Automatic packaging machine for tea processing

An automatic packaging machine, packaging machine technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve problems such as the degree of automation to be improved, imperfect functions, etc., to achieve fast and convenient feeding and discharging, high work efficiency, and the same weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

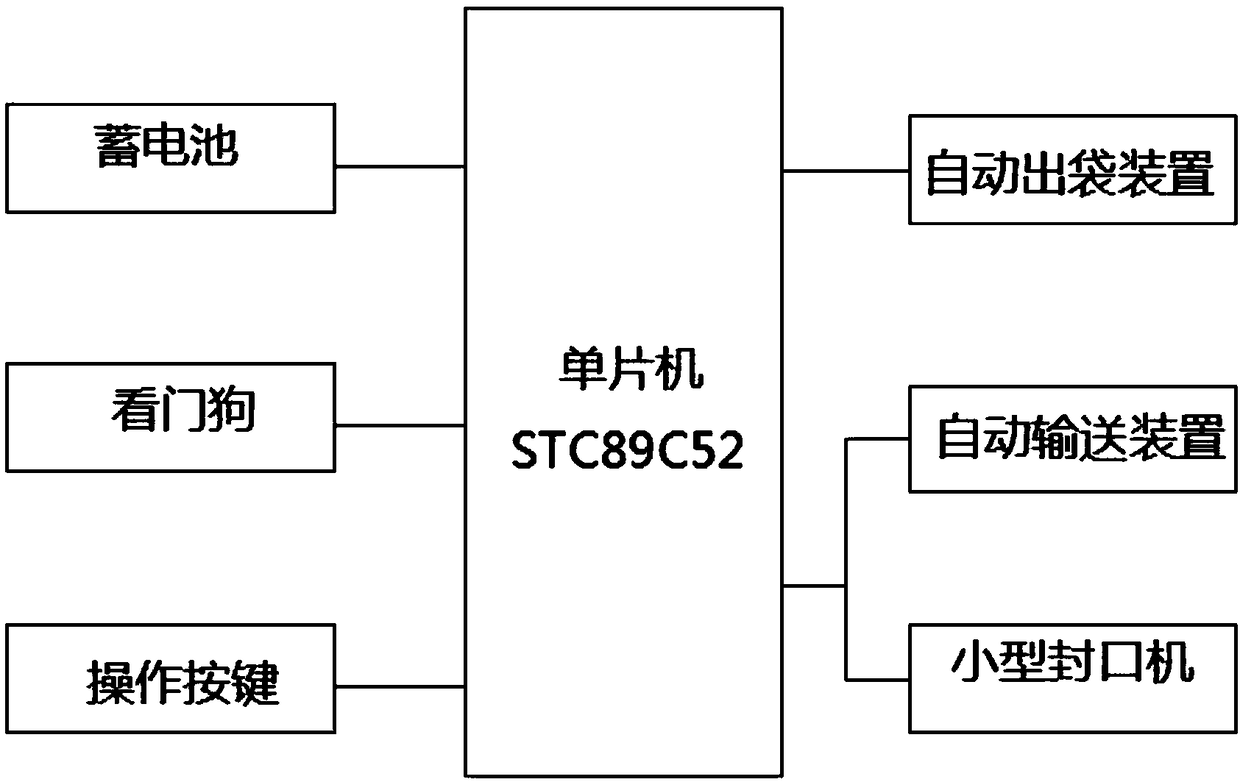

[0020] Embodiment 2, on the basis of Embodiment 1, this design adopts the controller 7 to control the action of each electric load, the controller 7 is as image 3 As shown, the single-chip microcomputer is used to coordinate and control the actions of each component, and it can also be operated manually through the control buttons.

Embodiment 3

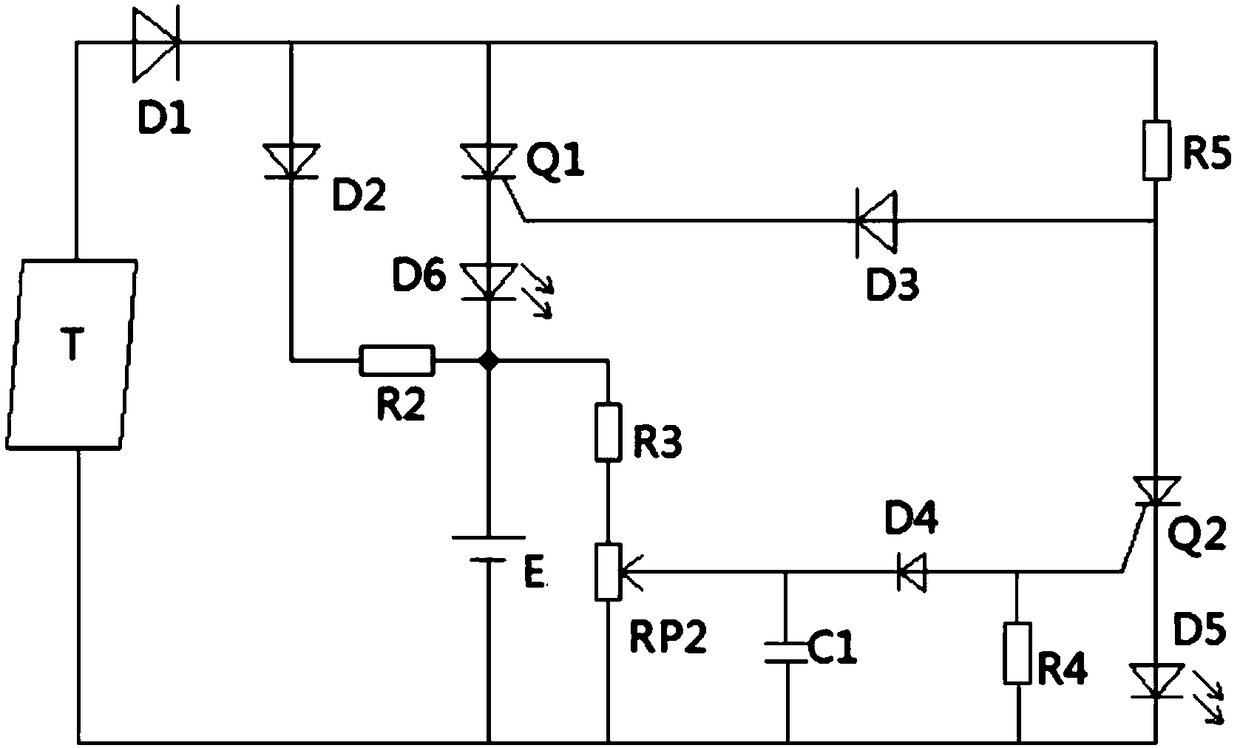

[0021] Embodiment 3: On the basis of Embodiment 1, this design adopts solar panels 25 to supply power to save energy, such as image 3 As shown, when there is sufficient sunlight during the day, the solar panel T completes the photoelectric conversion and supplies power to the circuit through the diode D1, and the subsequent circuit is powered. When the voltage of the battery E to be charged is low, after the voltage is divided by the resistor R3 and the potentiometer RP2 The voltage is not enough to meet the conduction of the diode D3, so the one-way thyristor Q2 is cut off, and the voltage output from the emitter of the triode V1 is added to the control pole of the one-way thyristor Q1 through the resistor R5 and the diode D3 to make it conduct, and the battery E High-power charging, at this time, the light-emitting diode D6 lights up as a high-current charging indicator. As the charging progresses, the voltage of E continues to rise. When E is fully charged, the voltage divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com