Preparation process of adhesive-residue-preventing adhesive tape

一种制备工艺、胶带的技术,应用在防残胶胶带的制备工艺领域,能够解决易翘边、抗静电效果不佳、拉断等问题,达到降低人力与时间成本、提升抗静电效果、剥离力适中的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

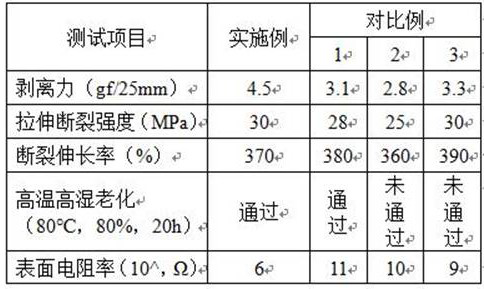

Examples

Embodiment

[0017] Embodiment: a kind of preparation technology of anti-residue adhesive tape, comprises the following steps:

[0018] S1. Coating an adhesive on the surface of a PET film, drying to form an adhesive layer, and then hot-compressing the PET film and a PE film to obtain a substrate layer;

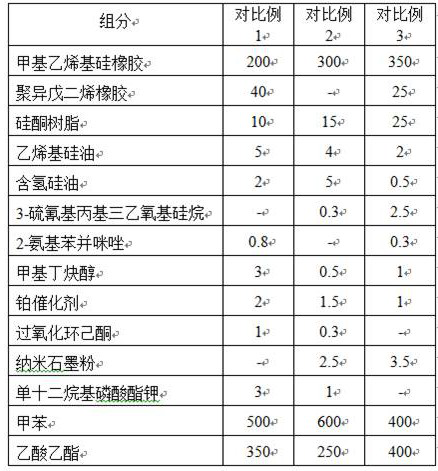

[0019] S2. Methyl vinyl silicone rubber, polyisoprene rubber, silicone resin, vinyl silicone oil, hydrogen-containing silicone oil, 3-thiocyanatopropyltriethoxysilane, 2-aminobenzimidazole, nano Mix graphite powder, potassium monododecyl phosphate, toluene and ethyl acetate evenly, stir for 30-60 minutes, then add methyl butynol, platinum catalyst, cyclohexanone peroxide, and stir for 10-20 minutes to obtain organic Silicone adhesive;

[0020] S3. uniformly coating the silicone adhesive on the surface of the substrate layer, curing at 140-150°C to form a silicone layer, and preparing a semi-finished protective film;

[0021] S4. Cut the semi-finished product of the protective film into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com