Modified hot melt pressure-sensitive adhesive coated at low temperature and preparation method thereof

A hot-melt pressure-sensitive adhesive modification technology, applied in the direction of adhesives, rosin adhesives, wax adhesives, etc., can solve the problems of thermal degradation of polymers, achieve excellent low-temperature performance, improve creep resistance, The effect of reducing the threading phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

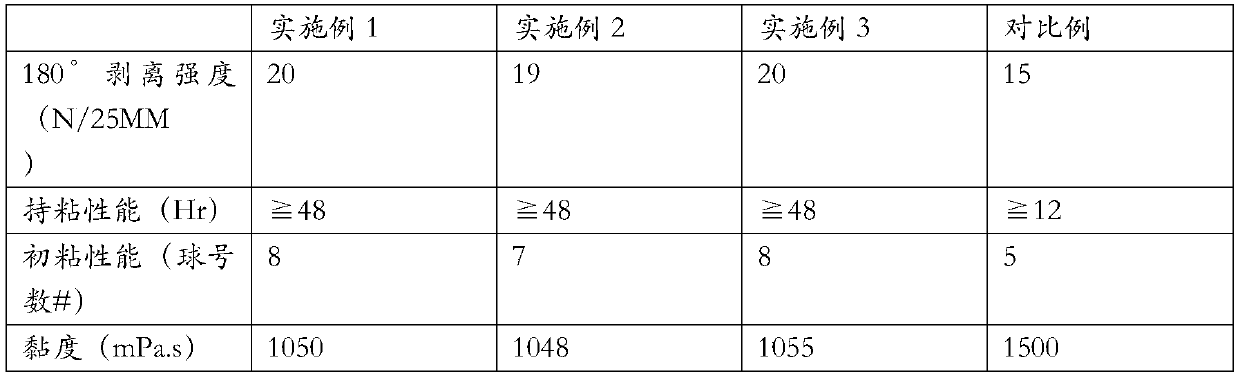

Examples

Embodiment 1

[0017] A modified hot-melt pressure-sensitive adhesive coated at low temperature, prepared from the following components in parts by mass: 40 parts of styrene-butadiene-styrene block copolymer, styrene-butadiene block 30 parts of copolymer, 50 parts of hydrogenated rosin glyceride, 30 parts of tall oil rosin glyceride, 5 parts of alkylated diphenylamine and its mixture, 20 parts of dimerized abietic acid, 30 parts of hard kaolin-hydrated aluminum silicate, 10 parts fumed silicon dioxide, 10 parts zinc oxide, 60 parts No. 52 paraffin, 15 parts glycerol.

[0018] The preparation method of the modified hot-melt pressure-sensitive adhesive of a kind of low-temperature coating, is characterized in that, comprises the following steps:

[0019] 1) Install a stirrer, thermometer, nitrogen conduit and water bath heating device on the three-necked flask, add styrene-butadiene-styrene block copolymer and styrene-butadiene block copolymer to the three-necked flask and add water to dissolv...

Embodiment 2

[0027] A modified hot-melt pressure-sensitive adhesive coated at low temperature, prepared from the following components in parts by mass: 50 parts of styrene-butadiene-styrene block copolymer, 50 parts of styrene-butadiene block copolymer 60 parts of copolymer, 25 parts of hydrogenated rosin glyceride, 40 parts of tall oil rosin glyceride, 5 parts of alkylated diphenylamine and its mixture, 25 parts of dimerized abietic acid, 25 parts of hard kaolin-hydrated aluminum silicate, 115 parts of fumed silicon dioxide, 5 parts of zinc oxide, 70 parts of No. 52 paraffin, and 10 parts of glycerol.

[0028] The preparation method of the modified hot-melt pressure-sensitive adhesive of a kind of low-temperature coating, is characterized in that, comprises the following steps:

[0029] 1) Install a stirrer, thermometer, nitrogen conduit and water bath heating device on the three-necked flask, add styrene-butadiene-styrene block copolymer and styrene-butadiene block copolymer to the three...

Embodiment 3

[0037] A modified hot-melt pressure-sensitive adhesive coated at low temperature, prepared from the following components in parts by mass: 50 parts of styrene-butadiene-styrene block copolymer, 50 parts of styrene-butadiene block copolymer 40 parts of copolymer, 35 parts of hydrogenated rosin glyceride, 35 parts of tall oil rosin glyceride, 7 parts of alkylated diphenylamine and its mixture, 25 parts of dimerized abietic acid, 25 parts of hard kaolin-hydrated aluminum silicate, Fumed silicon dioxide 12 parts, zinc oxide 7 parts, No. 52 paraffin 50 parts, glycerin 10 parts.

[0038] The preparation method of the modified hot-melt pressure-sensitive adhesive of a kind of low-temperature coating, is characterized in that, comprises the following steps:

[0039] 1) Install a stirrer, thermometer, nitrogen conduit and water bath heating device on the three-necked flask, add styrene-butadiene-styrene block copolymer and styrene-butadiene block copolymer to the three-necked flask and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com