An intelligent picking optimization system

An intelligent and optimized module technology, applied in data processing applications, forecasting, computing and other directions, can solve problems such as scheduling, difficult maintenance, and difficult rectification, etc., to reduce workload differences, high operating efficiency, and fast computing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below according to the accompanying drawings.

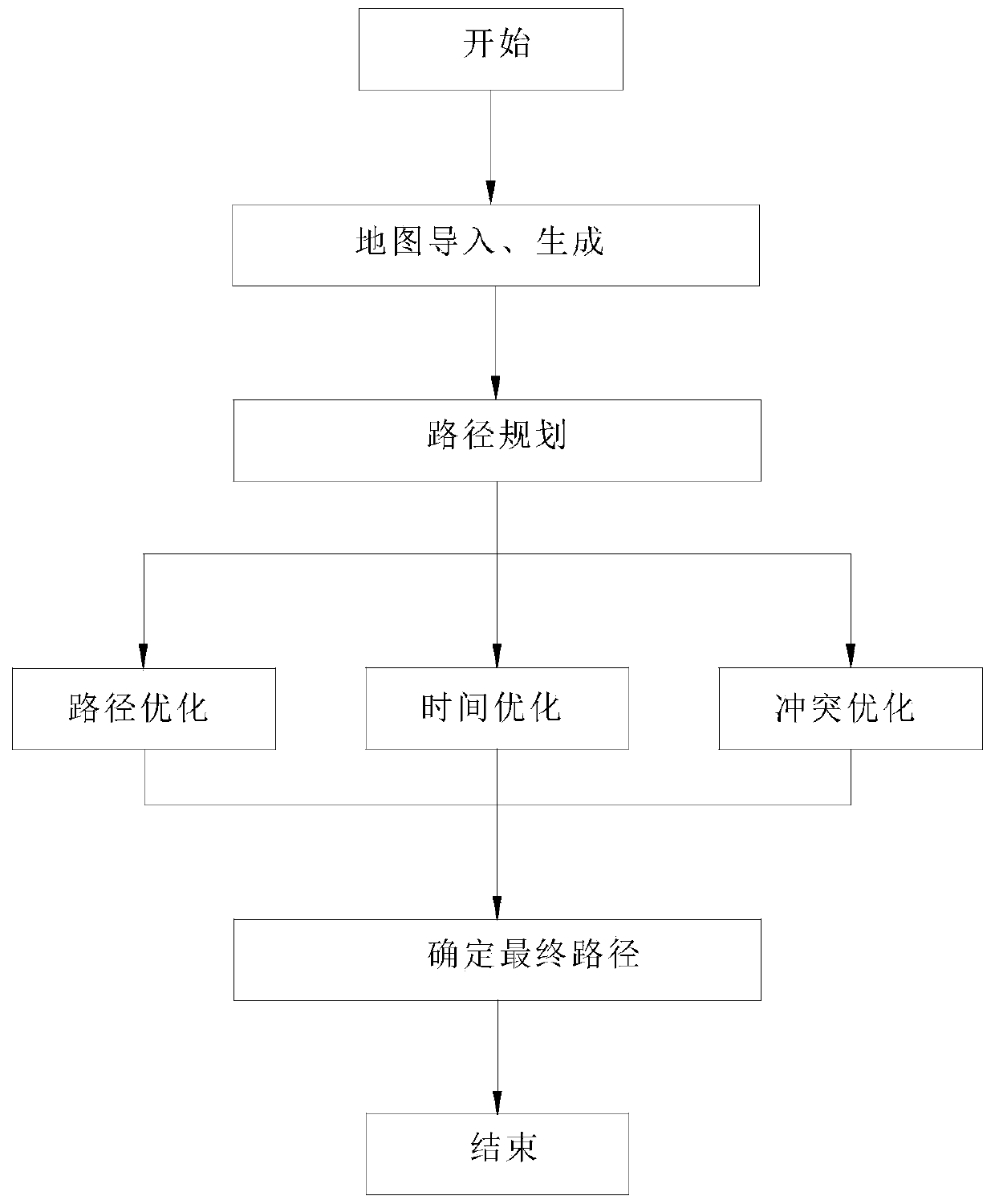

[0055] Such as figure 1 As shown, the map generation module, the path planning module, the path time planning module, and the time conflict optimization module are connected through software communication, and control the operation of the AGV trolley through wireless communication; the specific workflow of the optimization system is as follows:

[0056] (1) start;

[0057] (2) According to the actual working warehouse situation, start to import and generate the map;

[0058] (3) Input the AGV car task;

[0059] (4) carry out path planning, described path planning comprises path line optimization, path time optimization, path conflict optimization;

[0060] (5) finally get the optimal route;

[0061] (6) END.

[0062] Import generated maps as XML format maps.

[0063] The map is a grid-shaped graph generated by vertical straight lines, and its basic elements are nodes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com