Turbulent flow column structure used for reinforced heat exchange of turbine blade

A technology that enhances heat transfer and turbine blades, and is applied to blade support components, engine components, machines/engines, etc. It can solve problems such as the deterioration of the working environment of high-temperature components, improve heat transfer performance, reduce pressure loss, and increase turbulence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention will be further described.

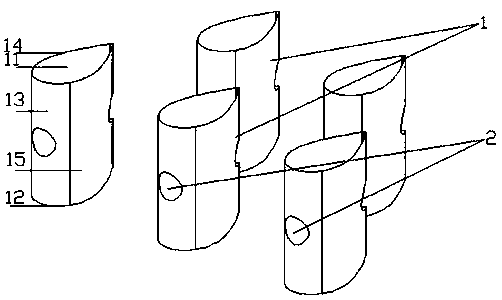

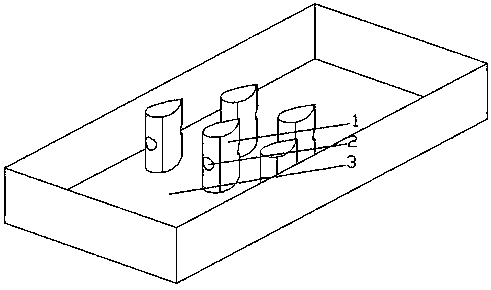

[0022] Such as figure 1 and 2 As shown, a spoiler column structure for enhanced heat transfer of turbine blades includes a spoiler column body 1, the spoiler column body 1 is a column with a drop-shaped cross section, and one end of the drop-shaped shape is a circular arc end, the other end is the apex end, the spoiler body 1 is provided with a penetration hole 2 that runs through the drop-shaped arc end and the apex end transversely, and the penetration hole 2 is located in the longitudinal center of the spoiler body 1 high.

[0023] Preferably, there is only one penetration hole 2 on the spoiler body 1 .

[0024] Specifically, the penetration hole 2 is a horizontally arranged cylindrical through hole, the central axis of the penetration hole 2 is perpendicular to the longitudinal direction of the spoiler column 1 body, and the central axis of the penetration hole 2 is in line wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com