High-efficiency type rust removal liquid and use method thereof

A high-efficiency rust removal liquid technology, applied in the field of rust removal liquid, can solve problems such as environmental pollution, workpiece damage, and incomplete rust removal, and achieve the effects of strong hydrophilicity, tension reduction, and obvious rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

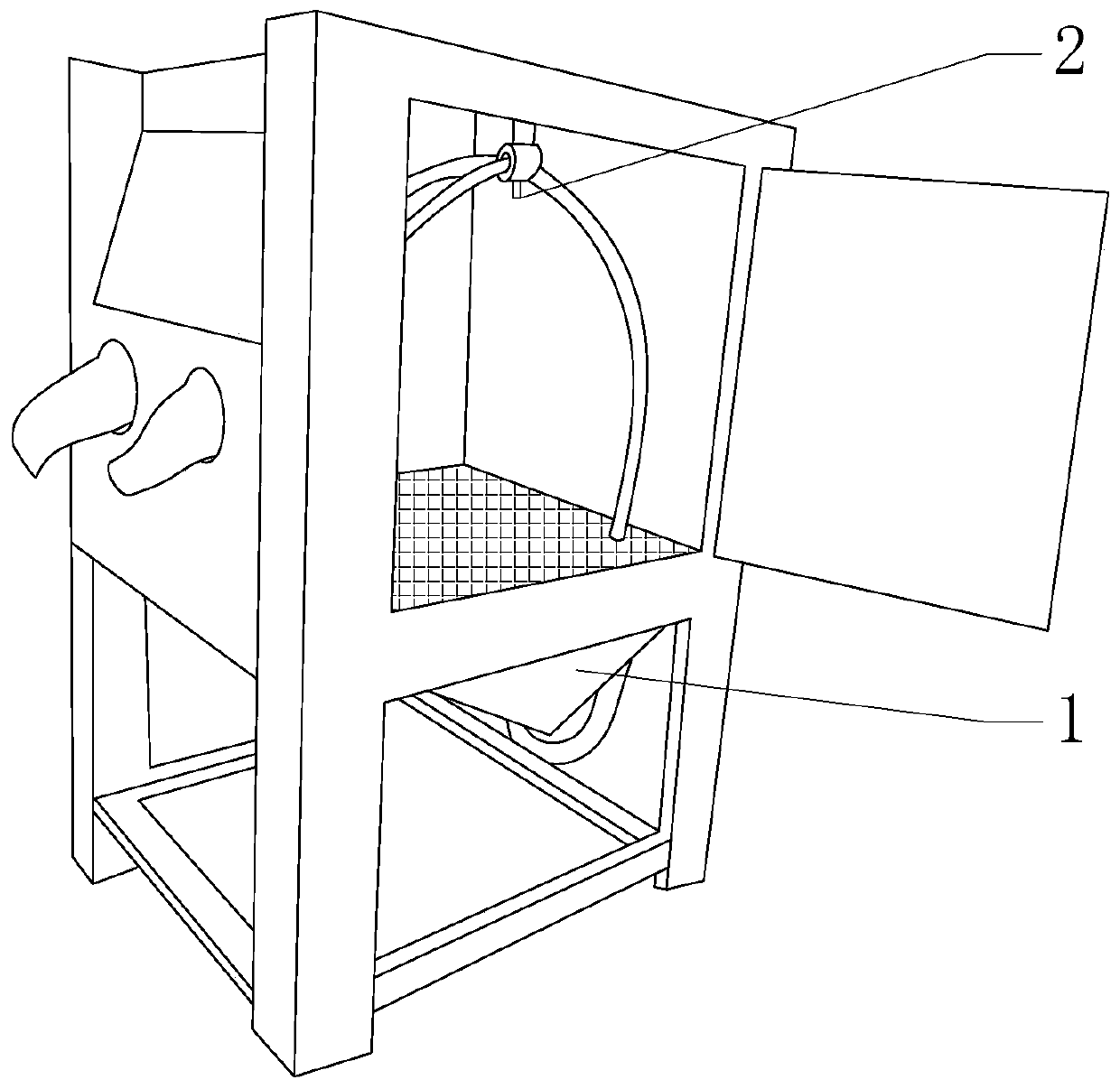

Image

Examples

Embodiment 1

[0034] The composition and ratio of the derusting liquid are 2kg of 60 mesh glass beads, 50g of washing powder, 2kg of antirust liquid and 50kg of water.

Embodiment 2

[0036] The composition and proportion of the antirust liquid are 13 parts of benzotriazole, 10 parts of sodium nitrite, 12 parts of sodium benzoate, 20 parts of sodium silicate, 13 parts of EDTA and 20 parts of sodium dodecylbenzenesulfonate.

[0037] Therefore, the present invention adopts the above-mentioned high-efficiency derusting liquid and its use method to quickly remove the dirt on the surface of the workpiece with little environmental pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com