Unmanned-aerial-vehicle shock absorption gasbag and unmanned-aerial-vehicle gasbag shock absorption device

A shock-absorbing airbag and unmanned aerial vehicle technology, applied in the field of unmanned aerial vehicles, can solve the problems of large volume, low reliability, and poor control of the size of the vent hole, etc., to achieve small size, simple and reliable control, and avoid airbags The effect of insufficient or overcharge problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

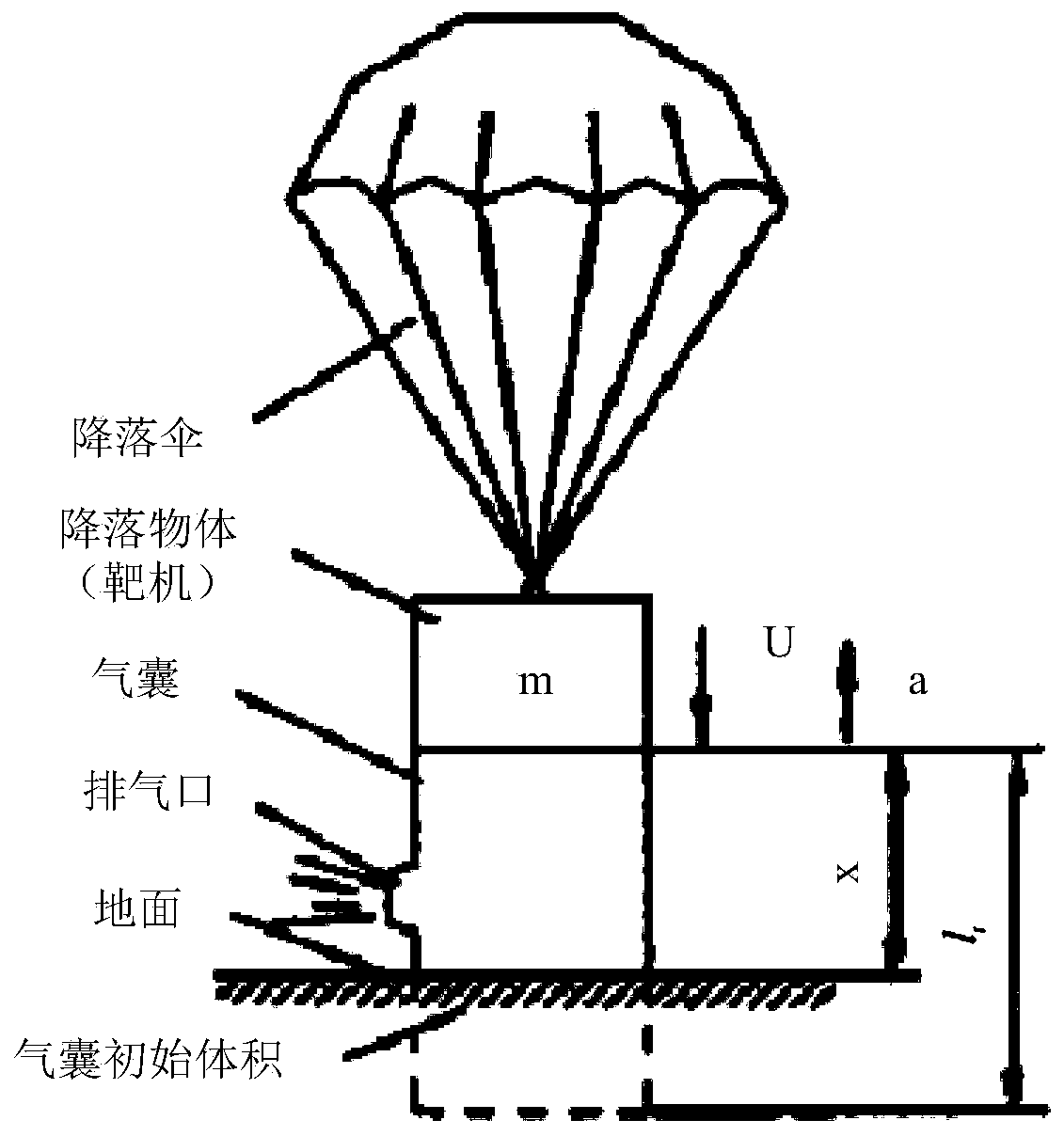

