Gearbox of speed changing mechanism

A technology of speed change mechanism and gearbox, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problems affecting the stability of the output shaft, shock and vibration, etc., and achieve the effect of ensuring smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

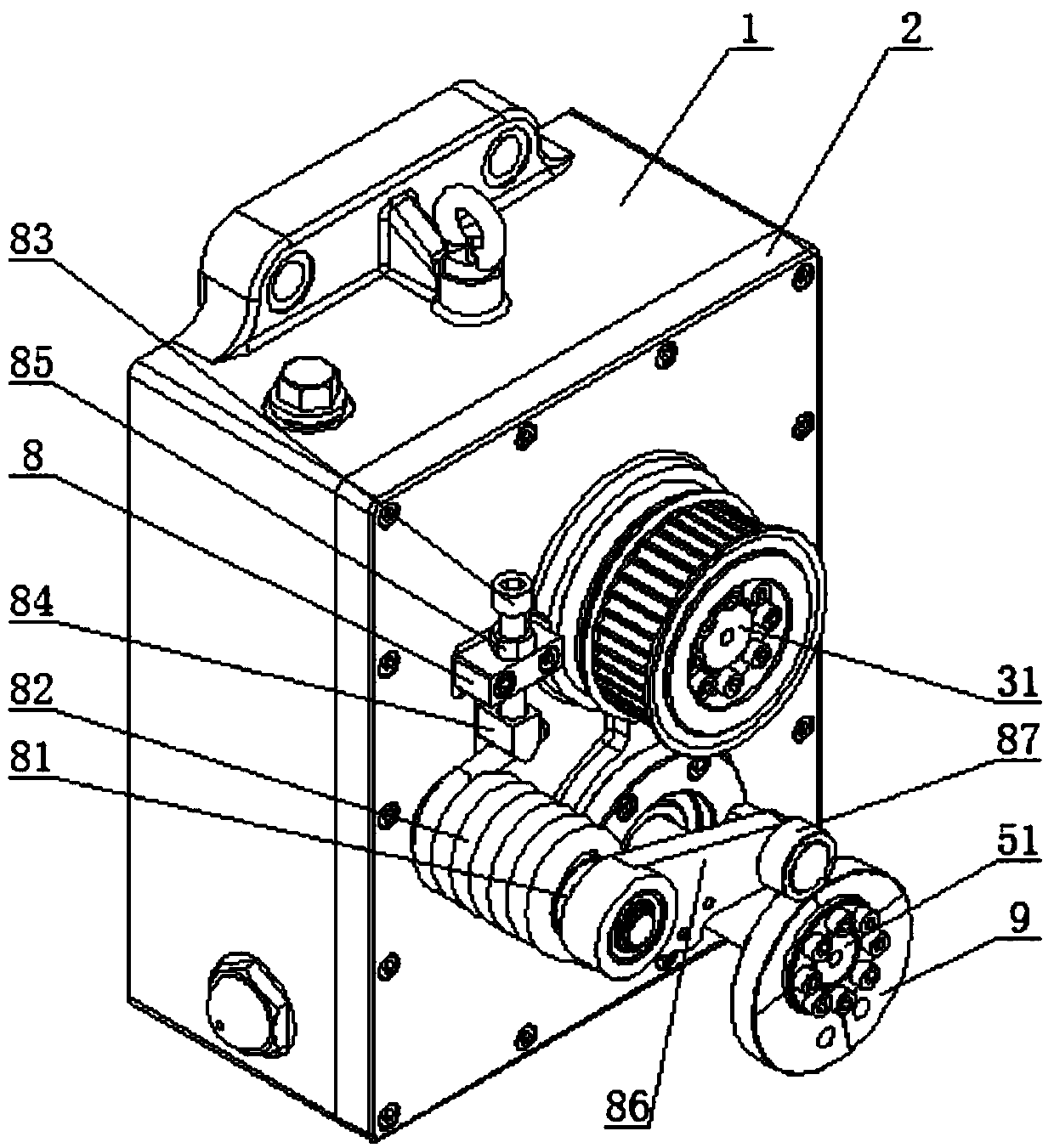

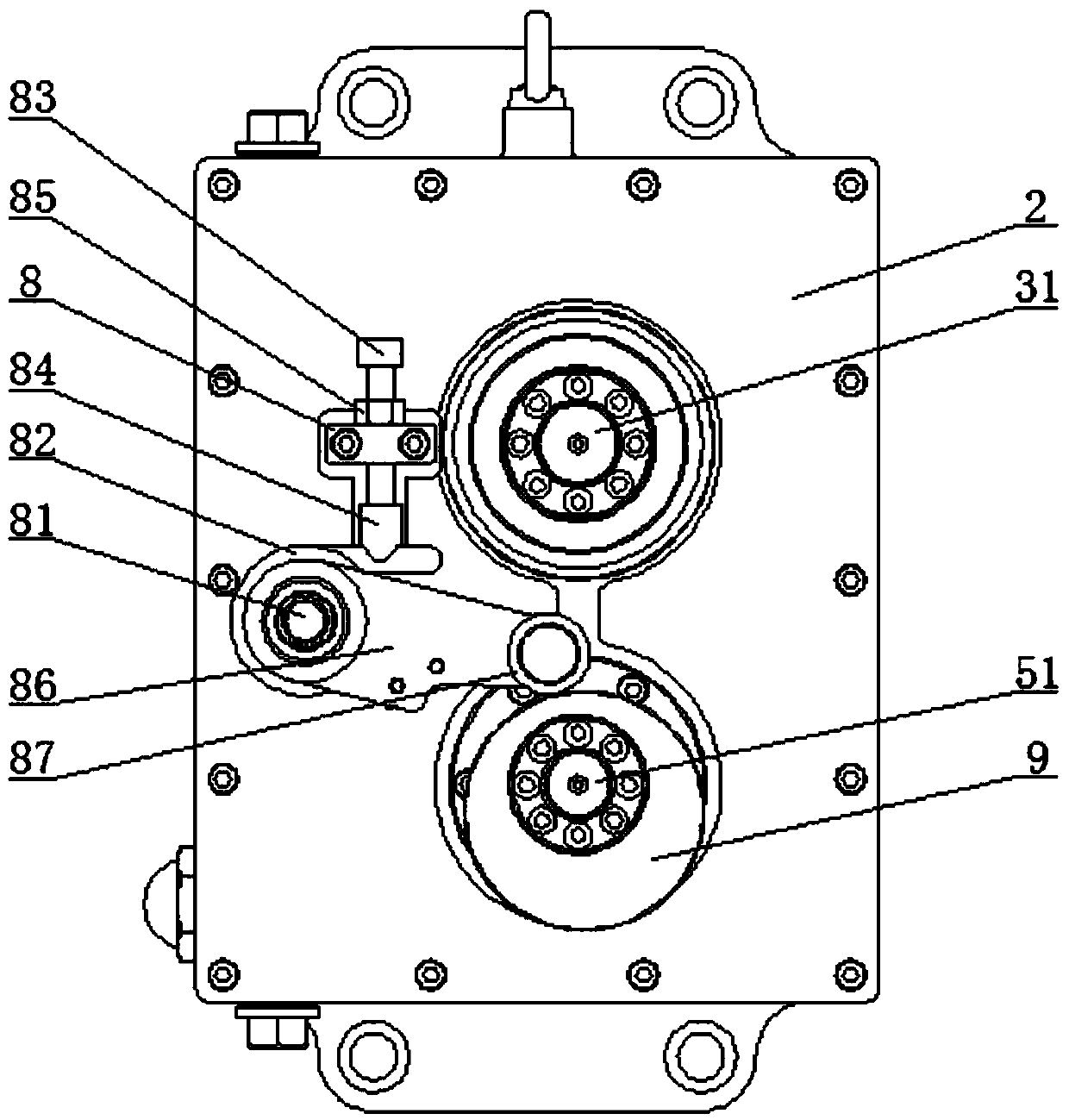

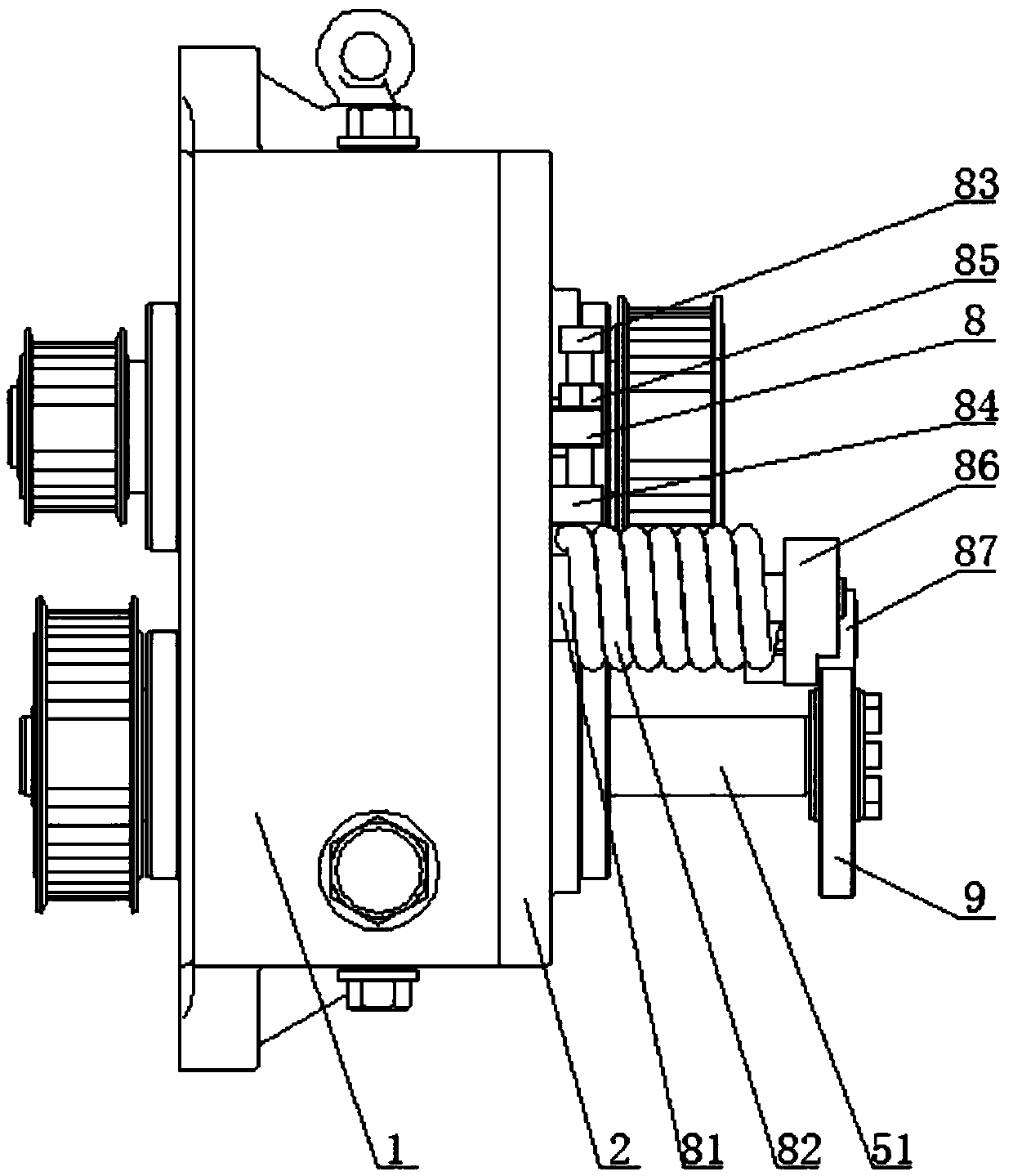

[0014] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0015] Such as Figure 1 to Figure 4 As shown, the gear box of the speed change mechanism includes a box body 1 and a box cover 2, and the inside of the box body 1 is provided with a driving gear 3, a bridge gear 4 and a driven gear 5, and the driving gear 3 and the bridge gear 4 mesh , the driving gear 3 is an eccentric gear, the driving shaft 31 is pierced on the driving gear 3, the bridge gear 4 and the driven gear 5 are meshed, the driven gear 5 is pierced with a driven shaft 51, and the driving gear 3 The center distance between the bridge gear 4 and the bridge gear 4 is constrained by the first connecting rod 6, and the center distance between the bridge gear 4 and the driven gear 5 is constrained by the second connecting rod 7, which ensures reliable operation between the gears.

[0016] The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com