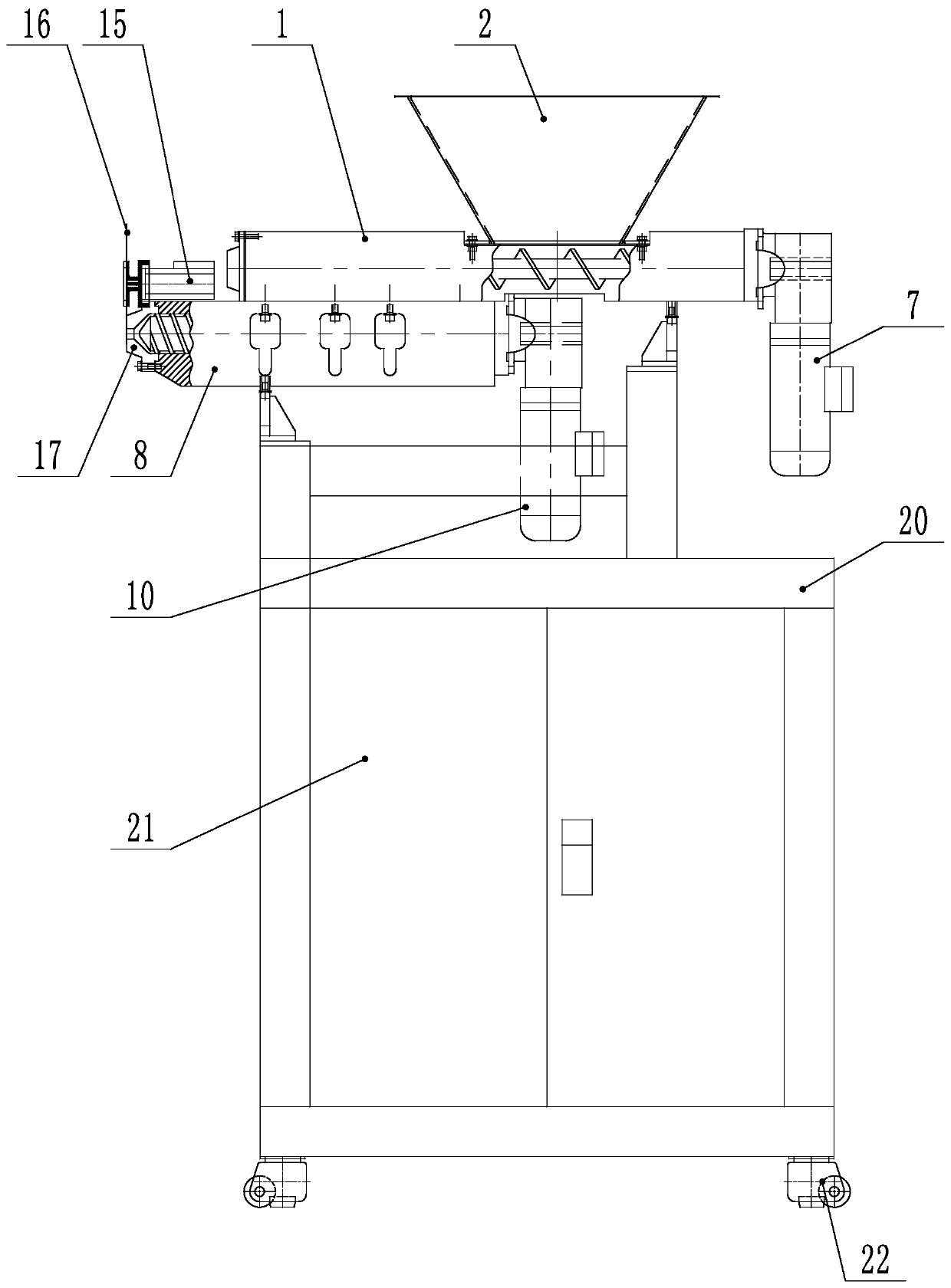

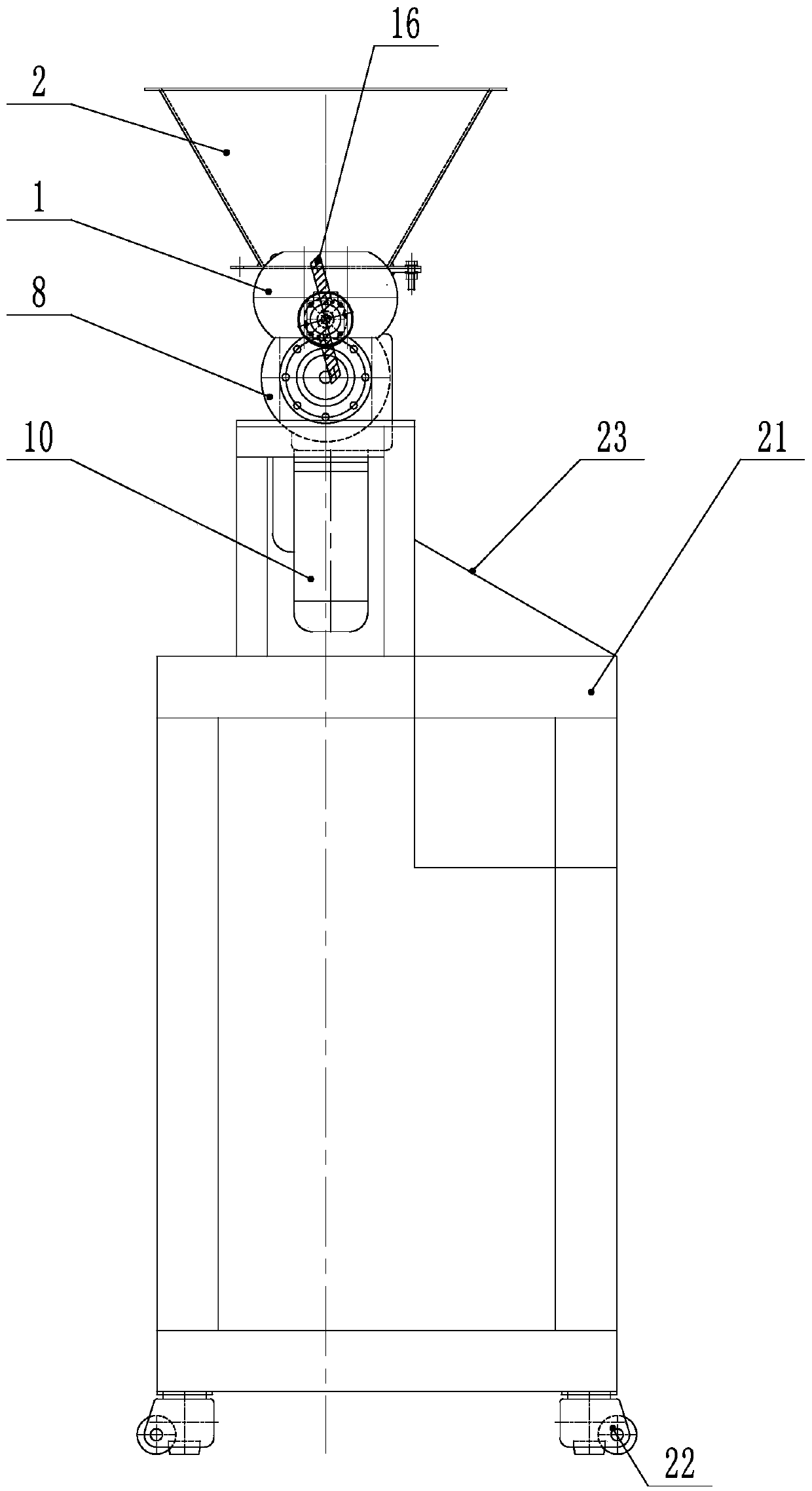

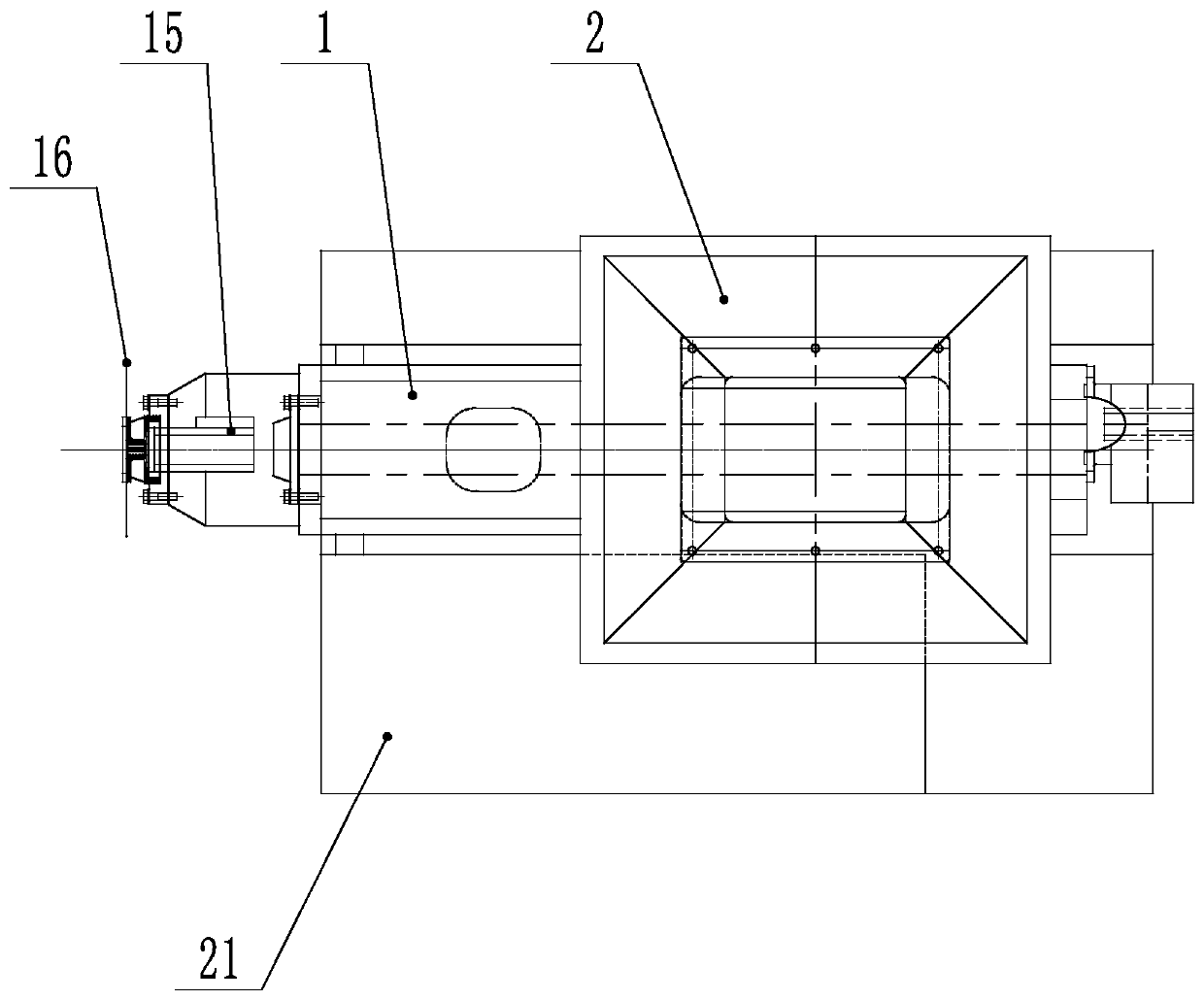

[0025] The present invention will be further described below with specific embodiment, see figure 1 -5:

[0026] A kind of starch extruder, comprises feeding double machine barrel 1 and is arranged on the feeding hopper 2 at the feed inlet place of feeding double machine barrel 1, is provided with the first screw rod 3 and the second in feeding double machine barrel 1 Two screw rods 4, the first screw rod 3 and the second screw rod 4 all have the first helical groove 5 and the second helical groove 6 of the double helix form, the helical direction of the first helical groove 5 and the second helical groove 6 is opposite, two screw rods The axes of the two screws are set in parallel, and the corresponding parts of the spiral grooves on the two screws are mirrored. One screw 3 is driven to rotate by the feeding motor 7, and the second screw 4 is driven to rotate by the transmission mechanism. The first screw 3 and the second screw 4 rotate in opposite directions. Internal rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com