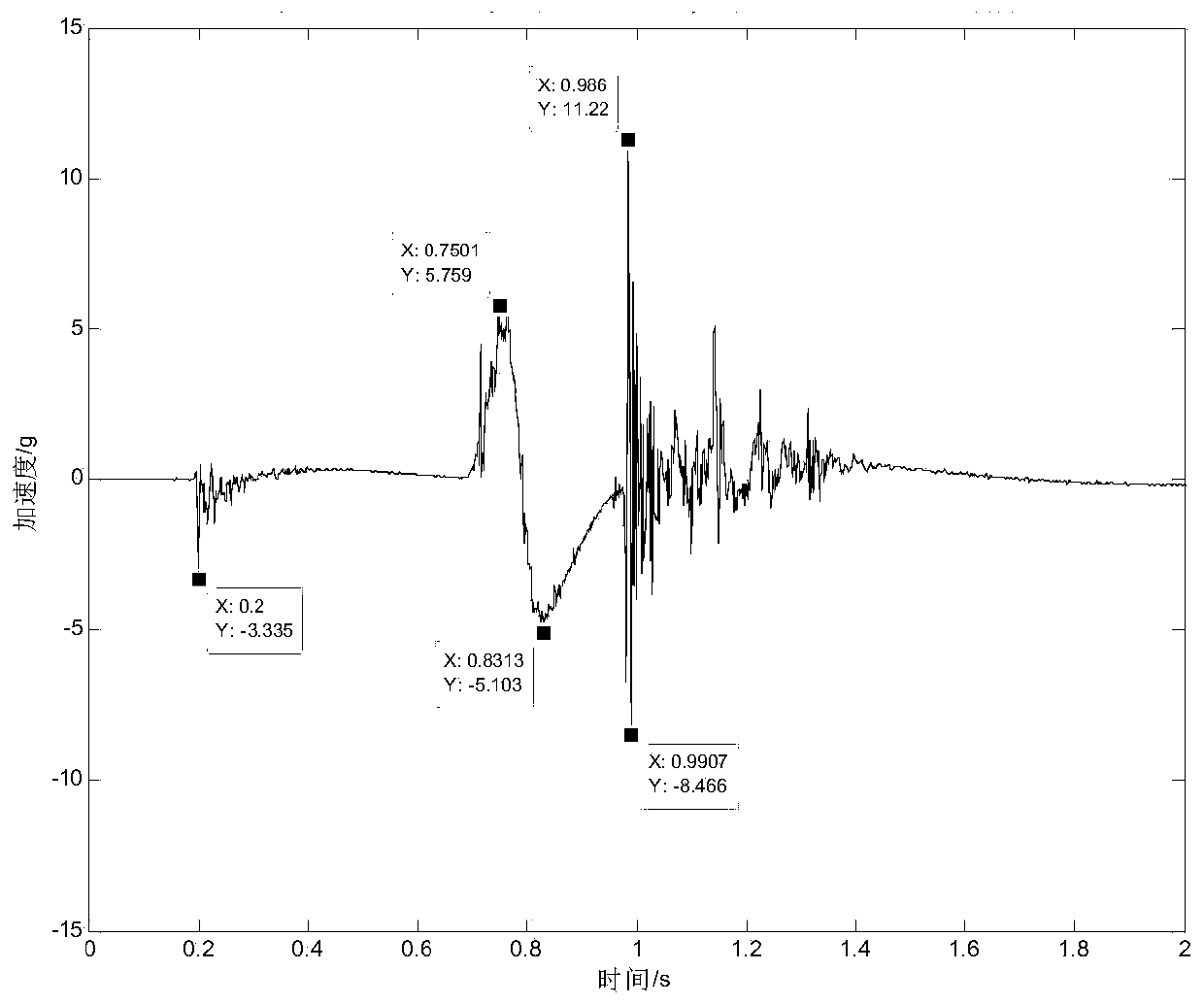

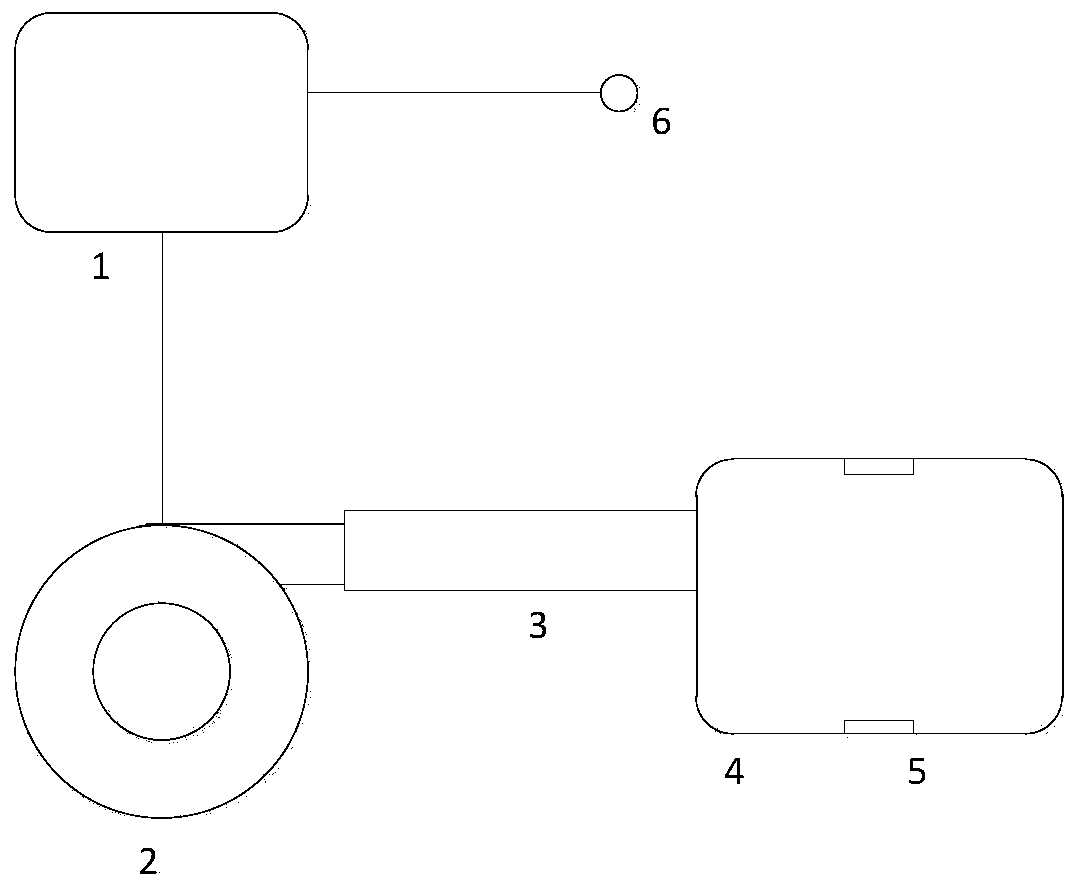

[0014] The airbag shock absorption process has the following stages: airbag inflation → ground contact compression (volume reduction, pressure inside the bag) → target drone deceleration → airbag pressure reaches the deflation pressure value (open the vent hole, the pressure inside the bag drops) → The target drone lands.

[0015] If there is a certain moment t during the landing process of the target machine, the speed of the target machine v(t)=0, and the pressure F(t) of the airbag on the target machine<G (the gravity of the target machine), the kinetic energy of the target machine is zero at this time, and the airbag The potential energy of the target machine is not enough to rebound the target machine, and if the maximum overload is less than the allowable overload of the target machine, the goal of airbag shock absorption is achieved.

[0016] Assuming that the target drone falls vertically, and the gas mass in the bag is ignored during the whole process, the velocity eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com