Welding auxiliary device for precision mechanical part machining

A technology of precision machinery and auxiliary devices, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of inconvenient fast switching of fixing methods, imperfect structure, inconvenient fast and convenient movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

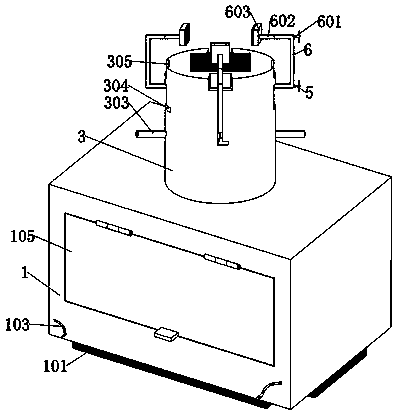

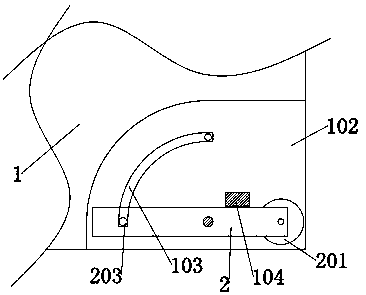

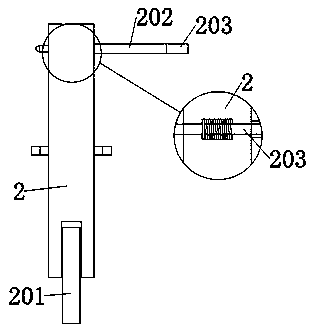

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031]The present invention provides a welding auxiliary device for processing precision mechanical parts, including: a main body 1, an anti-skid pad 101, a turning groove 102, a guide groove 103, a stopper 104, a closing plate 105, a clamping hole 106, and a turning part 2 , moving wheel 201, connecting rod 202, fixed rod 203, rotating member 3, pulley 301, limiting member 302, rotating rod 303, moving groove 304, auxiliary groove 305, moving plate 4, positioning groove 401, clip 402, fixed Part 403, adjusting rod 5, guide plate 501, clamping rod 6, manual rod 601, inner rod 602, fixed head 603 and splint 604; the main body 1 is a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com