Automatic recognition method of transshipment of horizontal transport vehicle and cable crane in concrete construction

A technology for automatic identification and transportation of vehicles, applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve problems such as waste of materials, mistransportation of concrete, and reduction of engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below.

[0030] An automatic identification method for horizontal transport vehicle and cable machine transfer in concrete construction, which comprises the following steps:

[0031] Step 1, install positioning equipment on the cable crane hook girder and the cab of the transport vehicle;

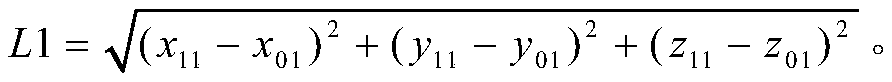

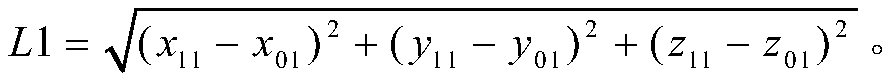

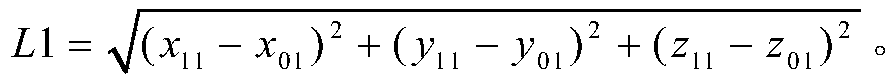

[0032] Step 2, obtain the three-dimensional position P(x0,y0,z0) of the center of the girder of the cable crane hook and the three-dimensional position Q(x1,y1,z1) of the center of the cab of the transport vehicle in real time through the positioning device;

[0033] Step 3, install monitoring equipment at the hydraulic flap of the transport vehicle, and obtain the unloading status N of the transport vehicle in real time. When N=0, it means that it is not unloading, and when N=1, it means that it is unloading;

[0034] Step 4: Obtain the effective maximum distance L between the hook girder of the cable crane and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com