Self-resetting one-way sliding tensile support seat

A self-resetting and slipping technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of small friction coefficient, low comprehensive stiffness, and large additional stress on rails, achieve good economical practicability and promotion prospects, and reduce replacement costs. The effect of maintenance cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

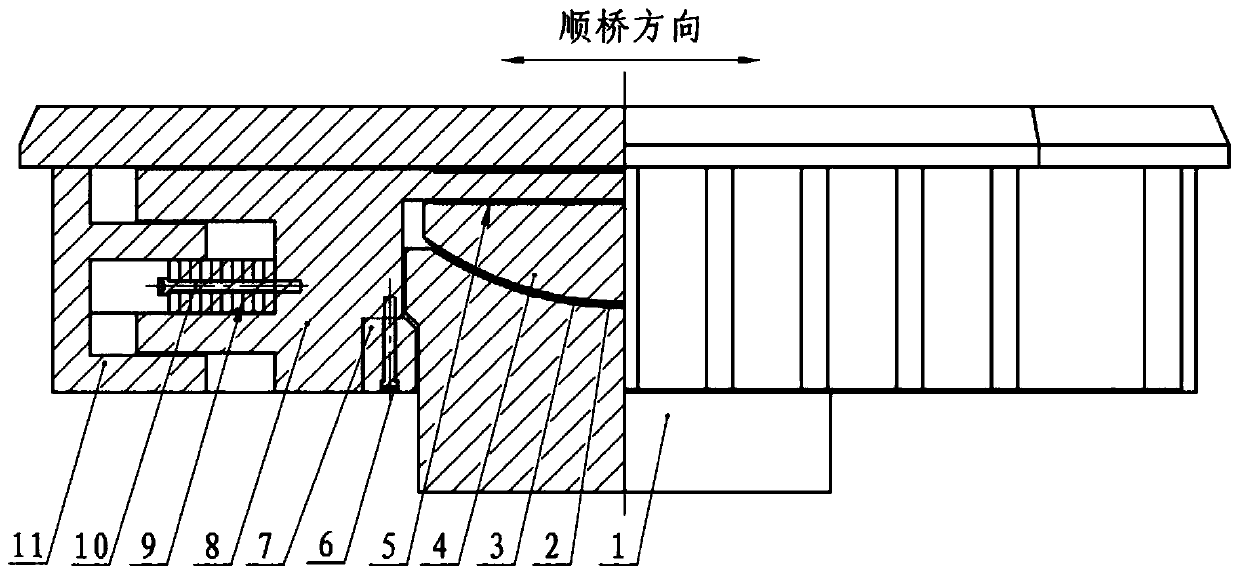

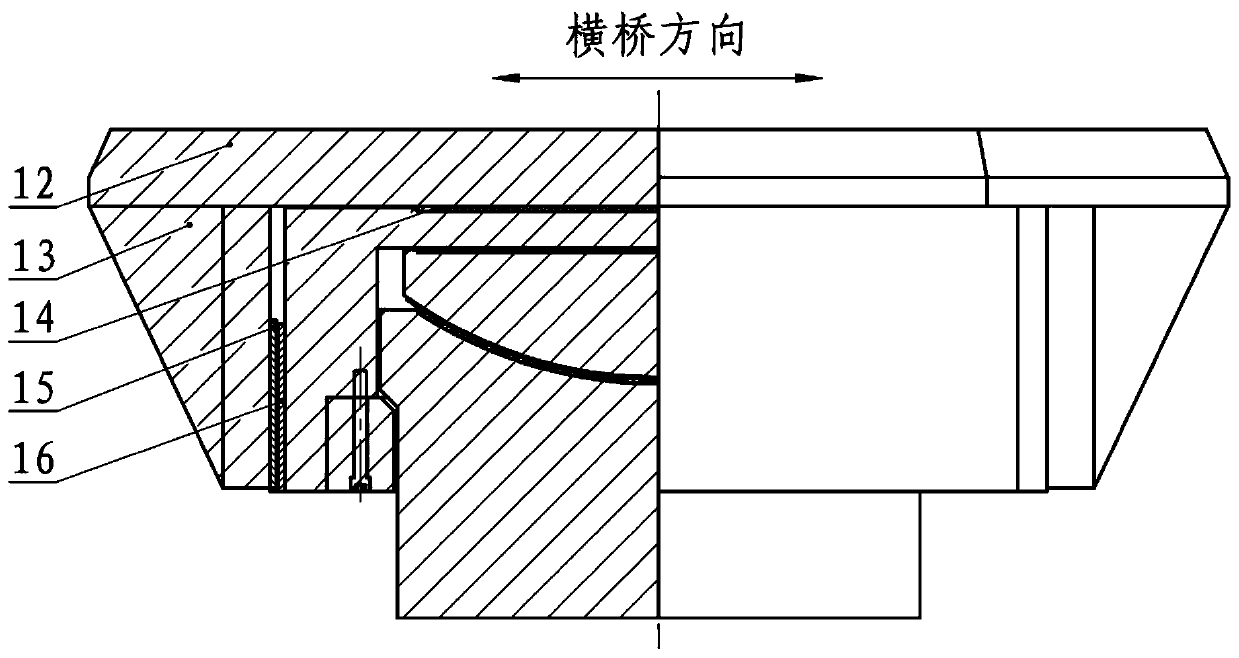

[0032] refer to figure 1 and figure 2 , a self-resetting one-way sliding tensile bearing, comprising a lower bearing plate 1, a spherical sliding plate 2, a spherical crown lining plate 4, an intermediate lining plate 8 and an upper bearing plate 12, the bottom of the lower bearing plate 1 Used for welding and fixing with the pier foundation, the spherical sliding plate 2 is installed on the upper part of the lower bearing plate 1, the spherical crown lining plate 4 is installed in the spherical sliding plate 2, and the spherical crown lining plate 4 can slide in the spherical sliding plate 2 To meet the requirements of the large corner of the bridge, the lower side of the intermediate liner 8 is located above the spherical crown liner 4, the upper side of the intermediate liner 8 is located below the upper support plate 12, and the upper support plate 12 is used for welding with the bridge body. The middle liner 8 is fixed with a leaf spring assembly 9 along the bridge to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com