Anti-hooking polyester-ammonia air layer fabric

An air layer and anti-snag technology, which is applied in the field of clothing fabrics, can solve the problems of affecting the appearance of clothing, reducing the performance of clothing, and affecting printing effects, etc., to achieve the effects of improving suitability and cost performance, improving work efficiency, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

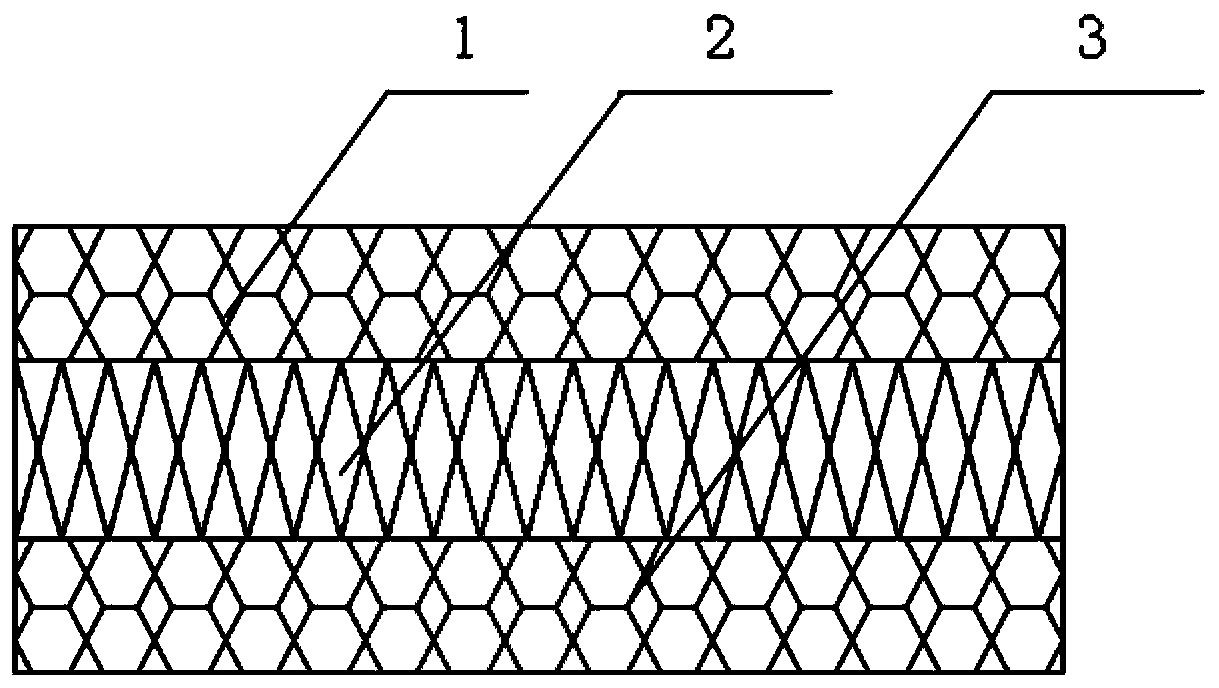

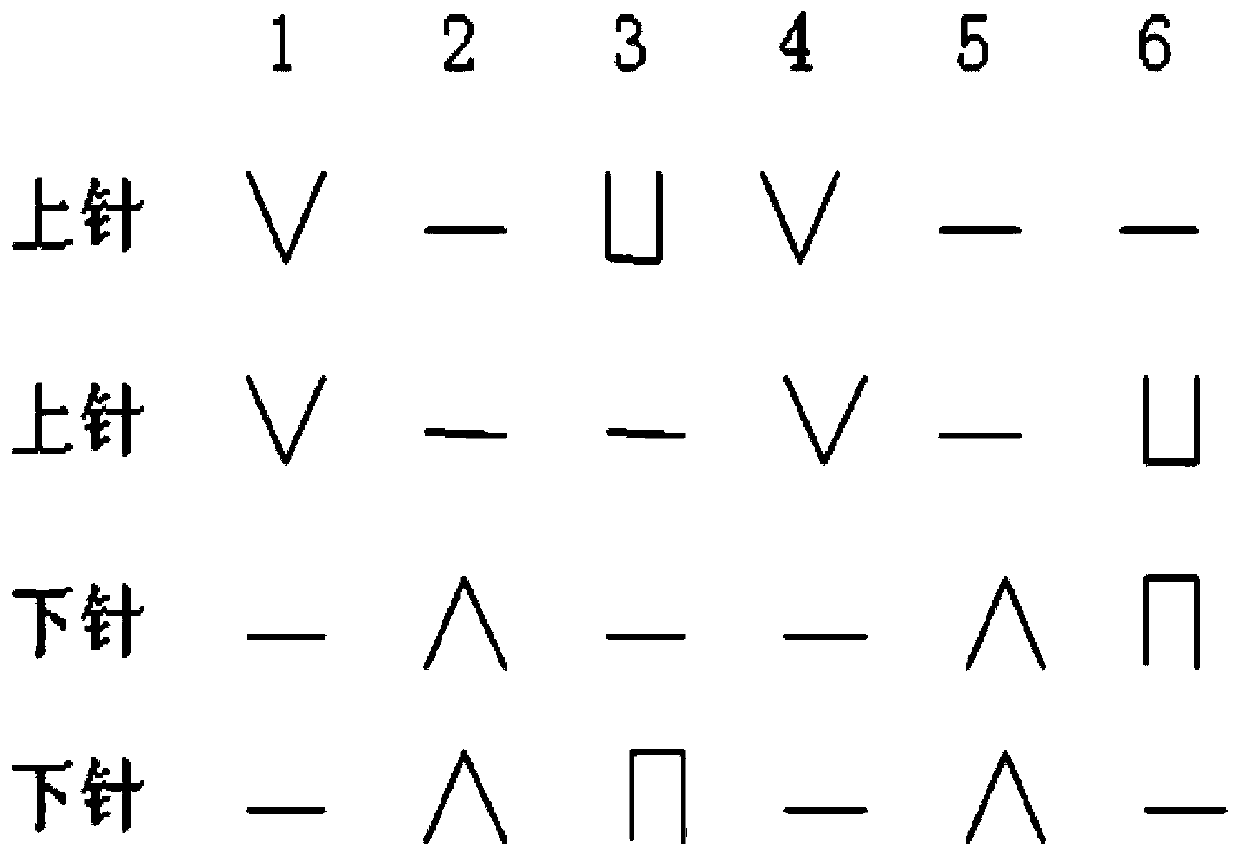

Embodiment 1

[0017] An anti-snag polyester air layer fabric, including an outer layer, a connecting layer and an inner layer, the outer layer and the inner layer are connected through the connecting layer, the fabric is woven by a weft-knitted double-sided machine, and includes an upper dial and a lower needle cylinder , which consists of six circuits to form a cycle, in which the first circuit is sequentially the upper needle forming a loop, the upper needle forming a circle, the lower needle floating thread, and the lower needle floating thread; the second circuit is the upper needle floating thread, the upper needle floating thread, and the lower needle Knitting, knitting and knitting; the third way is sequentially upper needle tuck, upper needle floating thread, lower needle floating thread, lower needle tuck; the fourth way is upper needle forming a loop, upper needle forming a loop, lower needle Floating thread, lower needle floating thread; the fifth way is the upper needle floating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coil length | aaaaa | aaaaa |

| Coil length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com