Preparation method of antistatic silica gel protective film

A protective film and antistatic technology, applied in the direction of film/flaky adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of affecting automatic continuous production, poor antistatic effect, low viscosity, etc. , to achieve the effect that it is not easy to warp or even fall off, improve the antistatic effect, and have strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0025] Embodiment 1~4: a kind of preparation method of antistatic silica gel protective film, comprises the following steps:

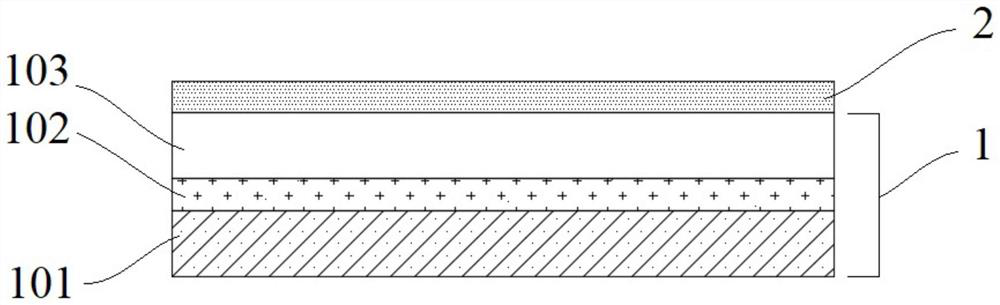

[0026] S1. Coating an adhesive on the surface of a PET film 101, drying to form an adhesive layer 102, and then hot-compressing the PET film 101 and a PE film 103 to obtain a substrate layer 1;

[0027] S2. Methyl vinyl silicone rubber, polyisoprene rubber, silicone resin, vinyl silicone oil, hydrogen-containing silicone oil, 3-thiocyanatopropyltriethoxysilane, 2-aminobenzimidazole, nano Mix graphite powder, potassium monododecyl phosphate, toluene and ethyl acetate evenly, stir for 30-60 minutes, then add methyl butynol, platinum catalyst, cyclohexanone peroxide, and stir for 10-20 minutes to obtain organic Silicone adhesive;

[0028] S3. uniformly coating the silicone adhesive on the surface of the substrate layer 1, and curing it at 140-150° C. to form the silicone layer 2 to obtain a semi-finished protective film;

[0029] S4. Cut the semi-finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com