A fast self-test method for fiber optic gyroscope startup

A fiber optic gyroscope and self-inspection technology, which is applied to Sagnac effect gyroscopes, measuring devices, instruments, etc., can solve problems such as inability to guarantee the normal operation of the fiber optic gyroscope, unfavorable control of the size of the circuit board, and abnormal operation of the fiber optic gyroscope. The effect of reliable detection results, fast detection speed, and no increase in complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

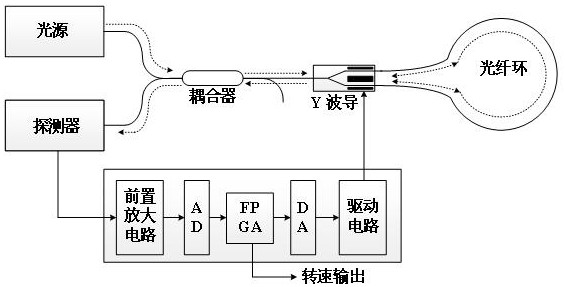

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing of description:

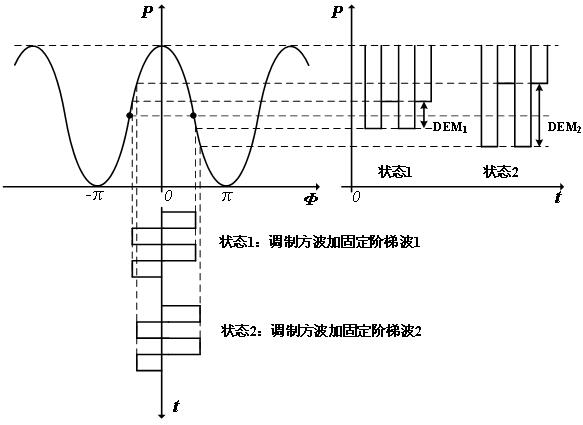

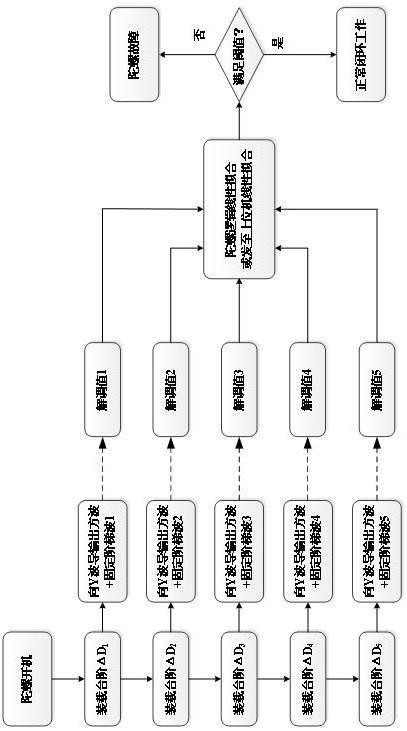

[0034] Such as image 3 As shown, in order to ensure the accuracy of the loop gain test, the step height of the ladder wave is selected as 5 types, and at the same time, it can ensure the high-speed detection without affecting the normal work after the power-on detection. After the fiber optic gyroscope is powered on, it sends The step height is , , , , At the same time, the modulated square wave is sent to the Y waveguide. In order to minimize the influence of the ladder wave on the follow-up work of the fiber optic gyroscope, the height of the steps sent should be reduced in turn. An applicable combination of the step height of the ladder wave is: 10bits , 8bits, 6bits, 4bits, 2bits, but it needs to be adjusted according to different types of fiber optic gyroscopes. The above combination of step heights can be basically satisfied, the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com