Test system for simulating transient unloading of excavation of chamber face under different geostress conditions

A test system and transient unloading technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of unmeasurable displacement of surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

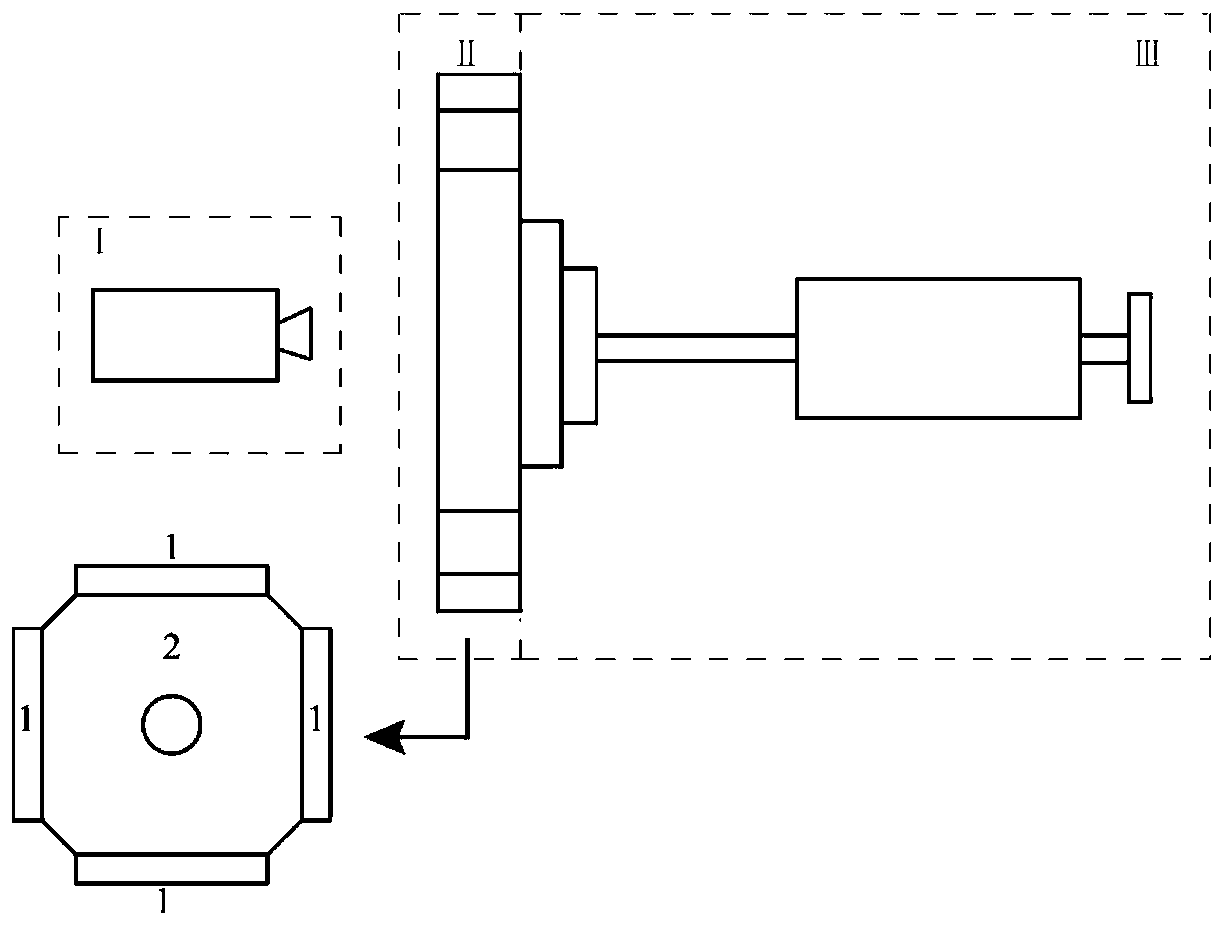

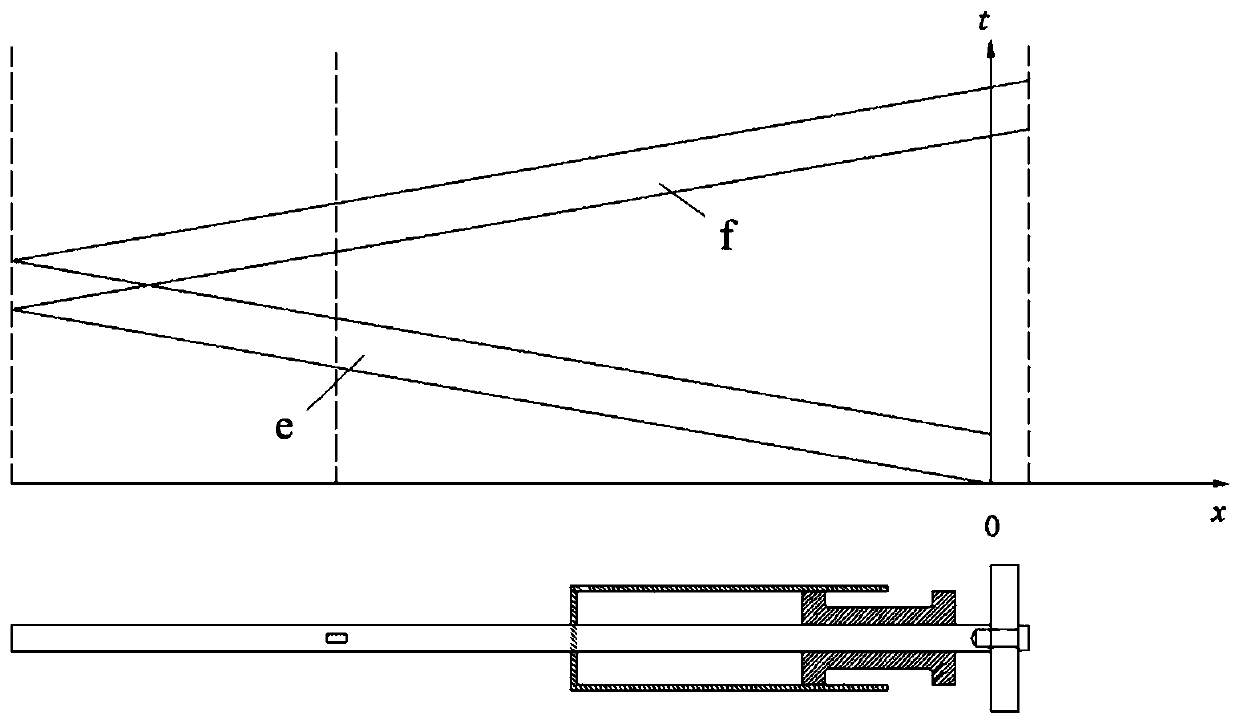

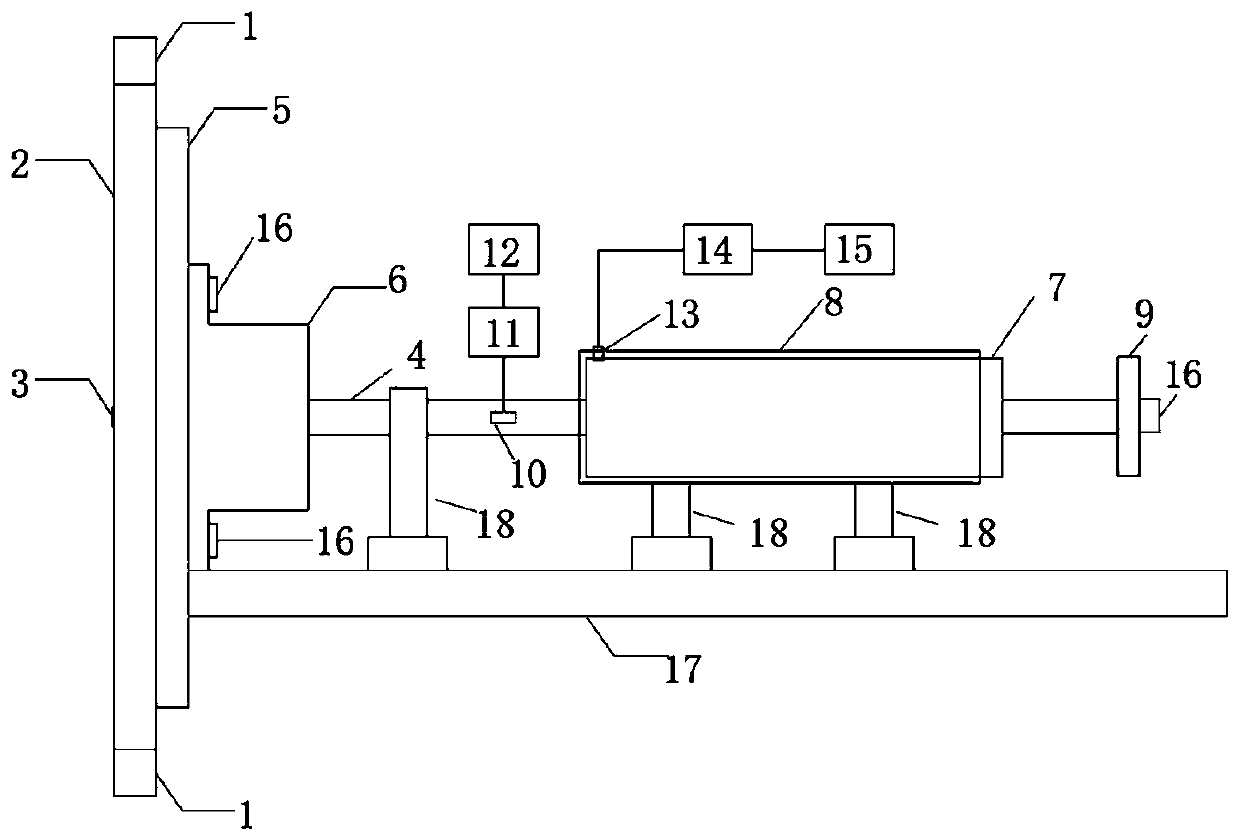

[0047] Such as figure 1 As shown, the test system for simulating the transient unloading of tunnel face excavation under different ground stress conditions in the present invention mainly includes three parts: the in-situ stress simulation device II, the transient unloading device III and the surrounding rock full field Displacement monitoring device Ⅰ; in this test system, the surrounding rock model 2 of the chamber clamps its four loading surfaces (a, b, c, d) by the ground stress loading device 1 in the in-situ stress simulation device Ⅱ and applies load, so the surrounding rock model 2 of the chamber is subjected to plane stress. Among them, the hole in the chamber surrounding rock model 2 is filled by the plug body 3 in the transient unloading device III, and the ground stress is transmitted to the plug body 3 through the hole; after loadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com