Making mold for coarse food grain flour meat pies

A technology of coarse grains and pies, which is applied to dough forming machinery or equipment, dough processing, baking, etc., to improve the taste, make the dough crispy and delicious, and increase the intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

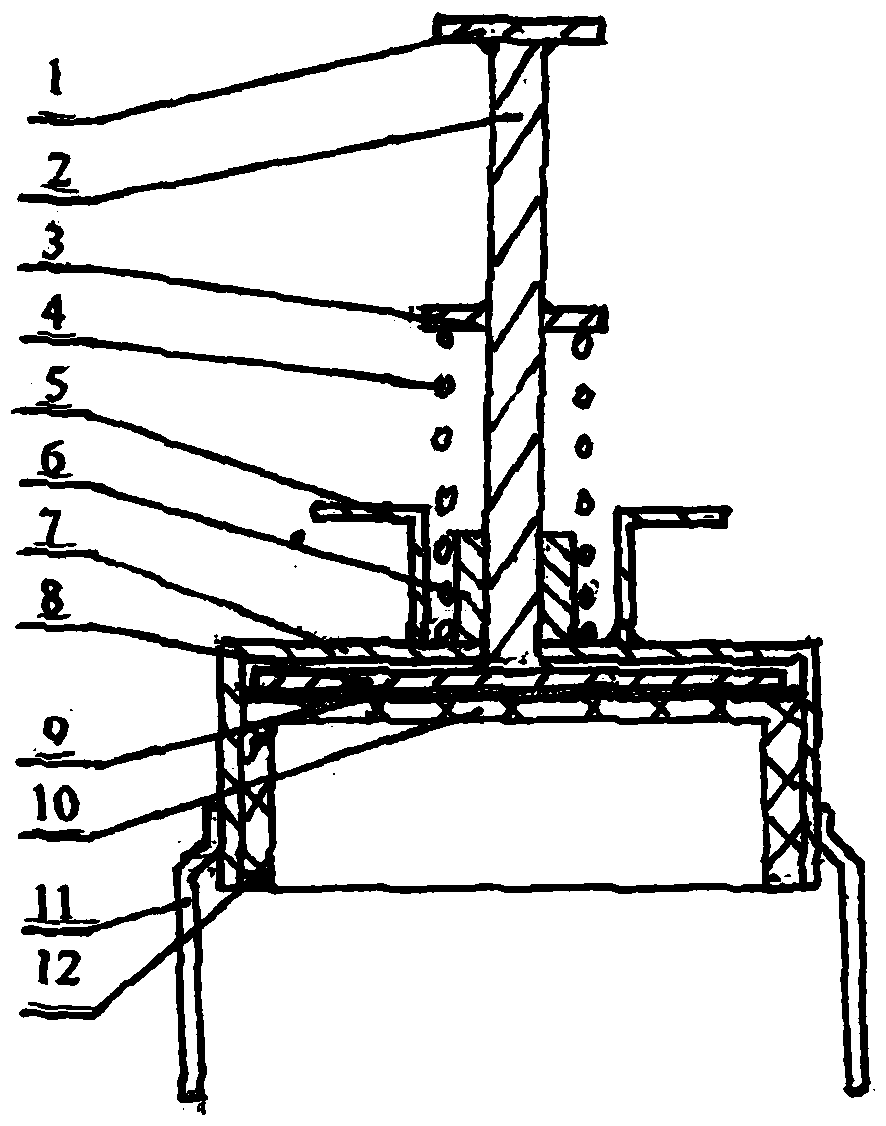

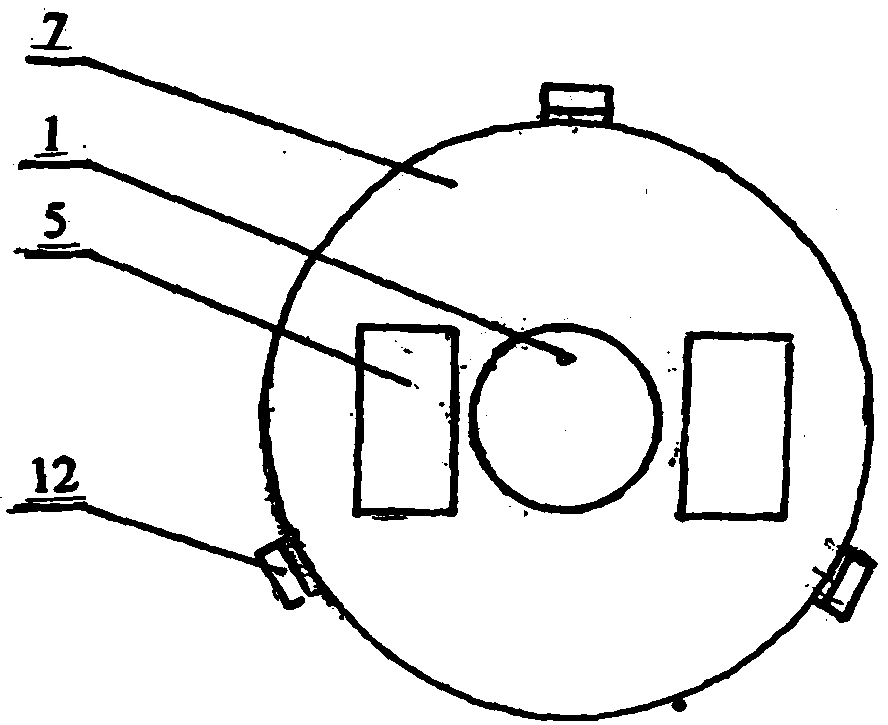

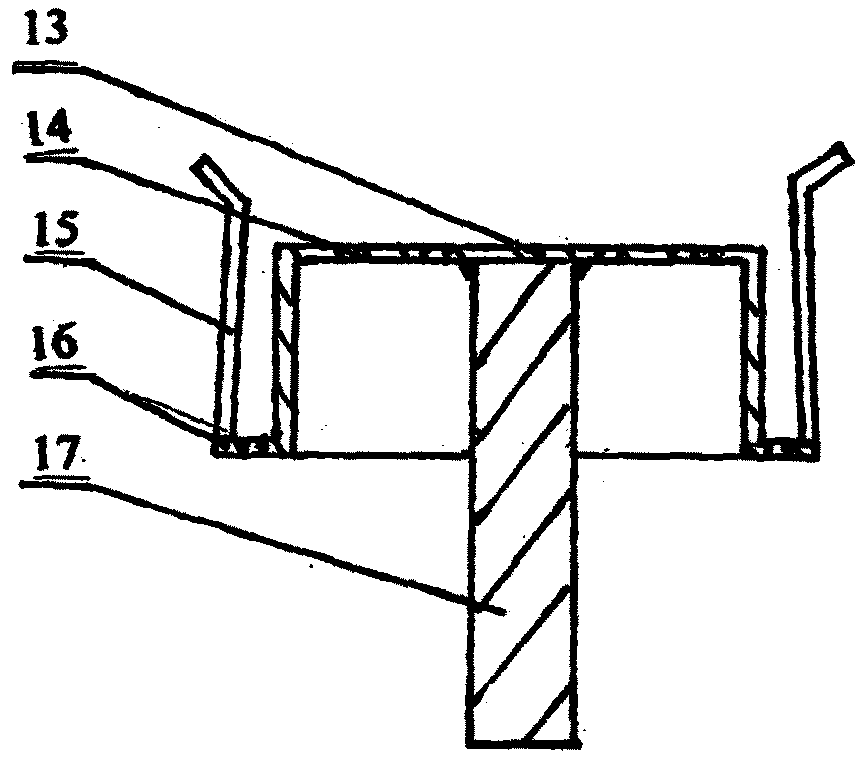

[0006] Specific implementation mode one: (see Figure 1 to Figure 14 ) This embodiment includes a pressing plate 1, a push rod 2, a spring pressing plate 3, a spring 4, a clasp 5, a push rod cover 6, a forming mold body 7, a mold ejecting top plate 8, a wet drawer cloth 9, coarse grain flour mud 10, and an ejecting mold Positioning plate 11, small column 12, pressing mold body 13, small hole 14, surrounding thickness positioning plate 15, bottom thickness positioning plate 16, handle 17, cake cover mold positioning plate 18, cake cover mold body 19, cake cover mold wet Drawer cloth 20, cake cover mold handle 21, filling mold body 22, filling mold positioning plate 23, filling material 24, filling material compaction mold handle 25, filling material compaction thickness positioning plate 26, filling material compaction mold body 27, punching mesh plate 28, conical head 29, octagonal shaft 30, front circular shaft 31, baking upper mold body 32, baking lower mold body 33, vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com