Anti-residue silicone protective film for process

A technology of protective film and residual glue, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of affecting automatic continuous production, poor antistatic effect, low viscosity, etc. , to achieve the effect of solving automatic continuous production, not easy to warp or even fall off, and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

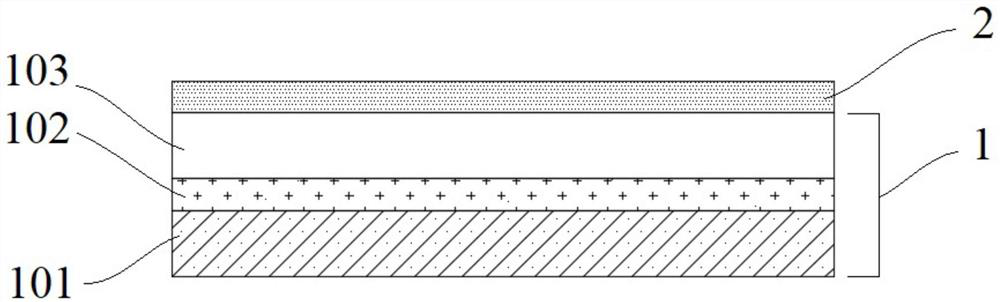

[0035] Embodiments 1 to 4: A kind of anti-residue silicone protective film for manufacturing process, including a substrate layer 1 and an organic silica gel layer 2 coated on the surface of the substrate layer 1, and the substrate layer 1 further includes a PET film 101 and PE Film 103, this PET film 101 and PE film 103 are combined together by an adhesive layer 102;

[0036] The thickness of the PET film 101 is 20 μm, the thickness of the PE film 103 is 20 μm, the thickness of the adhesive layer 102 is 10 μm, and the thickness of the silicone layer 2 is 15 μm;

[0037] The adhesive layer 102 is a polyester adhesive layer.

[0038] The organic silica gel layer 2 is specifically composed of the following components in parts by weight:

[0039] components Example 1 Example 2 Example 3 Example 4 Methyl vinyl silicone rubber 270 200 300 350 polyisoprene rubber 40 15 30 20 silicone resin 10 20 25 15 Vinyl silicone oil 6 5 4 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com